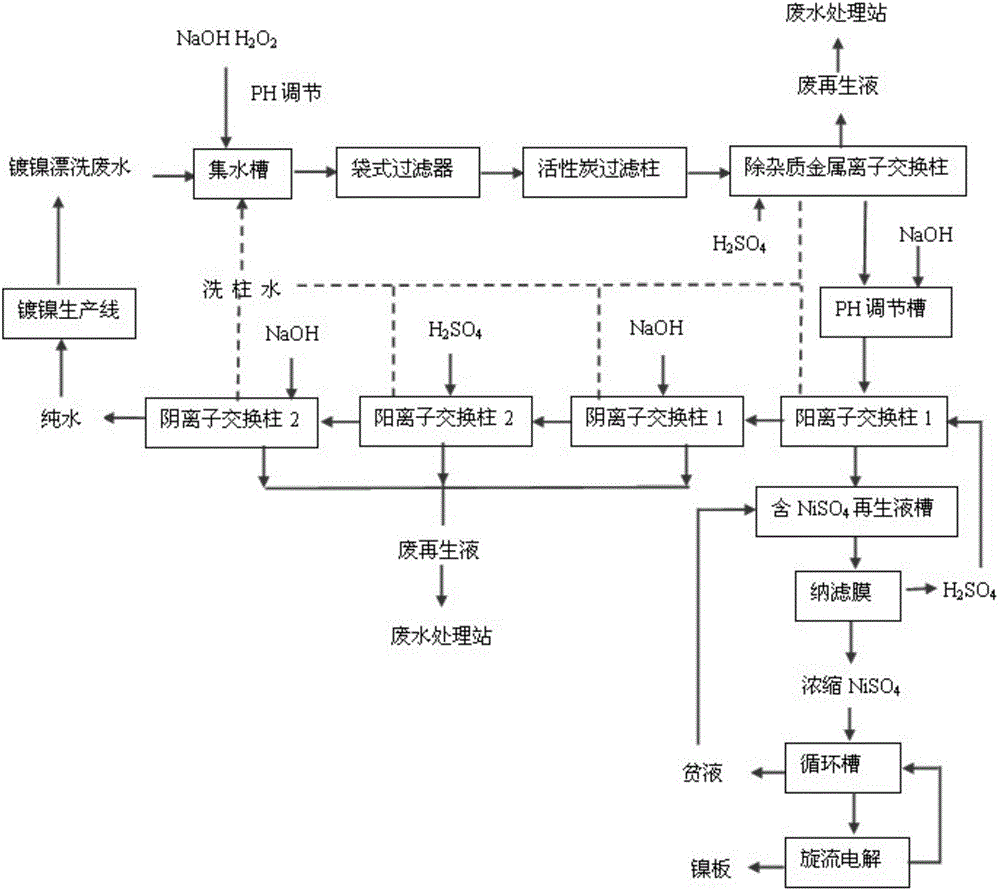

Recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater

A technology for electroplating wastewater and wastewater, which is applied in water/sewage treatment, metallurgical wastewater treatment, neutralization water/sewage treatment, etc. It can solve the problems of rising salt content in wastewater, high cost of nickel recovery, and accumulation of bath solution, etc., to reduce Wastewater treatment cost, wide range of use, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] Take an electroplating factory as an example: a large electroplating enterprise produces a total of about 150 cubic meters of acidic nickel plating wastewater every day.

[0033] The composition of wastewater is as follows:

[0034] ;

[0035] Note: The running time is calculated on the basis of 20 hours / day

[0036] Process index requirements:

[0037] Recycled water: water volume≧90m 3 / d Conductivity≦50µs / cm.

[0038] Metallic nickel: production≧40kg / d, electrolytic nickel purity≧99.9%, nickel recovery≧90%

[0039] The specific processing steps are as follows:

[0040] Step (1): Use 50g / L of H 2 SO 4 Solution, adjust the pH of the nickel-plating rinse wastewater to 2-3, add 30% hydrogen peroxide, control the pH of the wastewater at 2-2.3, and remove the Fe in the wastewater 2+ All Fe 3+ , to facilitate the subsequent removal of iron from wastewater;

[0041]Step (2): Wastewater is filtered through bag filters and activated carbon columns to remove solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com