A kind of micro-expanding oil well cement

An oil well cement and micro-expansion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor expansion effect, slow expansion speed, and inconspicuous expansion of expansion cement, so as to improve corrosion resistance, Improved early strength and good swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

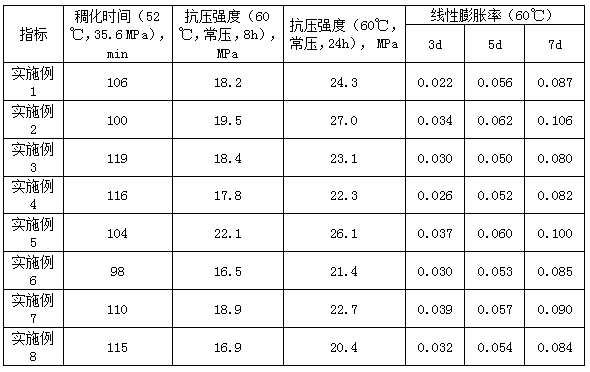

Examples

Embodiment 1

[0031] A micro-expansion oil well cement, comprising the following raw materials in parts by weight: 50 parts of gel material; 30 parts of active material; 0.5 part of magnesium oxide expansion agent; 0.1 part of alkaline activator; 2 parts of stabilizing material;

Embodiment 2

[0033] A micro-expansion oil well cement, comprising the following raw materials in parts by weight: 80 parts of gel material; 20 parts of active material; 3 parts of magnesium oxide expansion agent; 8 parts of alkaline activator; 5 parts of stabilizing material;

[0034] In the above formula, the magnesium oxide expansion agent is light-burned magnesium oxide powder.

Embodiment 3

[0036]A micro-expansion oil well cement, comprising the following raw materials in parts by weight: 60 parts of gel material; 40 parts of active material; 2 parts of magnesium oxide expansion agent; 5 parts of alkaline activator; 3 parts of stabilizing material;

[0037] In this embodiment, the magnesium oxide expansion agent is light-burned magnesium oxide powder with a magnesium oxide content > 80% and an activity > 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com