Method for preparing nano carbon fiber

A nano carbon fiber, carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of inferior fiber quality, and achieve the effects of low equipment cost, simple preparation method and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

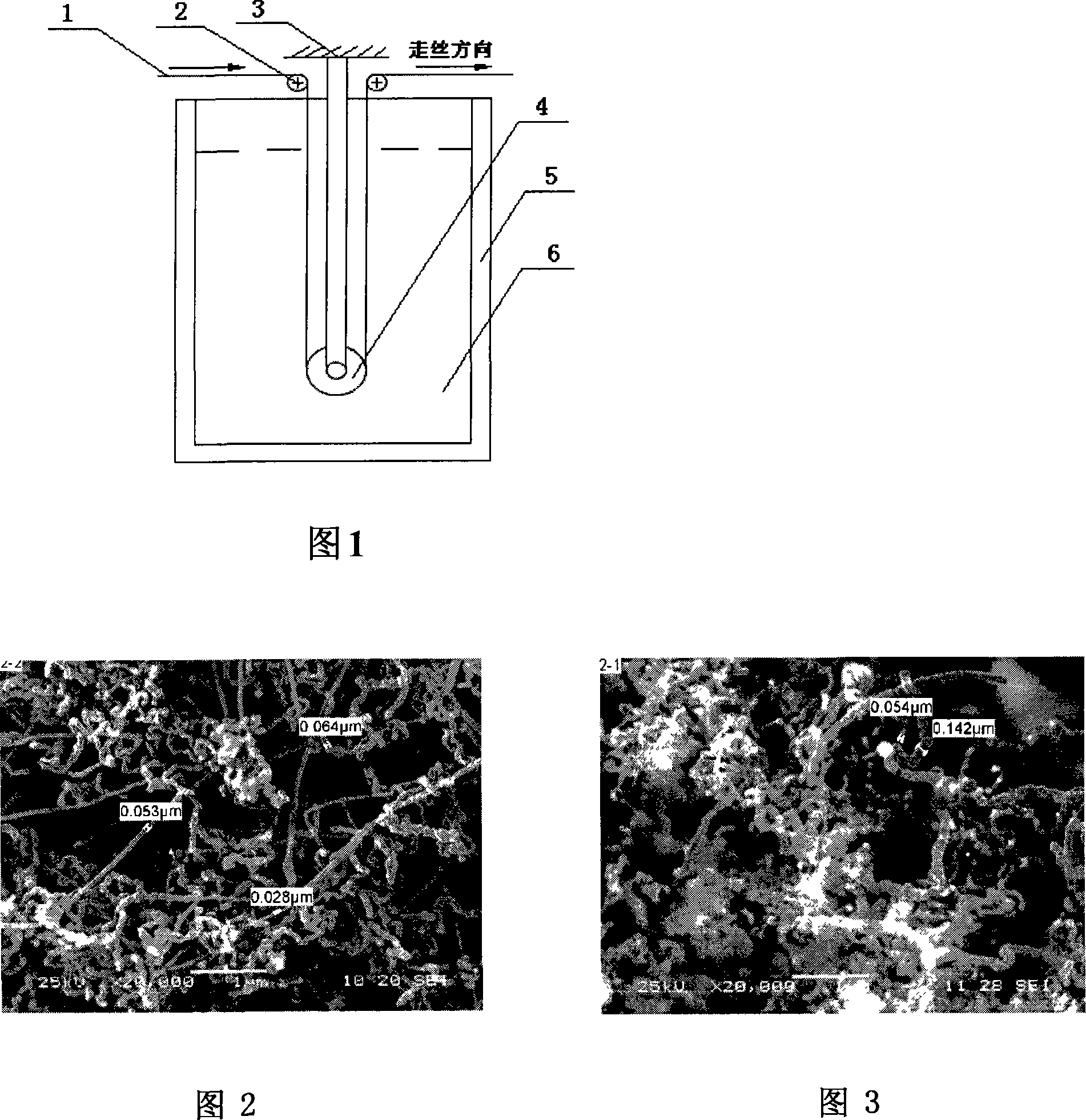

Embodiment 1

[0031] Soak the 1K HTA carbon fiber produced by Japan's Toray Company in acetone solution for 4 hours to remove the glue on the surface of the fiber. Dry in the oven for 5 hours at 70°C. A nickel sulfate solution with a concentration of 10% was prepared as the electroplating solution, the current intensity was 15mA, and the wire speed was 40cm / min for nickel electroplating. The nickel-plated carbon fibers were cleaned twice by ultrasonic waves for 2 minutes each, and then dried at 40°C for 5 hours. After taking it out, install it with the workpiece and place it in a chemical vapor deposition furnace for vapor phase growth of carbon nanofibers. Vacuumize the inside of the reaction furnace, and when the pressure is less than 50Pa, start energizing to raise the temperature. The heating time from room temperature to the final reaction temperature of 1000°C is 95 minutes. When the temperature rises to 1000°C, keep it warm for 25 minutes, then start to fill with gas, of which the ...

Embodiment 2

[0033] Soak the 3K T-300 carbon fiber produced by Japan Toray Company in benzene solution for 3 hours to remove the glue on the surface of the fiber. The mass ratio of carbon fiber and organic solution is 1:10, and then use ultrasonic cleaning for 4 times. Dry in a drying oven for 4 hours at 60 °C. A nickel sulfate solution with a concentration of 5% was prepared as the electroplating solution, the current intensity was 10mA, and the wire speed was 20cm / min for nickel electroplating. The nickel-plated carbon fibers were cleaned twice with ultrasonic waves for 1 min. Then, it was dried at 30° C. for 6 hours. After taking it out, install it with the workpiece and place it in a chemical vapor deposition furnace for vapor phase growth of carbon nanofibers. Vacuumize the inside of the reaction furnace, and when the pressure is less than 50Pa, start energizing to raise the temperature. The heating time from room temperature to the final reaction temperature of 800°C is 85 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com