Plate clamper platform for falling weight impact test, and impact speed measurement method

A drop weight impact test and plate fixture technology, which is applied to devices using optical methods, measuring devices, analyzing materials, etc., can solve the difficulty of increasing the speed-time curve acquisition, affecting the measurement accuracy of the force sensor, and the complex calculation process. and other problems to achieve the effect of improving test reliability, improving measurement convenience, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

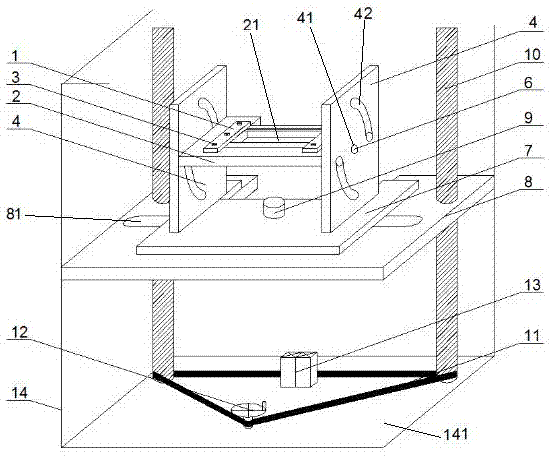

[0040] Such as figure 1 As shown, a plate fixture platform for drop weight impact test, including a fixture structure, a supporting lifting structure and a laser speed measuring device.

[0041] The fixture structure includes a plate clamping device, a multi-angle rotating device and a fixture bottom plate 7 .

[0042] The plate clamping device includes a clip 1 , a splint 2 and a splint fastening bolt 3 .

[0043] The thickness of the splint 2 is at least 20mm, and the recommended size is 25mm. There is a test piece impact groove 21 at the center of the splint 2. The test piece impact groove 21 is preferably a square groove with a depth of 150mm*100mm and a depth of 4mm.

[0044] The clips are arranged on the splints on both sides of the impact groove of the specimen, and the clips are detachably connected to the splints. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com