Light-guiding plate and printing method thereof and backlight module

A printing method and technology of a light guide plate, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increasing printing costs and not allowing them, and achieve the effect of overcoming high printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

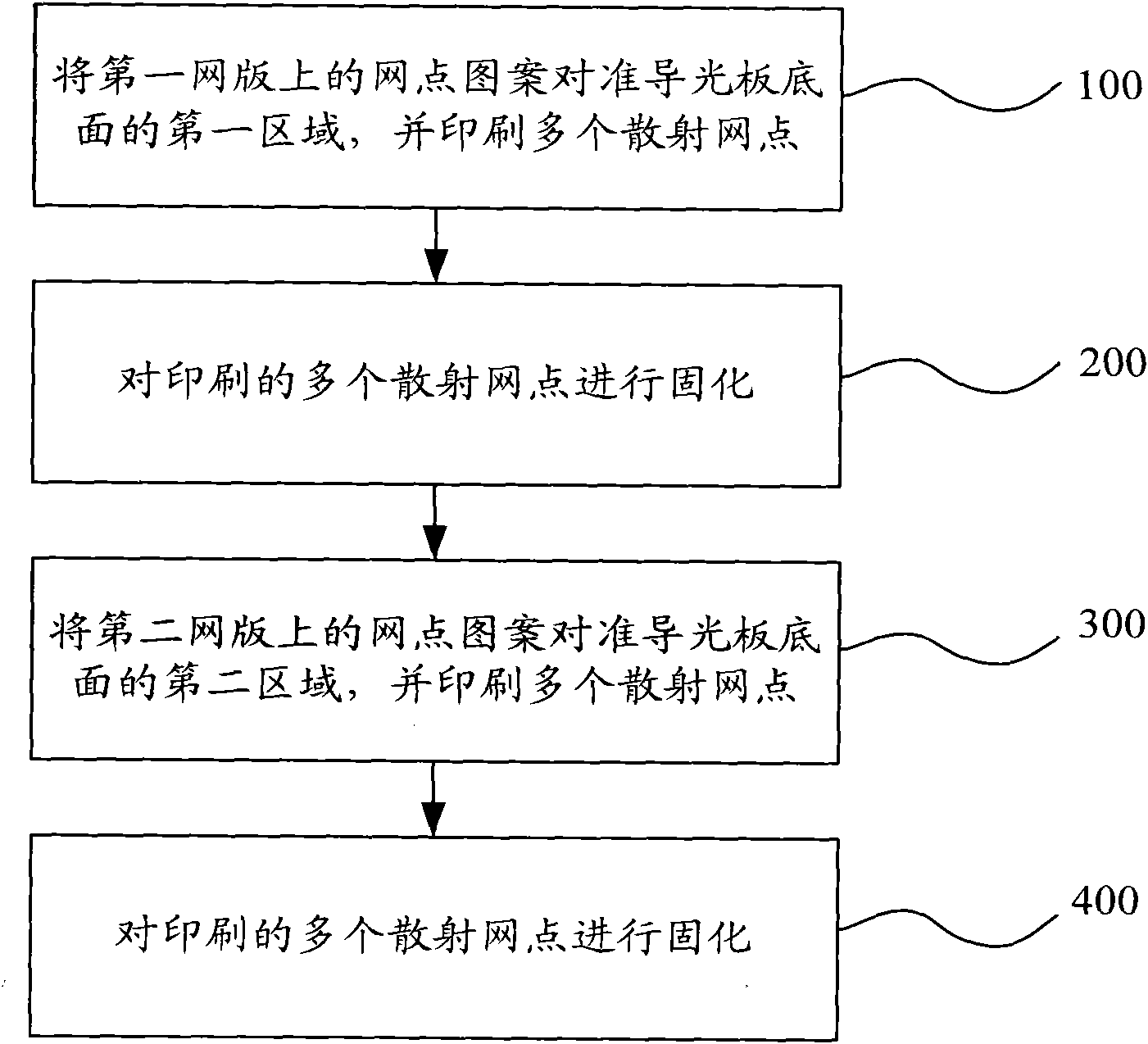

[0051] figure 2 The flow chart of the printing method of the light guide plate provided by Embodiment 1 of the present invention adopts screen printing technology, and the specific steps include:

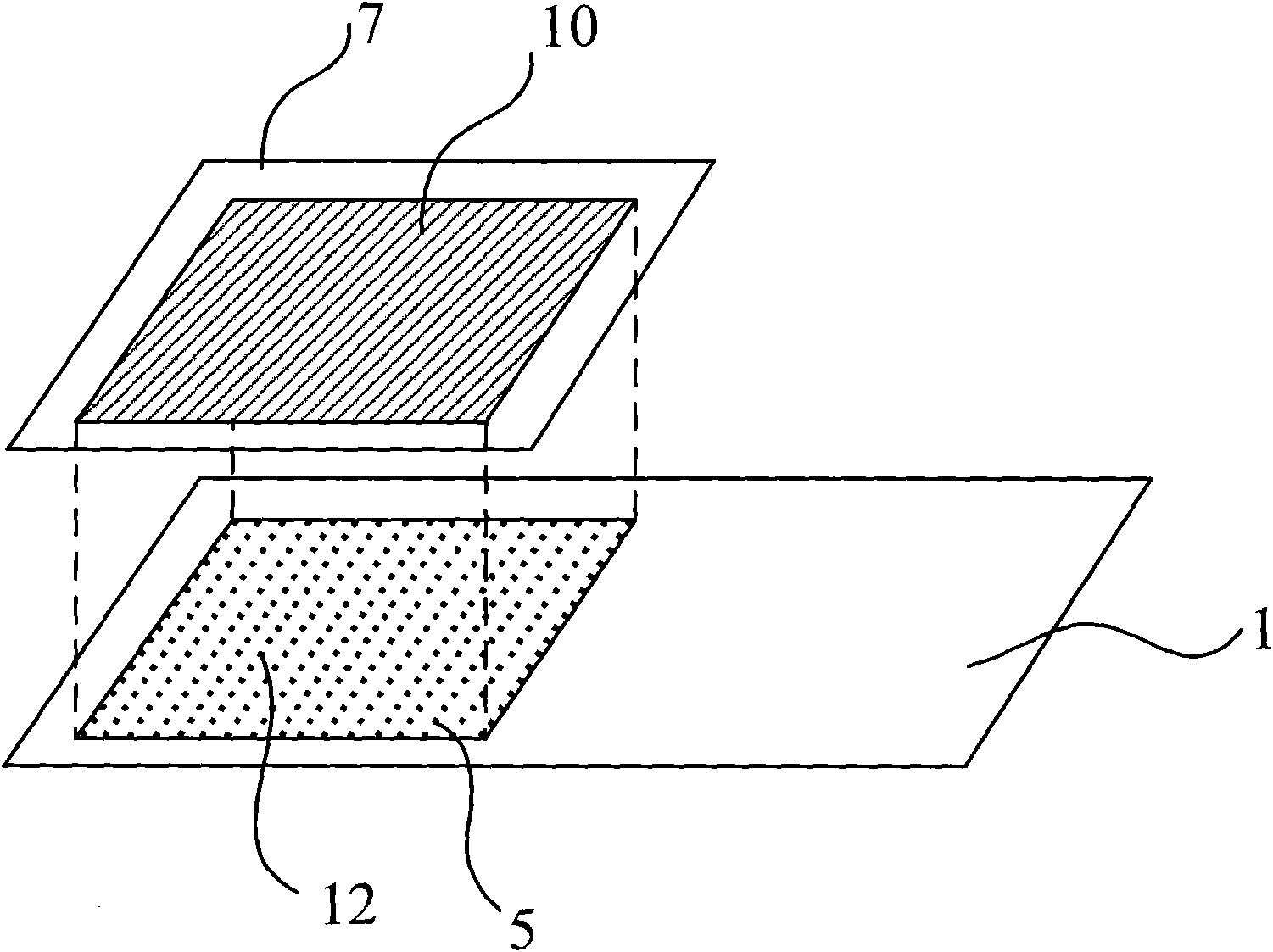

[0052] Step 100, align the dot pattern 10 on the first screen 7 with the first area 12 on the bottom surface of the light guide plate 1, and print a plurality of scattering dots 5, such as image 3 As shown, it is preferred to make the upper edge, lower edge and left edge of the dot pattern 10 parallel to the upper edge, lower edge and left edge of the light guide plate 1 and have the same distance;

[0053] Step 200, curing the printed plurality of scattering dots 5;

[0054] Step 300, align the dot pattern 10 on the second screen 8 with the second area 13 on the bottom surface of the light guide plate 1, and print a plurality of scattering dots 5 to form a stitching area 14 between the first area 12 and the second area 13 ,Such as Figure 4 As shown, it is preferable to make t...

Embodiment 2

[0065] Figure 8 The structure schematic diagram of the light guide plate provided by Embodiment 2 of the present invention, the light guide plate 1 is printed with a plurality of scattering dots 5 on the bottom surface by screen printing technology, and the function of the scattering dots 5 is that when the light hits each scattering dot 5 , the reflected light will diffuse to various angles, and then destroy the reflection condition and be evenly emitted from the light guide plate 1 . The above-mentioned light guide plate 1, by screen printing, a plurality of scattering dots 5 are respectively formed in at least the first area 12 and the second area 13 adjacent to the first area of the bottom surface of the light guide plate 1, between two adjacent areas A splice region 14 is formed, as Figure 8 As shown, the shape of the stitching area 14 is a straight line, and in specific applications, the shape of the stitching area 14 can also be a zigzag line or a circular arc line...

Embodiment 3

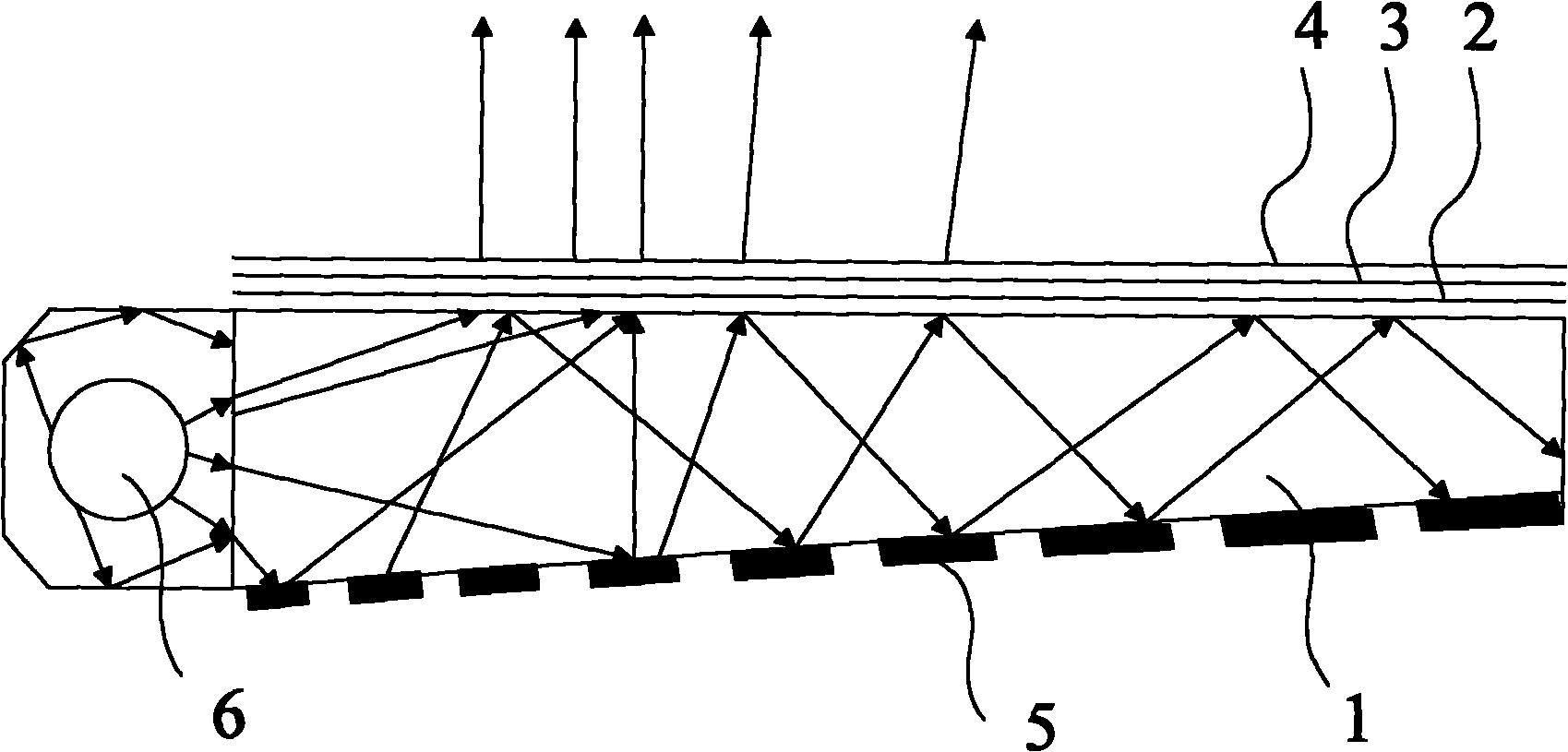

[0070] Figure 10 The structure schematic diagram of the backlight module provided by Embodiment 3 of the present invention, the backlight module of this embodiment includes: a light guide plate 1, a diffuser plate 2 arranged on the upper surface of the light guide plate 1, and a diffuser plate arranged on the upper surface of the diffuser plate 2 The prism sheet 3 , the light source 6 located on one side of the light guide plate 1 and the reflection plate 17 located on the bottom surface of the light guide plate 1 .

[0071] The bottom surface of the light guide plate 1 is printed with a plurality of scattering dots 5, and the scattering dots 5 are respectively formed in at least the first area 12 and the second area 13 adjacent to the first area on the bottom surface of the light guide plate 1, and between the two adjacent areas A stitching region 14 is formed between them. The backlight module can adopt the light guide plate 1 provided by any one of the foregoing embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com