Surface cleaning device

A surface cleaning device and cleaning technology, applied to cleaning equipment, window cleaning, household appliances, etc., can solve the problems of high cost, weakened suction force, complex structure, etc., and achieve strong suction force, smooth air path, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

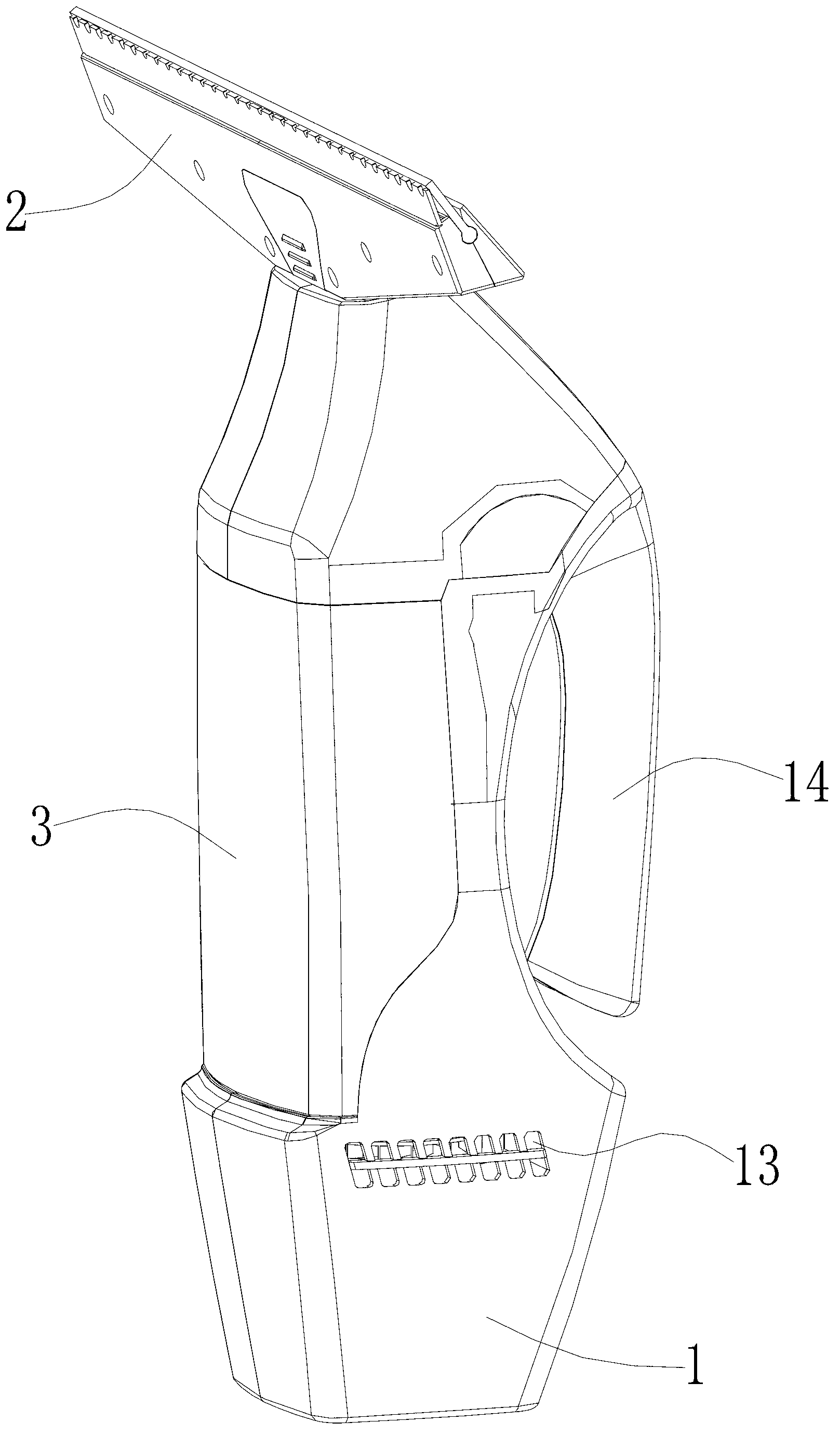

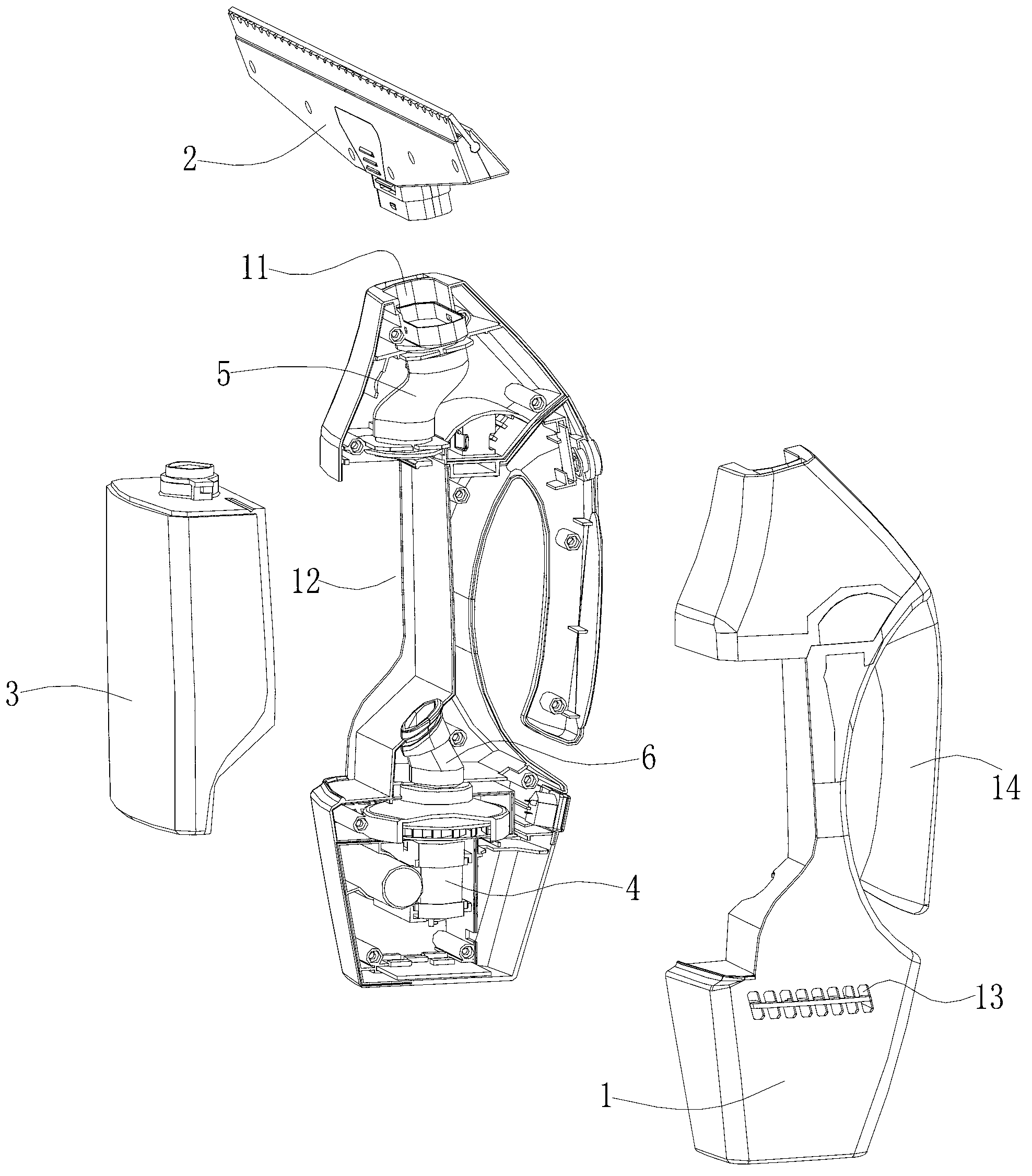

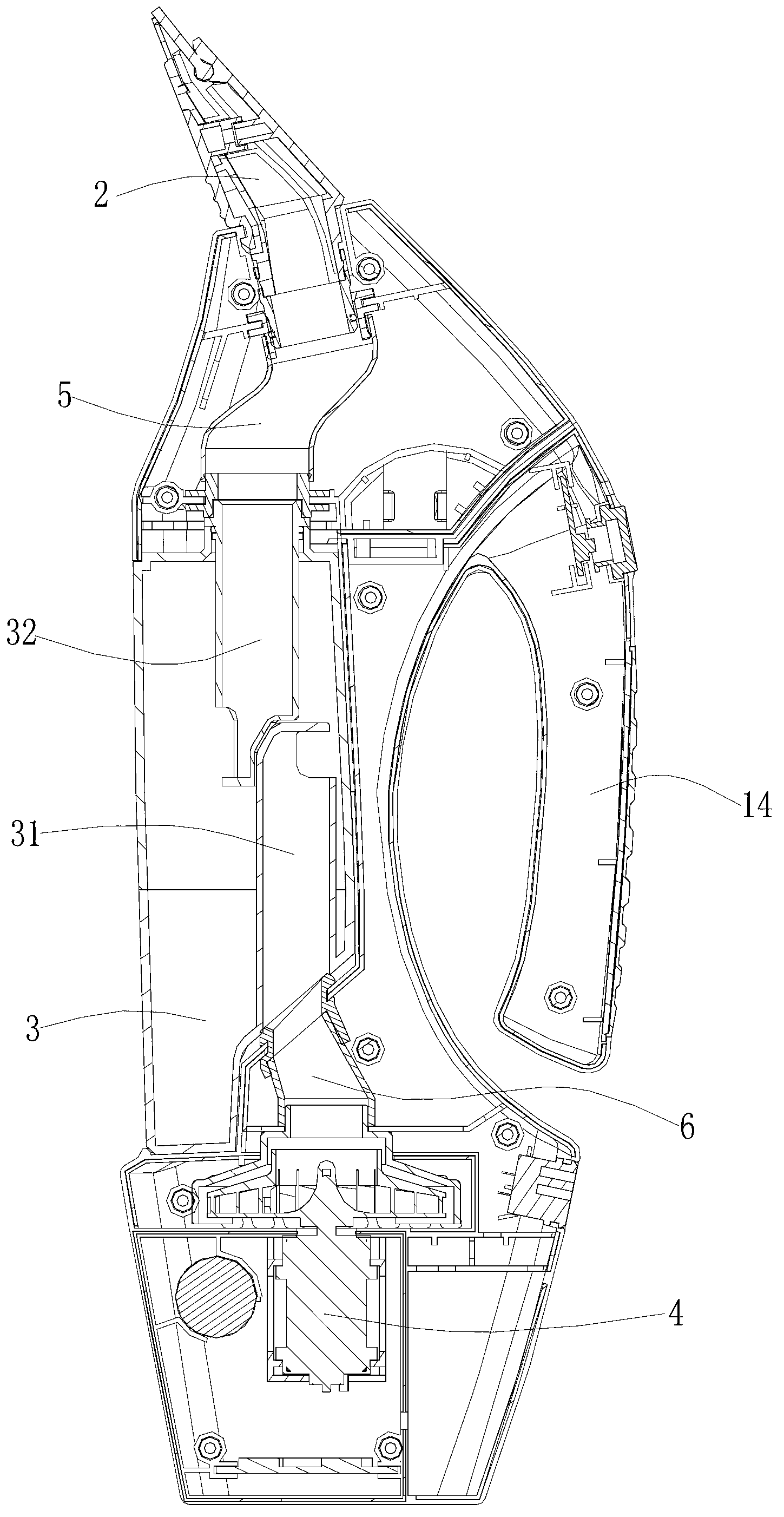

[0026] Such as Figures 1 to 4 As shown, a surface cleaning device at least includes a suction nozzle 2 , a water tank 3 , a suction unit 4 , a suction pipeline 5 , and a negative pressure pipeline 6 .

[0027] The suction nozzle 2 is used for sucking liquid and external air on the surface of the object when cleaning the surface of the object.

[0028] The water tank 3 has a cavity for collecting the sucked liquid.

[0029] The suction unit 4 is used to generate negative pressure and generate suction force.

[0030] The suction pipeline 5 is connected between the suction nozzle 2 and the water tank 3 , and is used for transporting the sucked liquid and external air into the water tank 3 .

[0031] The negative pressure pipeline 6 is connected between the suction unit 4 and the water tank 3 , and communicates with the suction pipeline 5 through the inner cavity of the water tank 3 .

[0032] The suction nozzle 2, the suction pipeline 5, the water tank 3, the negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com