Device and method for carrying out stress corrosion experiment in high-temperature liquid-phase corrosion environment

A technology for stress corrosion and corrosive environments, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc. precise control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

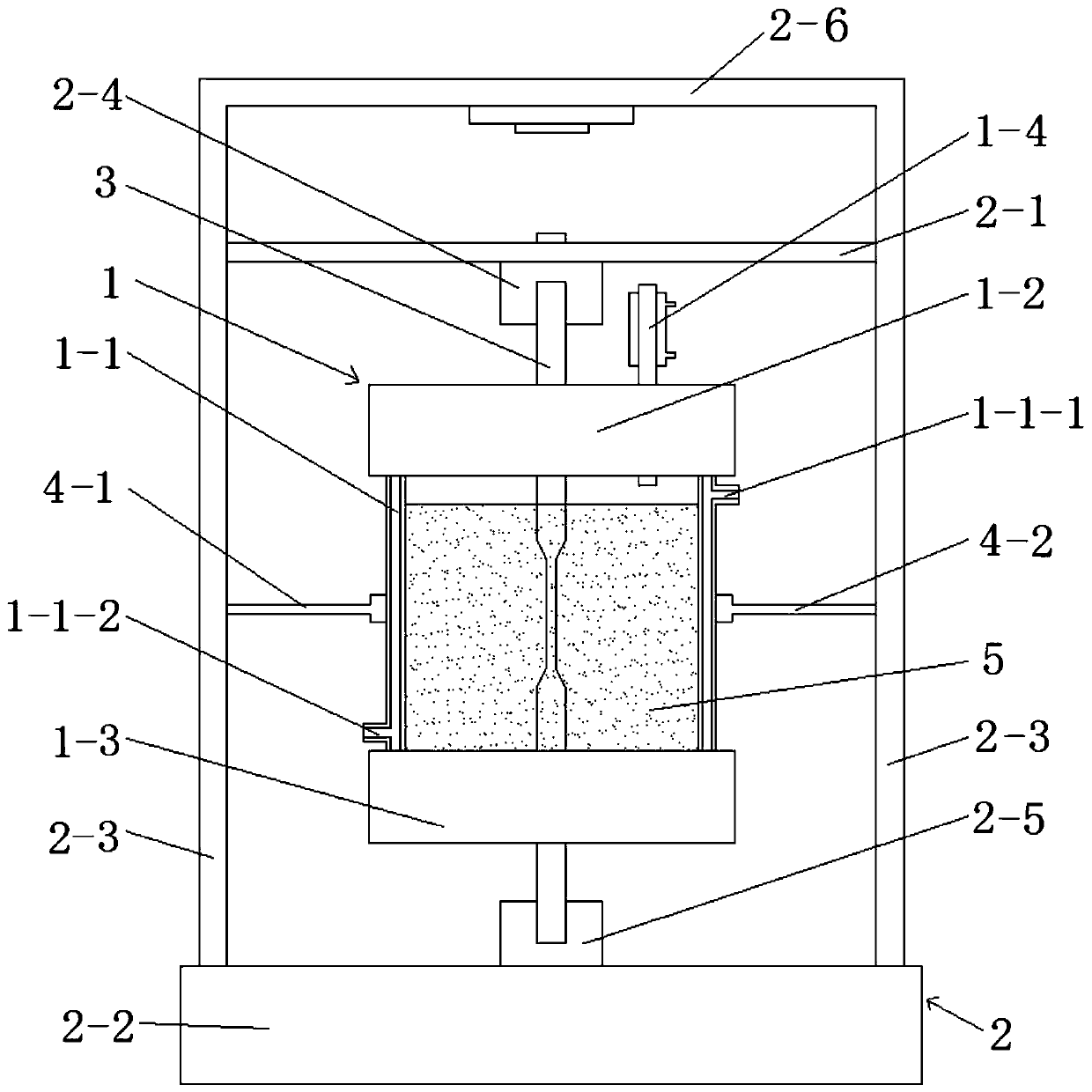

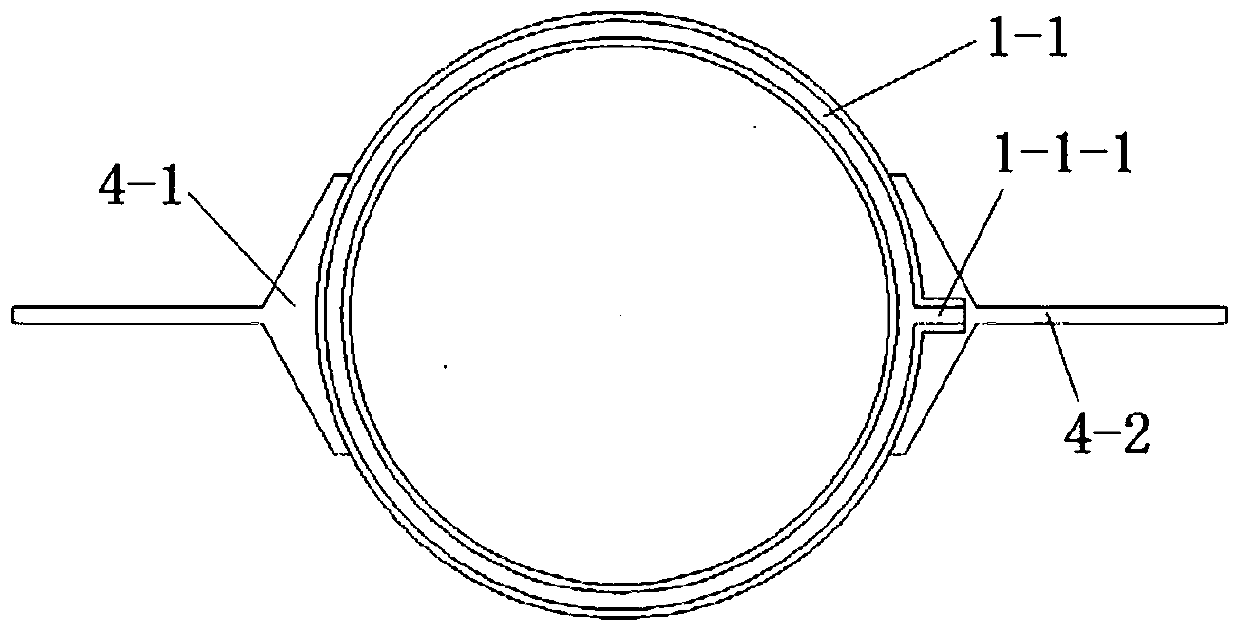

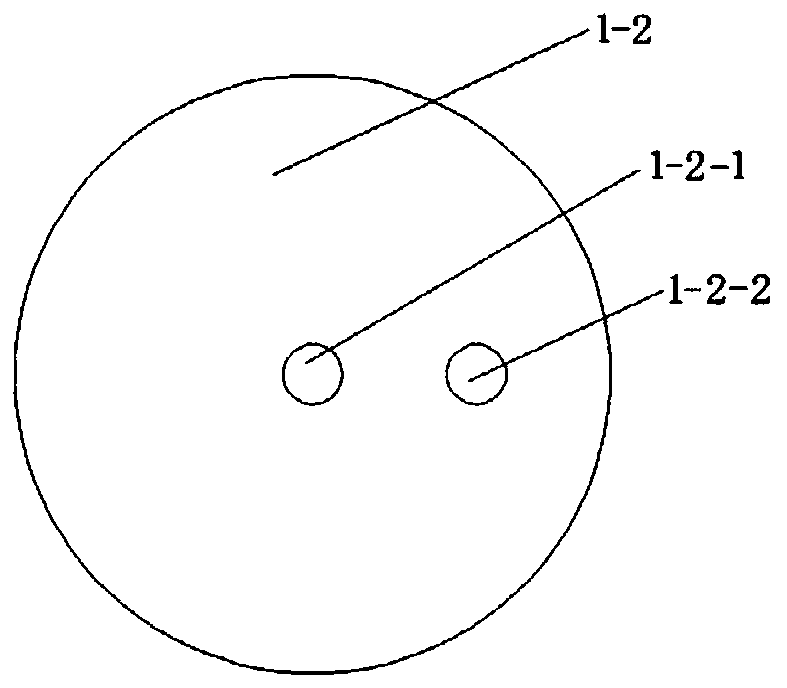

[0045] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the device for performing stress corrosion experiments in the high-temperature liquid phase corrosion environment of this embodiment includes a universal testing machine 2 and a stress corrosion test chamber 1 connected to the universal testing machine 2 through a clamp. The machine 2 includes a workbench 2-2 and two columns 2-3 respectively arranged on the two ends of the table top of the workbench 2-2, and the tops of the two columns 2-3 are connected with the two ends of the fixed beam 2-6 respectively A moving beam 2-1 for loading the stress corrosion test sample 3 is arranged between the upright columns 2-3, and an upper chuck 2-1 connected to the upper end of the stress corrosion test sample 3 is arranged on the moving beam 2-1. 4. The workbench 2-2 is provided with a lower chuck 2-5 connected to the lower end of the stress corrosion test sample 3, and the holder includes a first holder symmetrical...

Embodiment 2

[0057] This embodiment includes the following steps:

[0058] Step 1, process the zirconium alloy metal rod to obtain the experimental rod, the structure and size of which are shown in Figure 5 ;

[0059] Step 2: Clamp and connect the first clamper 4-1 and the second clamper 4-2 provided on the column 2-3 of the universal testing machine 2 to the middle part of the double-layer glass cylinder 1-1. The lower end of the double-layer glass cylinder 1-1 is sealed and connected with the lower plug 1-3, and the short connecting section 3-2 of the experimental rod obtained in step 1 is inserted into the lower plug sample of the lower plug 1-3. Hole 1-3-1 and keep it sealed, inject the nitric acid solution with a mass concentration of 6mol / L into the double-layer glass cylinder 1-1, keep the rod gauge section 3-3 of the experimental rod completely immersed in the nitric acid solution, The upper end of the double-layer glass cylinder 1-1 is sealed and connected with the upper plug h...

Embodiment 3

[0066] This embodiment includes the following steps:

[0067] Step 1, process the 304L stainless steel metal plate to obtain the experimental plate;

[0068] Step 2: Clamp and connect the first clamper 4-1 and the second clamper 4-2 provided on the column 2-3 of the universal testing machine 2 to the middle part of the double-layer glass cylinder 1-1. The lower end of the double-layer glass cylinder 1-1 is sealed and connected to the lower plug 1-3, and the short clamping section 3-6 of the experimental plate obtained in step 1 is inserted into the lower plug sample of the lower plug 1-3 Through the hole 1-3-1 and keep it sealed, inject the nitric acid solution with a mass concentration of 8mol / L into the double-layer glass cylinder 1-1, and keep the plate gauge section 3-7 of the test plate completely immersed in the nitric acid solution , the upper end of the double-layer glass cylinder 1-1 is sealed with the upper plug 1-2, and the long clamping section 3-8 of the experime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com