Supercritical carbon dioxide stress corrosion experimental device and experimental method

A technology of stress corrosion and carbon dioxide, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of being unable to apply supercritical carbon dioxide stress corrosion and supercritical carbon dioxide stress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

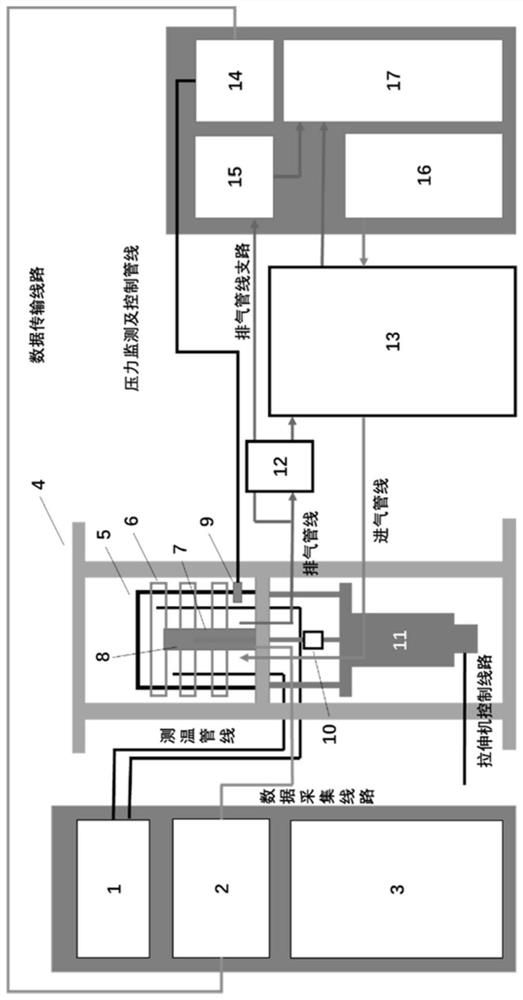

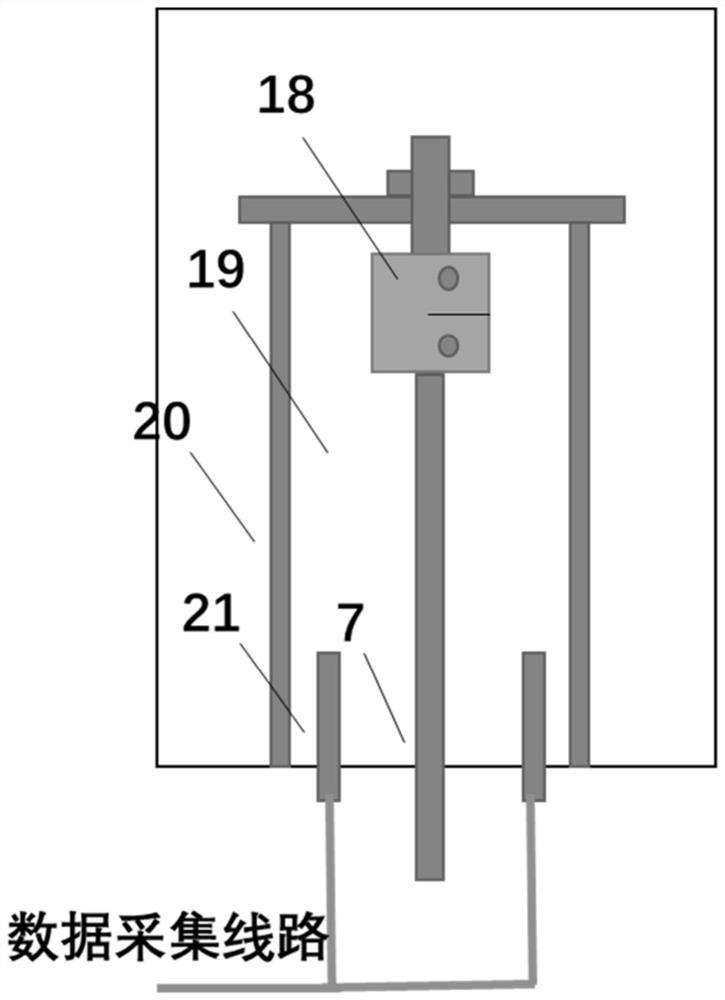

[0048] The supercritical carbon dioxide stress corrosion device reference of embodiment 1 figure 1 . figure 1 It is a schematic diagram of the overall structure of the supercritical carbon dioxide stress corrosion test device in one embodiment of the present invention.

[0049] Such as figure 1 As shown, the supercritical carbon dioxide stress corrosion device of embodiment 1 includes four parts: the first part is the control and recording system, the second part is the high temperature and high pressure experimental circuit, the third part is the gas condensation and on-line monitoring system, and the fourth part is The gas is supplied to the pressure-stabilized discharge system, and the connected arrow indicates the flow direction of the working medium in the pipeline. For the purpose of simplification, valves, connectors, etc. are not marked in the schematic diagram of the device in this embodiment, but it is conceivable that those skilled in the art can make correspondin...

Embodiment 2

[0058] In the supercritical carbon dioxide stress corrosion experimental device in this embodiment, the supercritical carbon dioxide stress corrosion device includes a control and recording system, a high temperature and high pressure experimental circuit, a gas condensation and online monitoring system, and a gas supply and pressure stabilization discharge system, wherein,

[0059] The control and recording system are respectively connected with the high temperature and high pressure experimental circuit and the gas condensation and online monitoring system through pipelines;

[0060] The high temperature and high pressure experimental circuit is used to simulate the experimental conditions of supercritical carbon dioxide stress corrosion;

[0061] The gas condensation and on-line monitoring system is connected to the gas supply and discharge system through the gas pipeline;

[0062] The gas supply and pressure stabilization discharge system is used to maintain the stable gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com