Manufacturing method of thermal head unit, thermal head unit thereof and printer comprising the same

A manufacturing method, thermal head technology, applied in printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment embodying the present invention will be described in detail with reference to the drawings.

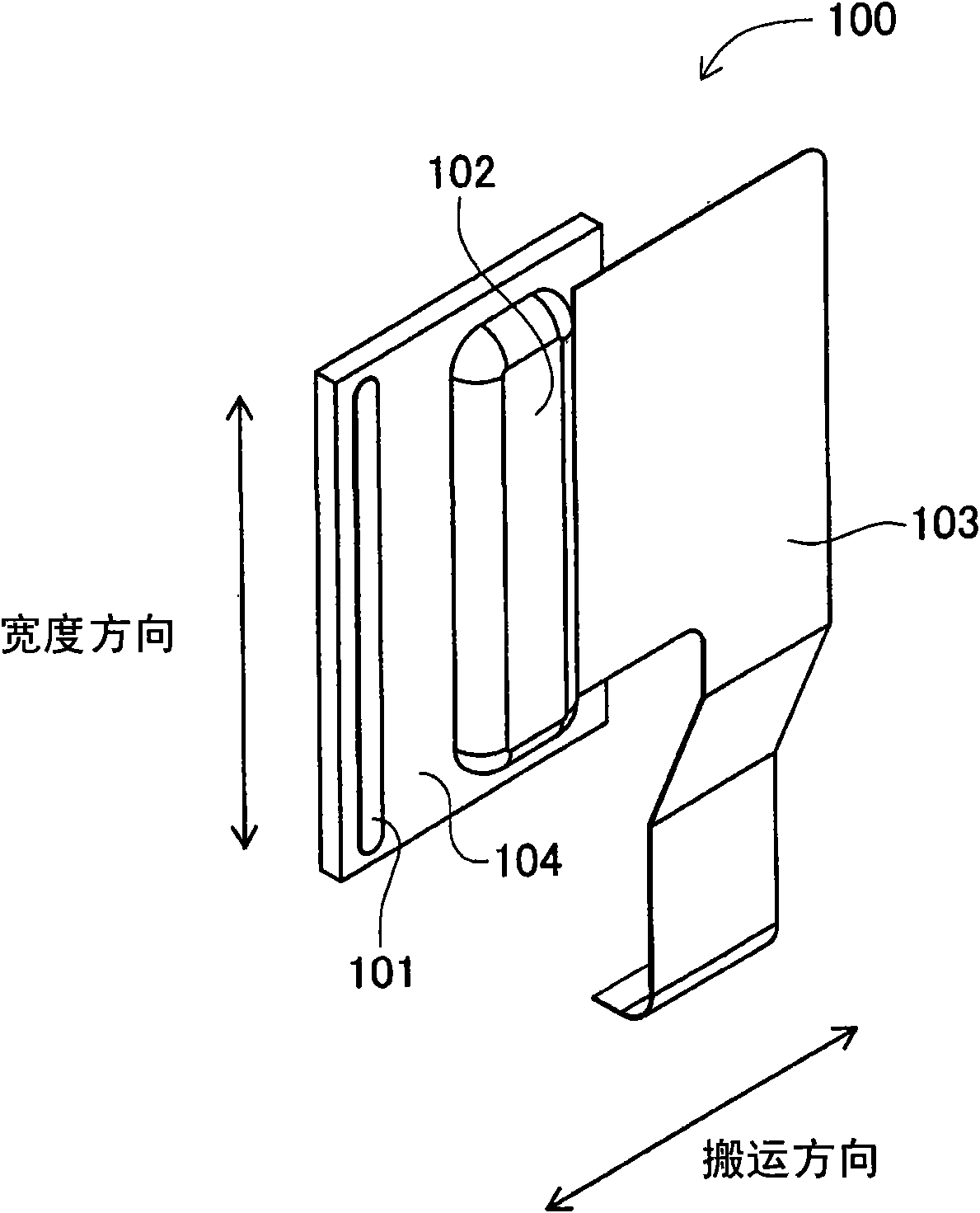

[0032] figure 1 Indicates the thermal head that makes up the thermal head unit. Such as figure 1 As shown, the thermal head 100 is composed of a heating part 101 , a circuit part 102 , a wiring part 103 , and a main body part 104 .

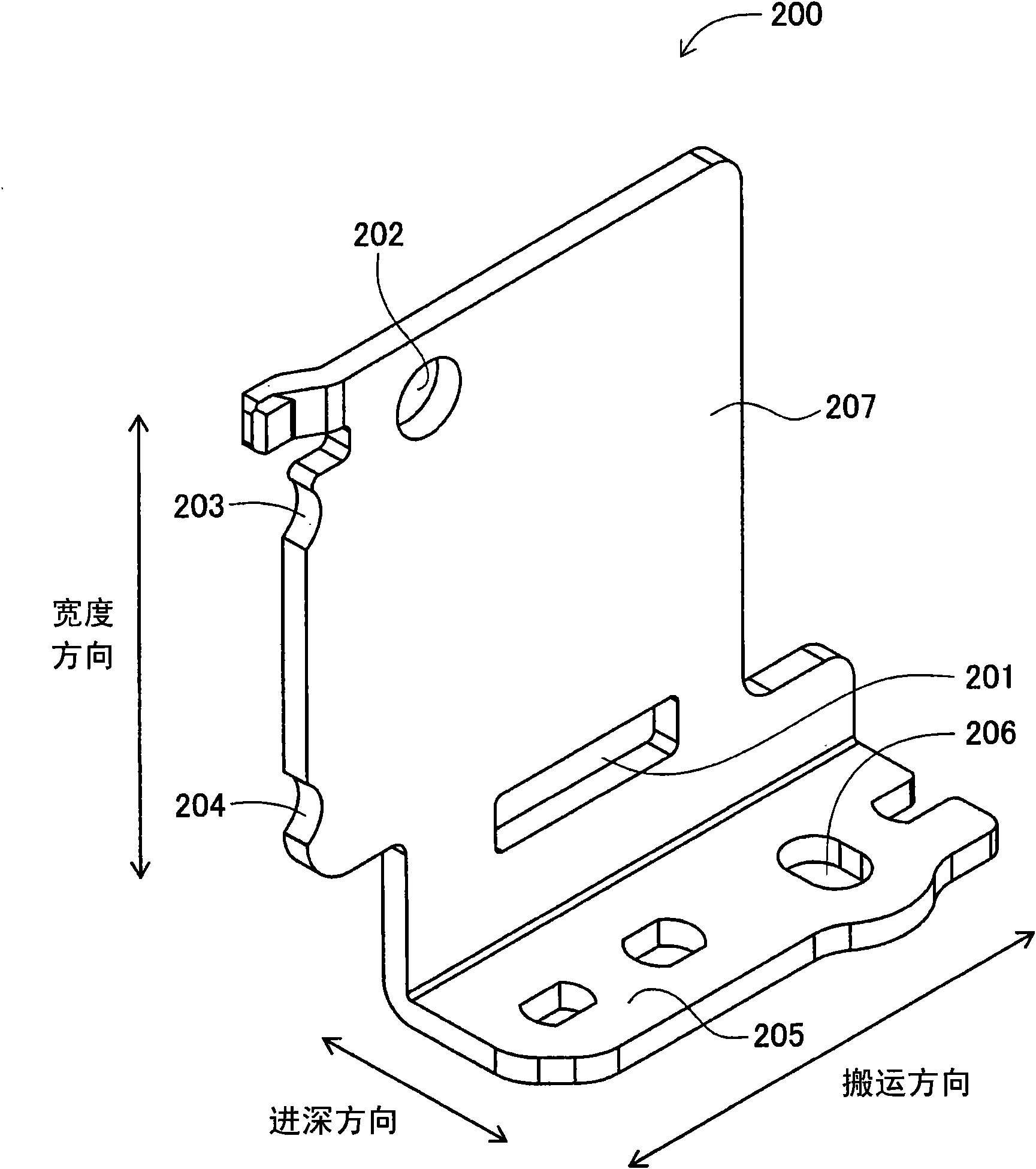

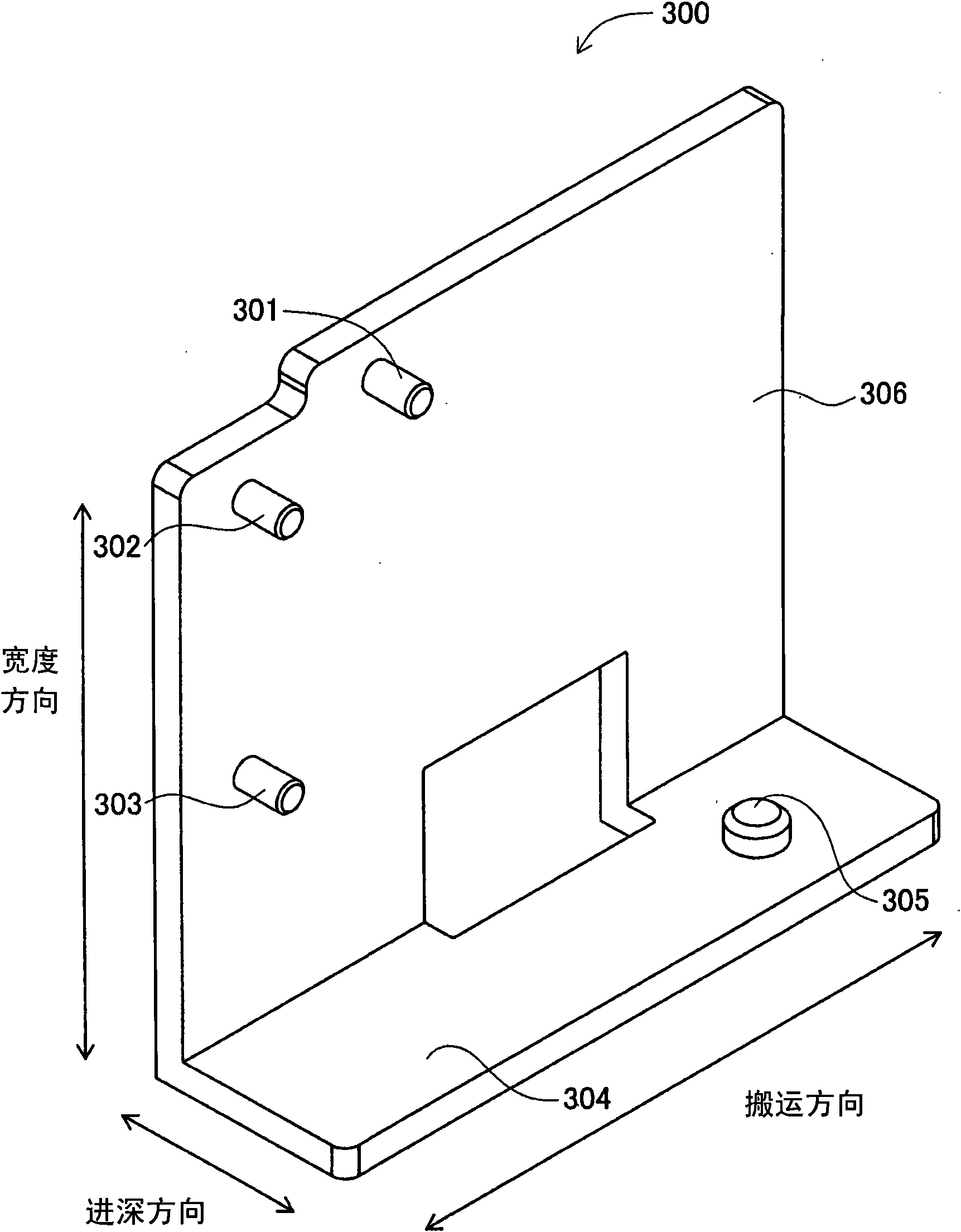

[0033] In addition, the following for convenience, such as Figure 7 As shown, the vertical direction on the paper is referred to as the "width direction", the lower left upper right direction on the paper is referred to as the "transportation direction", and the upper left lower right direction on the paper is referred to as the "depth direction". These directions are derived from placing the thermal head unit U (refer to Figure 12 ) is the width direction and conveying direction of the printing medium when it is assembled on the printing device to print on the printing medium.

[0034] The heat generating unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com