Screen printing plate and manufacturing method thereof

A production method and screen technology, applied in printed circuit manufacturing, printing, printing machines, etc., can solve the problems of easy formation of burrs, scrapped circuit boards, and affecting effects, etc., to prevent scrapped circuit boards, simple manufacturing method, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The printing screen provided by the technical solution and its manufacturing method will be further described below in conjunction with the accompanying drawings and embodiments.

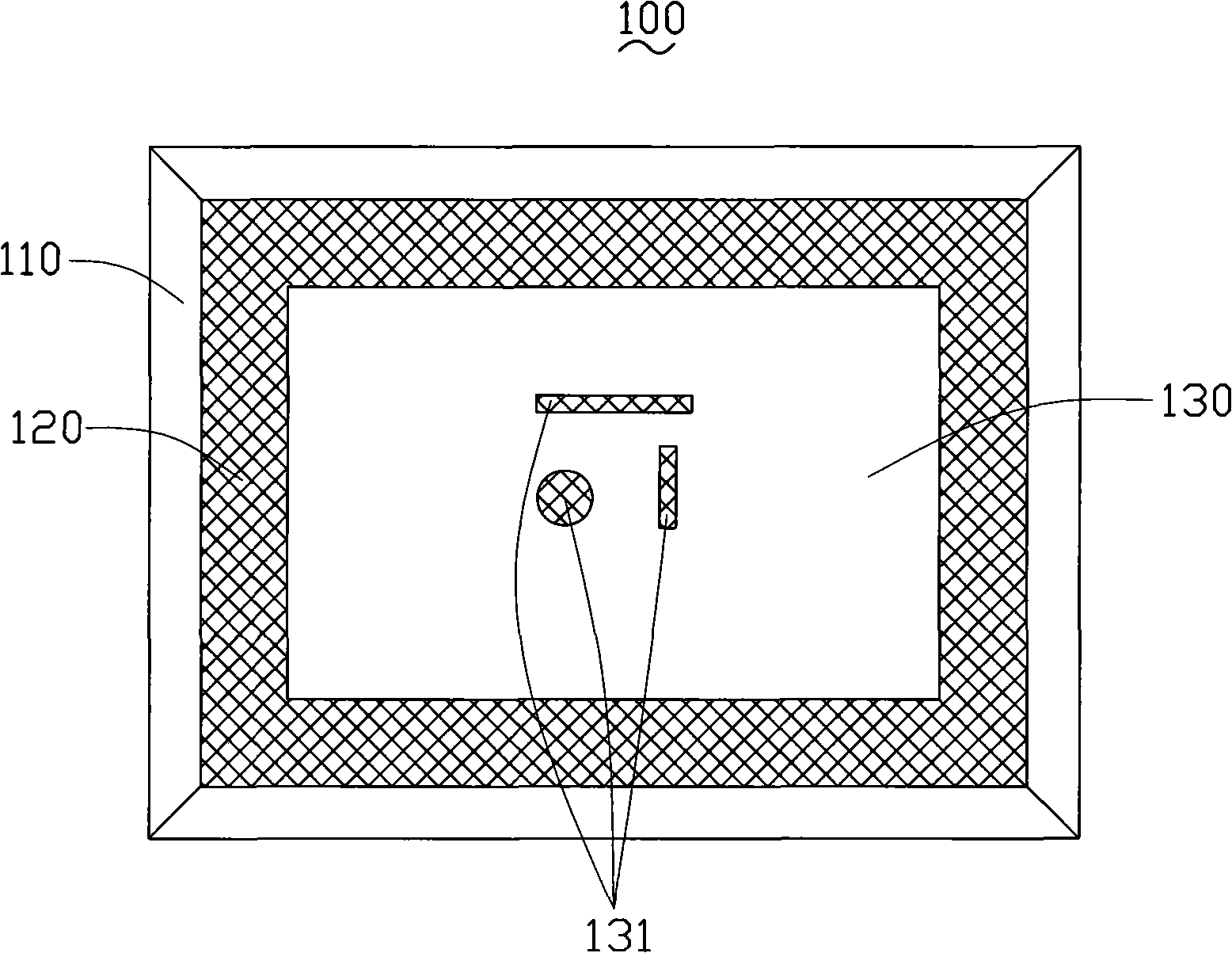

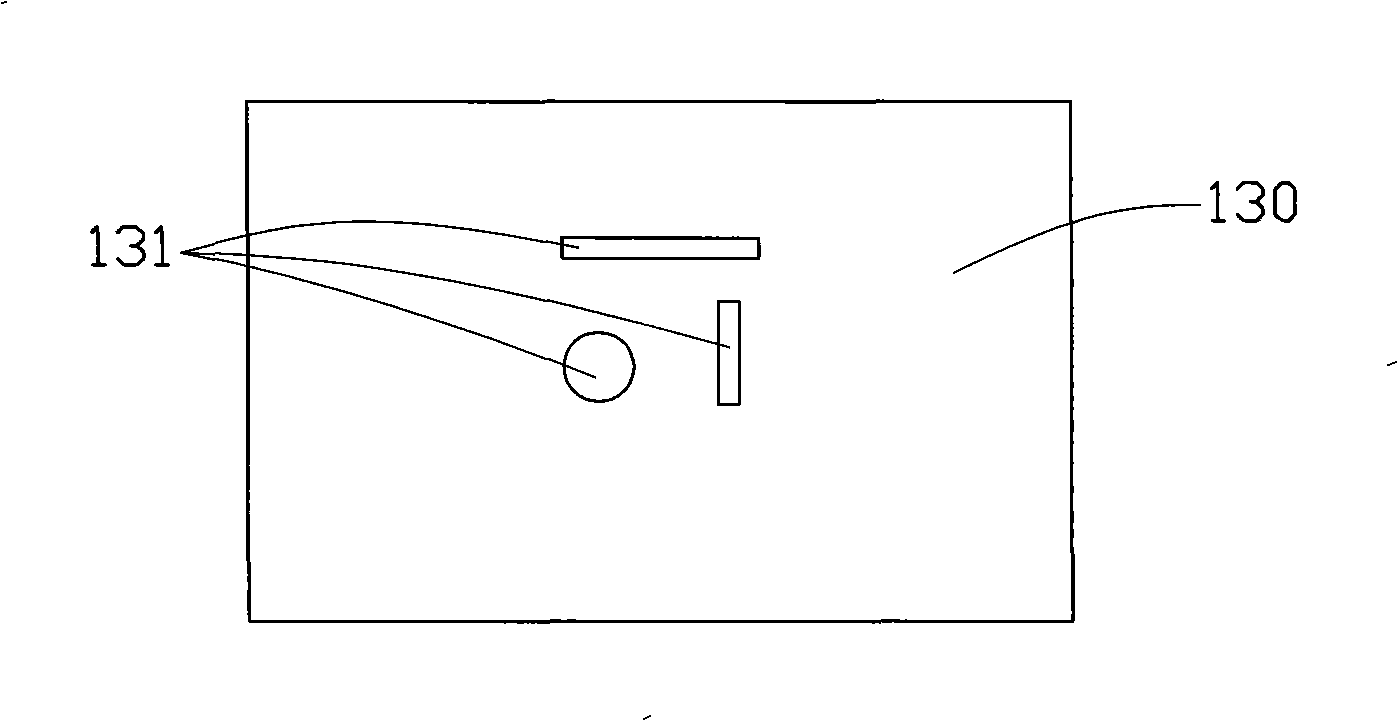

[0013] see figure 1 , the printing screen 100 provided by the embodiment of the technical solution. The printing screen 100 includes a screen frame 110 , a screen 120 and a metal sheet 130 .

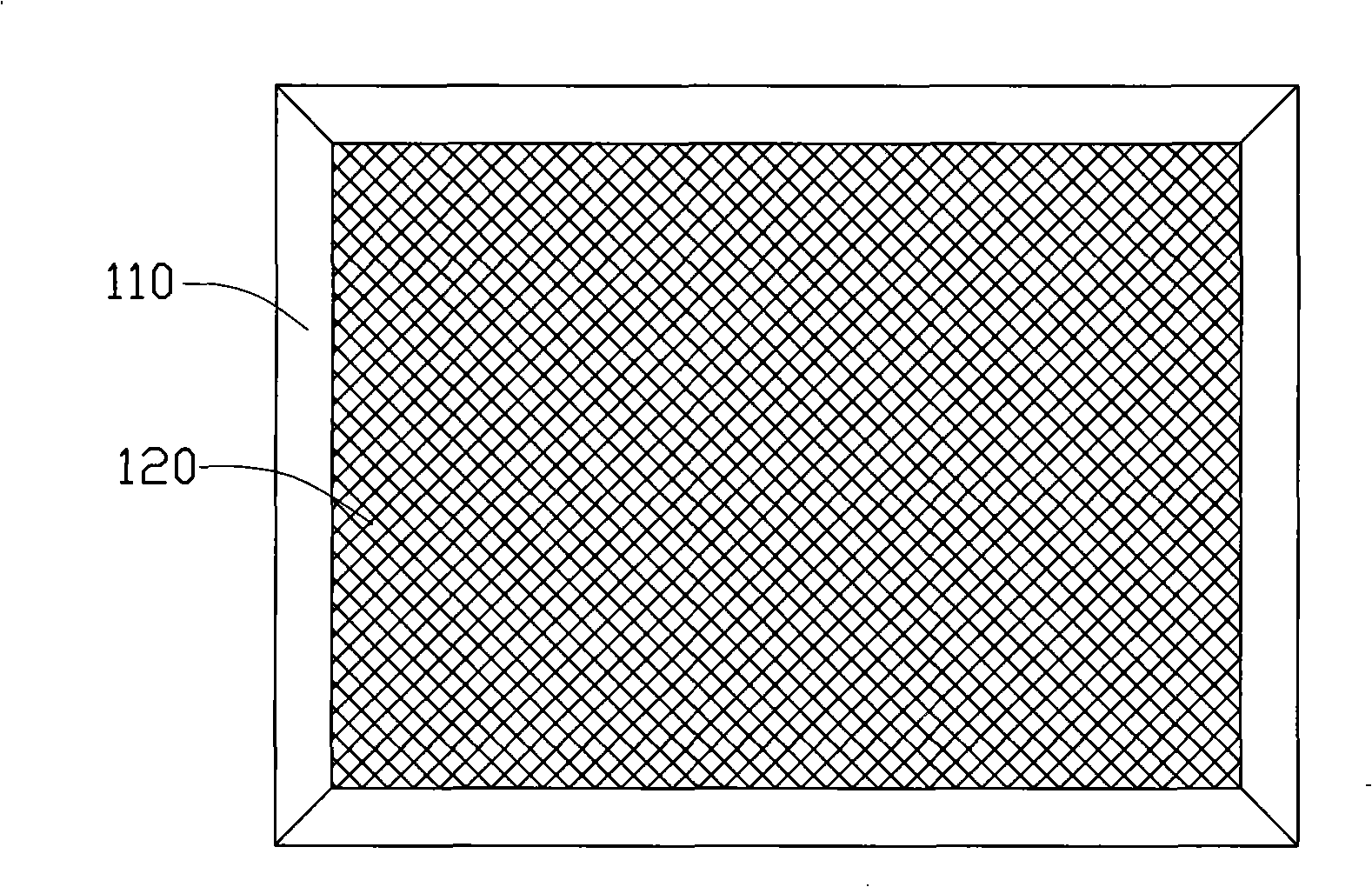

[0014] The screen frame 110 can be a metal screen frame, a wooden screen frame or a plastic screen frame. The shape of the screen frame 110 can be designed according to actual needs during use. In this embodiment, the screen frame 110 is a rectangular metal screen frame, such as an aluminum alloy screen frame.

[0015] The surrounding edges of the screen 120 are connected to the inside of the screen frame 110 , so that the screen 120 is stretched on the screen frame 110 . The screen 120 has certain elasticity and tension, which can provide the specific deformation required by the printing screen 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com