Process method for reducing magnetic loss of neodymium-iron-boron permanent magnet under high-temperature and high-humidity conditions

A high-temperature, high-humidity, process method technology is applied in the field of reducing the magnetic loss of NdFeB permanent magnets under high-temperature and high-humidity conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

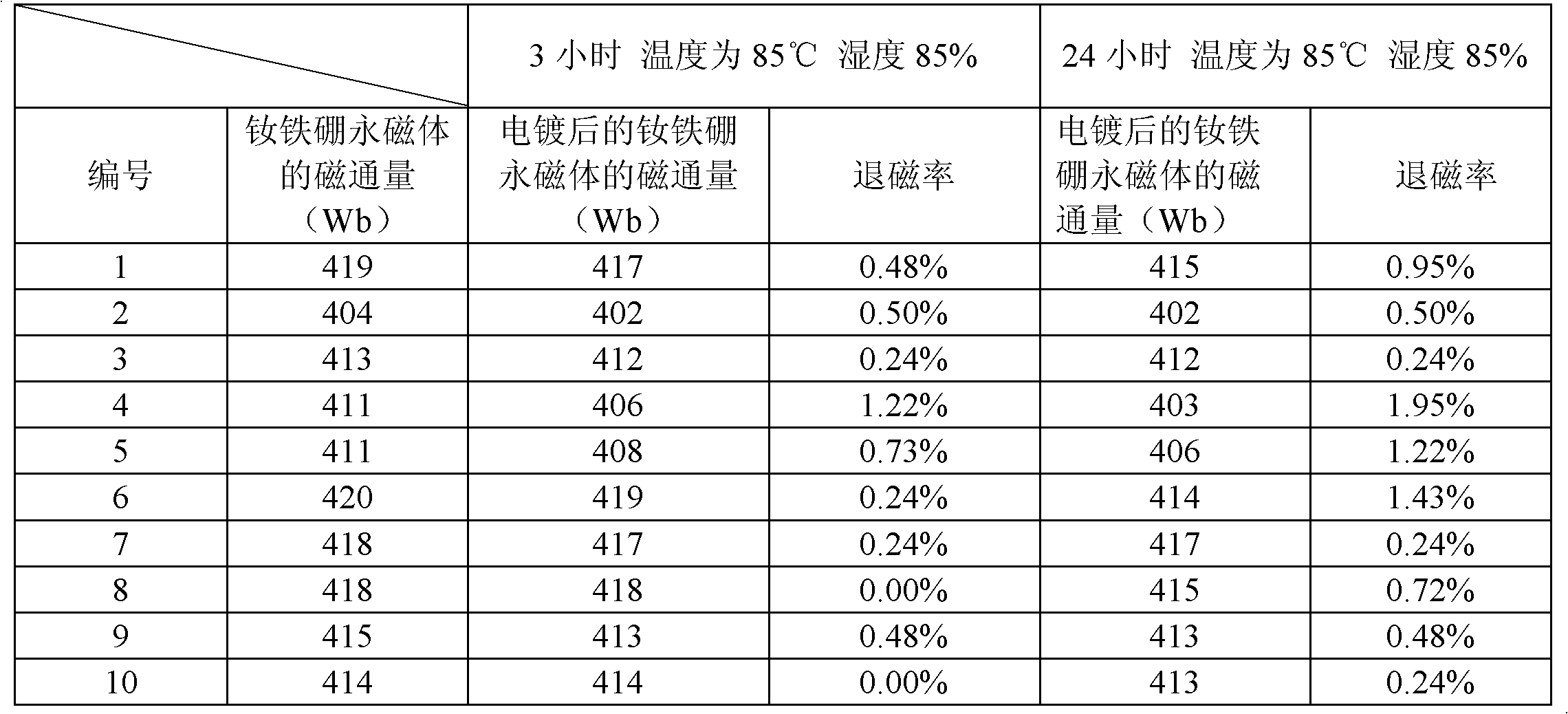

Embodiment 1

[0016] For a piece of NdFeB permanent magnet, it is required to have a magnetic loss of ≤10% after 24 hours of high temperature and high humidity test after electroplating NiCuNi. The specific process method is as follows:

[0017] 1. Take 3kg of the product of this specification and use anhydrous dry chamfering in a flat-bottomed vibrating finishing machine. The abrasive is a spherical type with a diameter of Φ3, the weight is 25kg, the chamfering time is 3 hours, and the vibration frequency is 40r / min.

[0018] 2. Use ultrasonic waves to degrease in a neutral degreasing solution with a temperature controlled at 60°C for 2 minutes, and wash with flowing water to remove the degreasing liquid on the surface of the product.

[0019] 3. Use 1% HNO 3 The solution is pickled for 20 seconds, and ultrasonic cleaning is performed immediately after each 5 seconds, and the residual acid solution in the blind hole of the sintered NdFeB permanent magnet is removed by using the ultrasonic...

Embodiment 2

[0026] For a piece of NdFeB permanent magnet, it is required to have a magnetic loss of ≤10% after 24 hours of high temperature and high humidity test after electroplating NiCuNi. The specific process method is as follows:

[0027] 1. Take 3kg of the product of this specification and use anhydrous dry chamfering in a flat-bottomed vibrating finishing machine. The abrasive is a ball type with a diameter of Φ3, the weight is 25kg, the chamfering time is 3 hours, and the vibration frequency is 40r / min.

[0028] 2. Use ultrasonic waves to degrease in a neutral degreasing solution with a temperature controlled at 60°C for 2 minutes, and wash with flowing water to remove the degreasing liquid on the surface of the product.

[0029] 3. Use 1% HNO 3 The solution is pickled for 20 seconds, and ultrasonic cleaning is performed immediately after each 5 seconds, and the residual acid solution in the blind hole of the sintered NdFeB permanent magnet is removed by using the ultrasonic cavi...

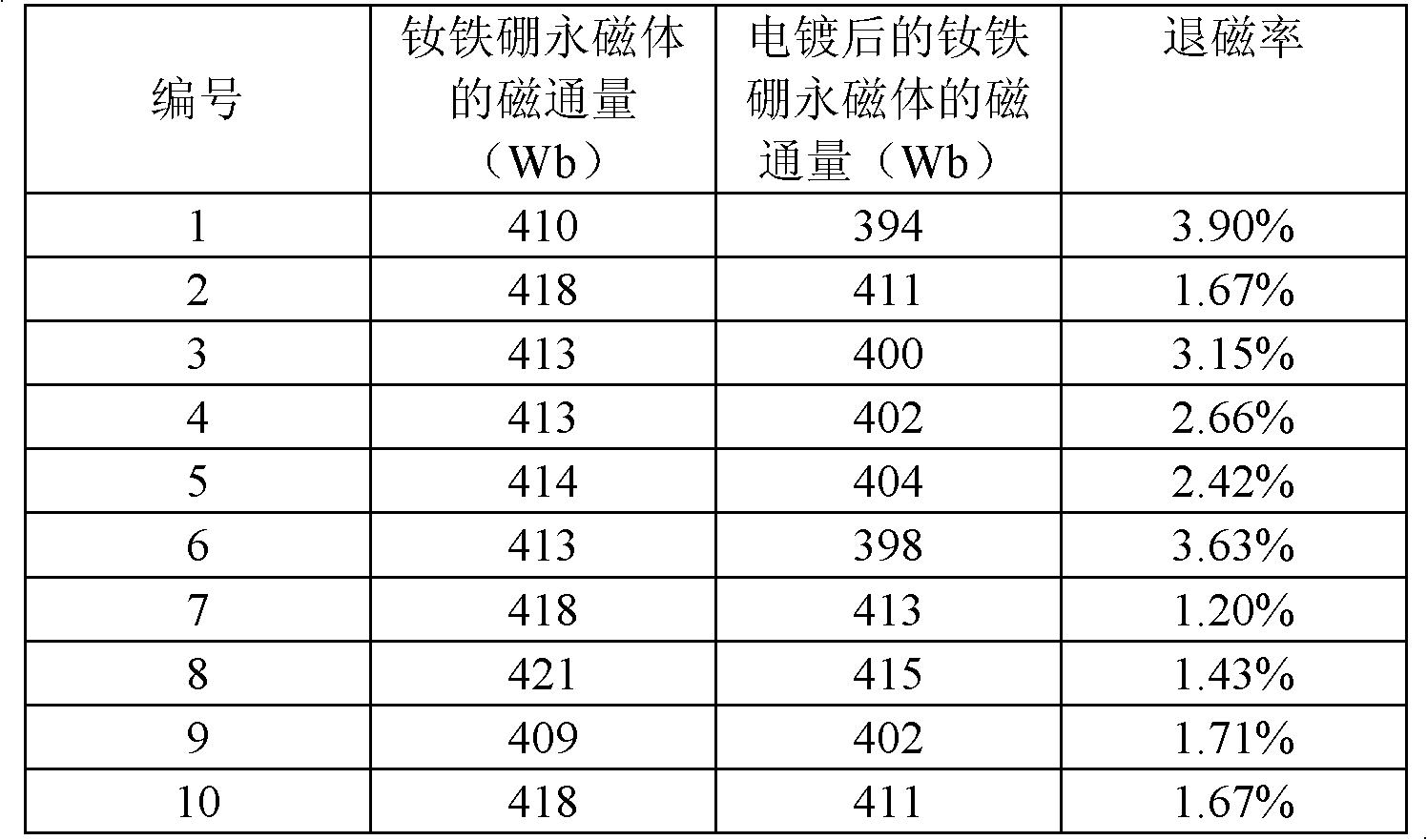

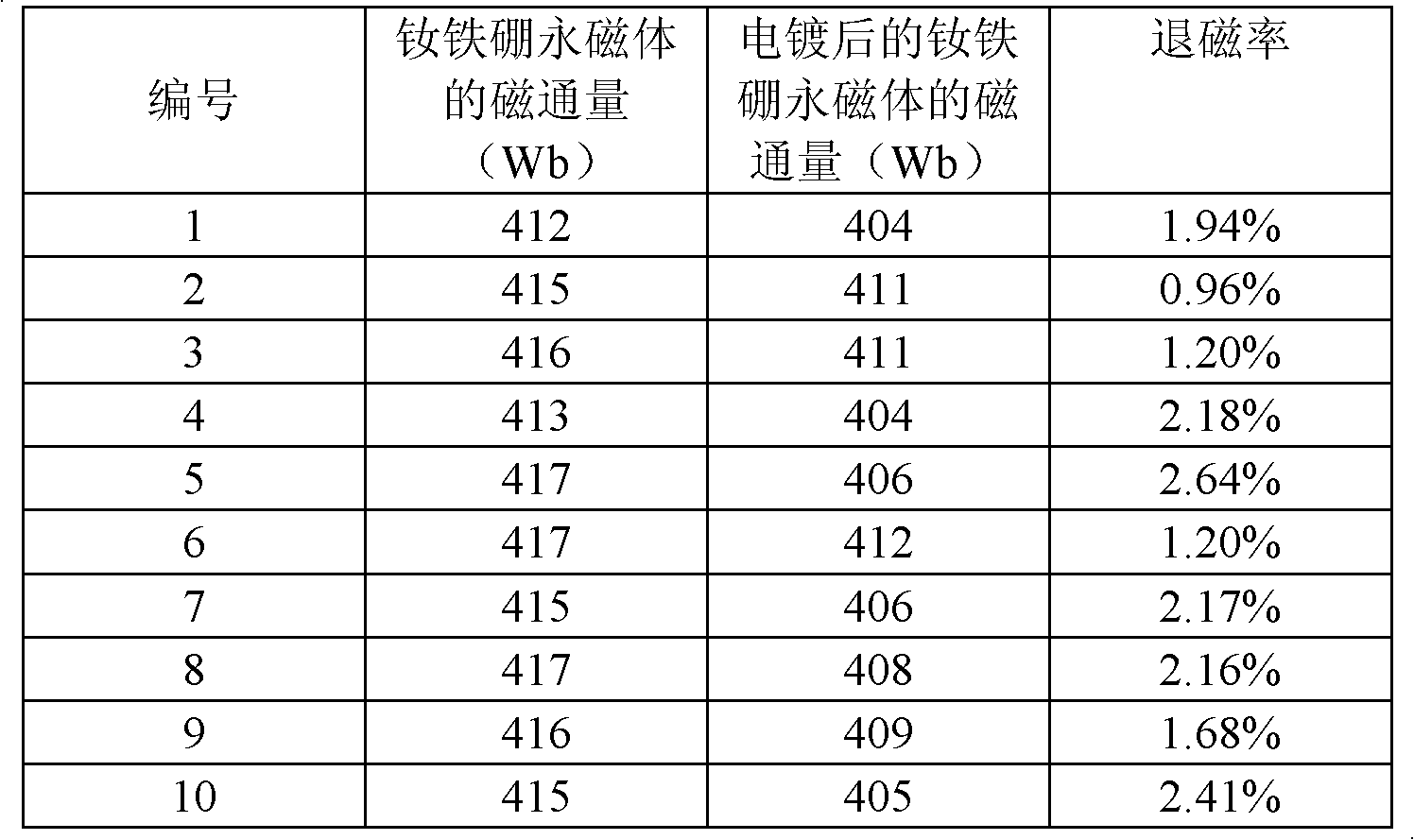

Embodiment 3

[0039] For a piece of NdFeB permanent magnet, it is required to have a magnetic loss of ≤10% after 24 hours of high temperature and high humidity test after electroplating NiCuNi. The specific process method is as follows:

[0040] 1. Take 3kg of the product of this specification and use anhydrous dry chamfering in a flat-bottomed vibrating finishing machine. The abrasive is a ball type with a diameter of Φ3, the weight is 25kg, the chamfering time is 3 hours, and the vibration frequency is 40r / min.

[0041] 2. Use ultrasonic waves to degrease in a neutral degreasing solution with a temperature controlled at 60°C for 2 minutes, and wash with flowing water to remove the degreasing liquid on the surface of the product.

[0042] 3. Use 1% HNO 3 The solution is pickled for 20 seconds, and ultrasonic cleaning is performed immediately after each 5 seconds, and the residual acid solution in the blind hole of the sintered NdFeB permanent magnet is removed by using the ultrasonic cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com