Application process of multi-layer electroplated coinage materials and products thereof

A multi-layer electroplating and coinage technology, applied in the field of coinage, can solve problems such as poor corrosion resistance of nickel-iron alloys, and achieve the effects of good process performance, poor corrosion resistance and lower coinage costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

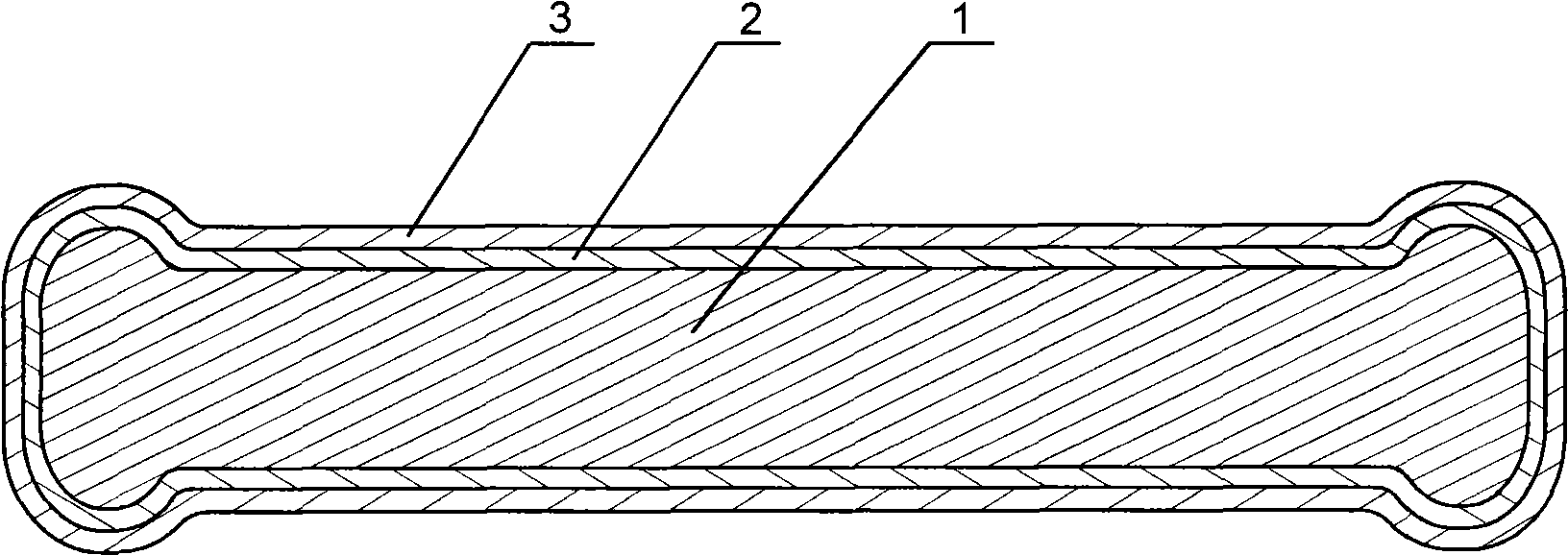

Embodiment 1

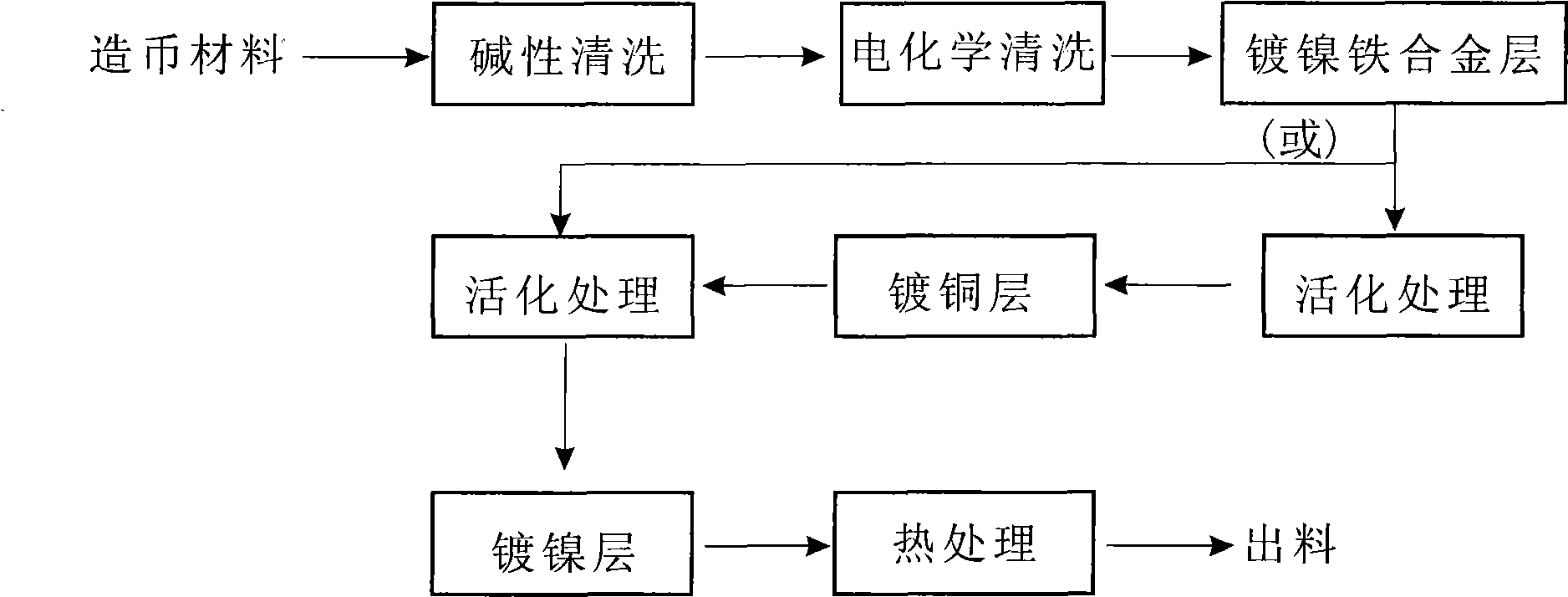

[0061] Electroplating nickel-iron alloy layer and nickel layer on the coinage material (metal cake-shaped material) is specifically carried out according to the following steps:

[0062] (1), Electroplated nickel-iron alloy bottom layer

[0063] a. Alkaline washing

[0064] Put the metal cake-shaped material into the alkaline cleaning tank, the alkaline cleaning solution is prepared with 48g / L alkaline cleaning agent, the pH value is 12, the temperature is 65°C, and the drum speed is 7r / min for 1 minute cleaning, and then use Rinse with ionized water. Alkaline cleaning agent consists of sodium hydroxide: 41.8%, sodium carbonate: 25.0%, sodium gluconate: 2.2%, nonylphenol 1.8%, sodium silicate 9.2%, sodium triphosphate 9.2%, EDTA9.0%, twelve Sodium Alkylbenzene Sulfate 1.8% Composition.

[0065] The oil stains on the above-mentioned cake-shaped materials can be preliminarily removed by alkaline cleaning. Alkaline cleaning includes the chemical degreasing process of saponific...

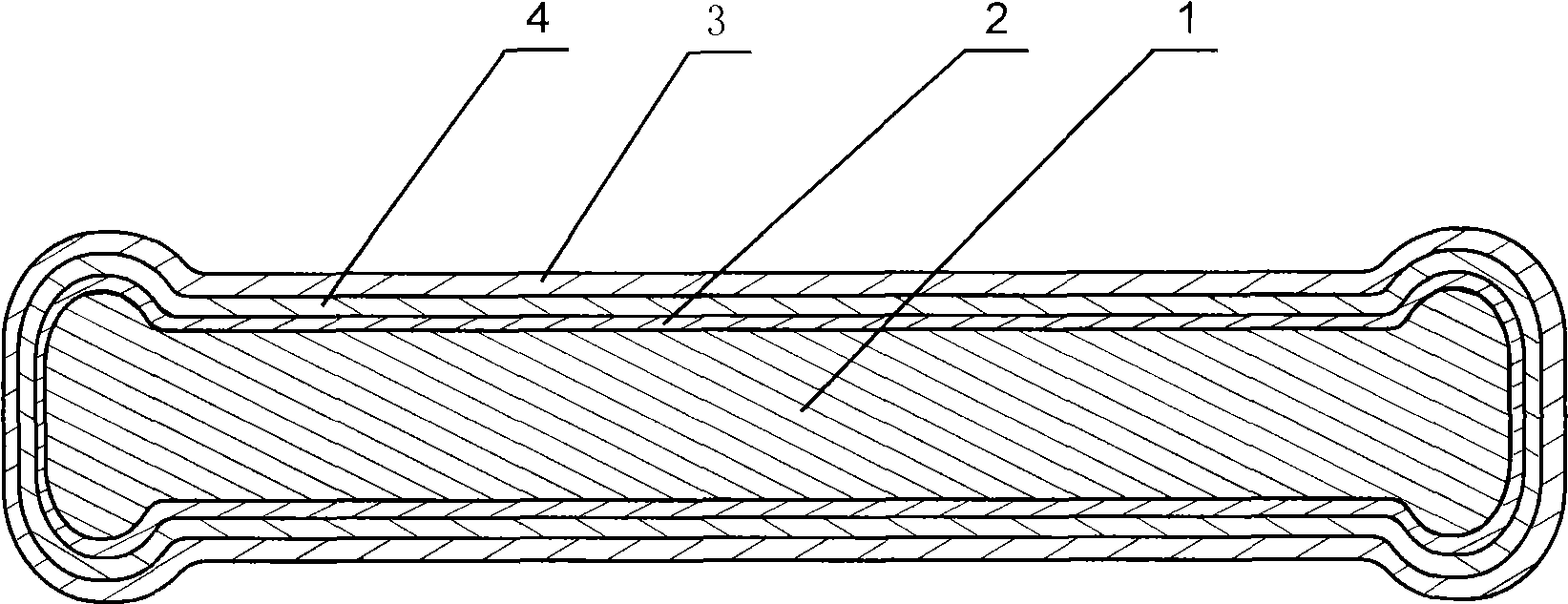

Embodiment 2

[0082] Electroplate nickel-iron alloy layer, copper layer and nickel layer respectively successively on coinage material (metal cake shape material), and its specific electroplating process is carried out according to the following steps:

[0083] (1), Electroplated nickel-iron alloy bottom layer

[0084] a. Alkaline washing

[0085] Put the metal cake-shaped material into the alkaline cleaning tank, the alkaline cleaning solution is prepared with 55g / L alkaline cleaning agent, the pH value is 12, the temperature is 60°C, and the drum speed is 8r / min for 2 minutes, and then use Rinse with ionized water. Alkaline cleaning agent consists of sodium hydroxide: 43.5%, sodium carbonate: 28.0%, sodium gluconate: 3.0%, nonylphenol 2.2%, sodium silicate 10.0%, sodium triphosphate 10.0%, EDTA9.5%, twelve Sodium Alkylbenzene Sulfate 2.0% composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com