Process for making plastic surface by electroplating

A production process and plastic technology, applied in the field of plastic surface electroplating production process, can solve the problems of destroying the original characteristics of plastic components and being unable to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

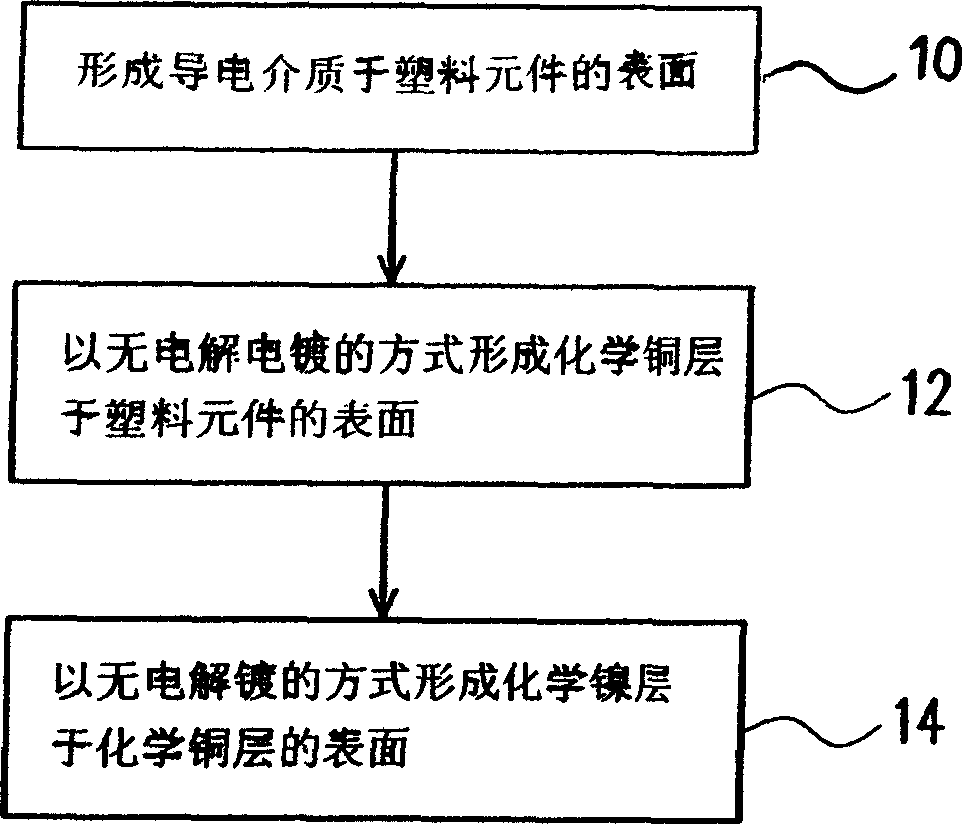

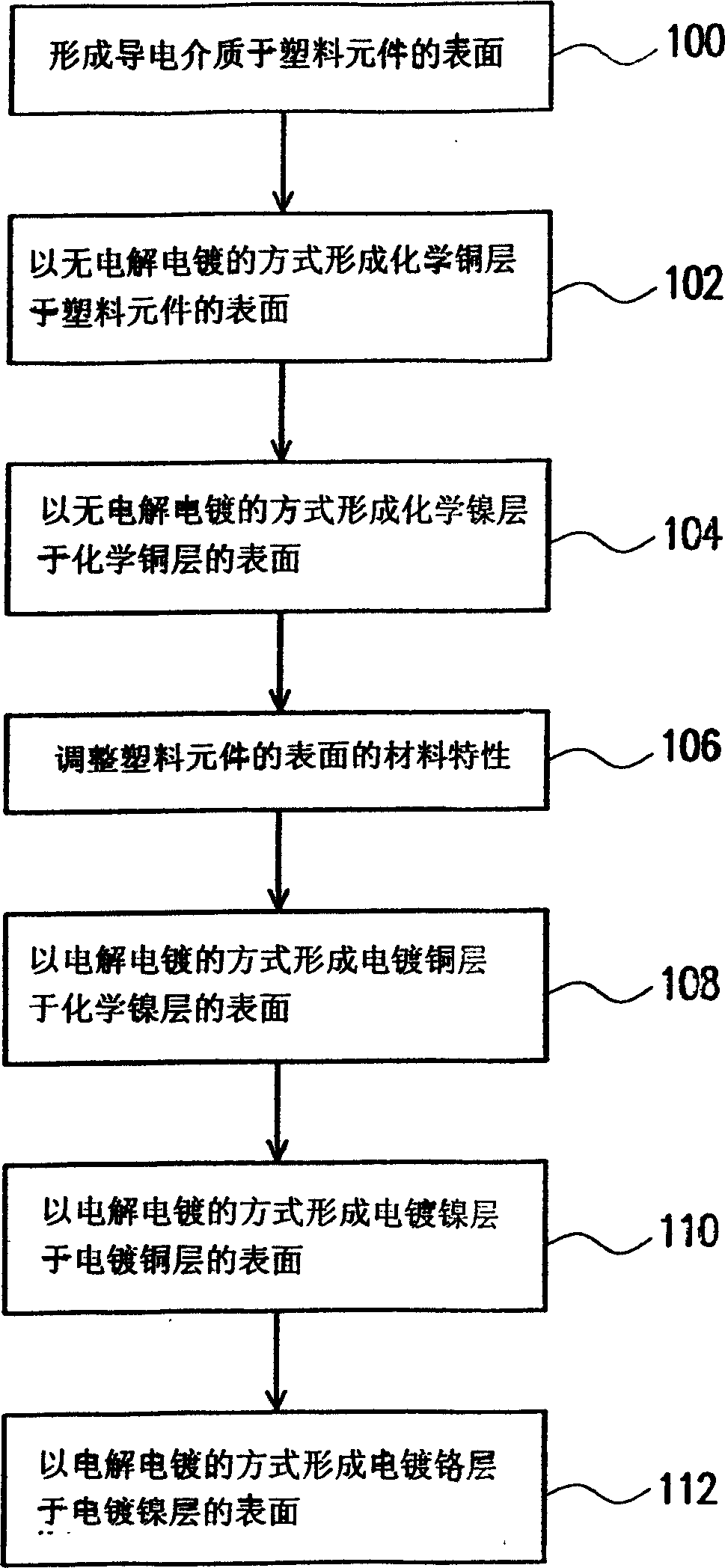

[0016] image 3 A flow chart showing a plastic surface electroplating manufacturing process according to a preferred embodiment of the present invention is shown. Please refer to image 3 As shown, the plastic surface electroplating manufacturing process of the present invention is suitable for forming a multiple metal layer on the surface of a plastic component. As shown in step 100, first form a conductive medium on the surface of the plastic component, for example, by spraying, the conductive medium is formed on the surface to be plated of the plastic component, and the conductive medium is, for example, an interface active agent, the interface activity The agent is, for example, sodium dodecyl sulfate (Sodium Dodecyl Sulfate, SDS), which is used to make the surface of the plastic material to be plated in a hydrophilic state, so that the subsequent metal particles are easy to adhere to the surface to be plated of the plastic component. Next, as shown in step 102 , an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com