Modified graphene oxide co-cured waterborne epoxy resin coating and preparation method thereof

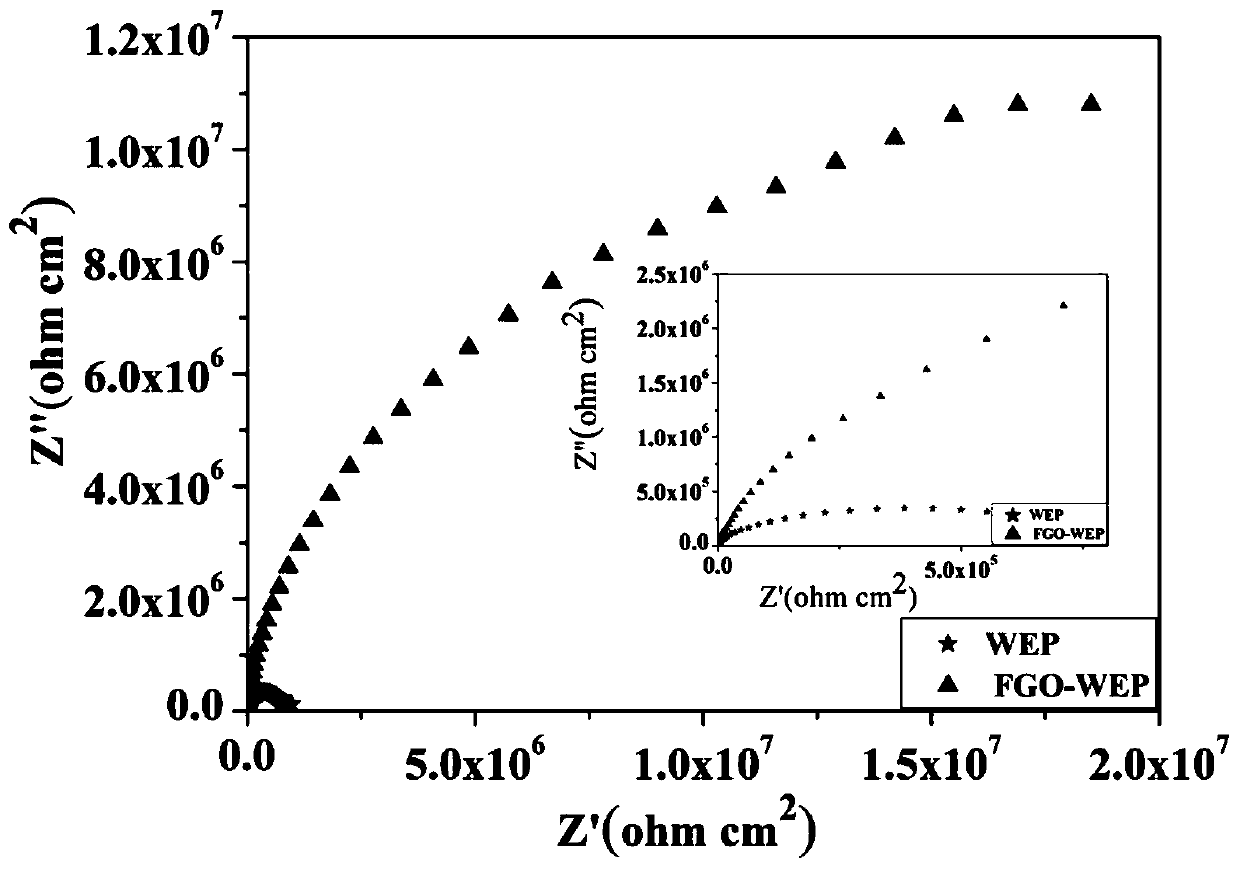

A technology of water-based epoxy resin and oxide stone, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of poor corrosion resistance and poor film-forming performance, achieve excellent performance, improve corrosion resistance, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In terms of parts by mass, take 0.1 parts of graphene oxide powder and disperse it in 100 parts of absolute ethanol, then add 2 parts of silane coupling agent γ-methacryloxypropyl trimethoxysilane into the reaction kettle and heat up to 60 ℃, reacted for 7 hours, after the reaction was completed, it was lowered to room temperature and washed 3 times with deionized water, then 400 parts of deionized water was added, and 10 parts of allyl trimethyl ammonium chloride was added as a modifier and the reaction kettle was heated up to React at 70°C for 4 hours, cool down to room temperature after the reaction is completed, filter and wash with deionized water for 5 times, then dry into powder to obtain modified graphene oxide powder;

[0043] 2) In terms of parts by mass, 0.006 parts of the co-curing agent modified graphene oxide powder obtained in step 1) are dispersed into 4 parts of deionized water, and 2.5 parts of water-based epoxy resin curing agent Us-700 are taken, and ...

Embodiment 2

[0047] 1) In terms of parts by mass, take 0.5 parts of graphene oxide powder and disperse it in 350 parts of absolute ethanol, then add 5 parts of silane coupling agent vinyl tris(b-methoxyethoxy)silane and put it into the reaction kettle to raise the temperature to 100°C, react for 9 hours, after the reaction is completed, cool down to room temperature and wash with deionized water for 3 times, then add 600 parts of deionized water, and then add 20 parts of (3-acrylamidopropyl) trimethyl ammonium chloride for modification Put the reagents together into the reactor and raise the temperature to 100°C for 8 hours to react. After the reaction is completed, cool down to room temperature, filter and wash with deionized water for 3 times, and then dry it into powder to obtain modified graphene oxide powder;

[0048] 2) In terms of parts by mass, 0.036 parts of the co-curing agent modified graphene oxide powder obtained in step 1) are dispersed into 8 parts of deionized water, and 5 p...

Embodiment 3

[0052] 1) In terms of parts by mass, take 0.8 parts of graphene oxide powder and disperse it in 500 parts of absolute ethanol, then add 8 parts of silane coupling agent vinyltriethoxysilane into the reactor and raise the temperature to 120°C, and react for 11 hours After the reaction is completed, it is lowered to room temperature and washed with deionized water for 5 times, then 750 parts of deionized water is added, and 35 parts of methacryloyloxyethyltrimethylammonium chloride is added as a modifier and the temperature is raised to 120 ℃ for 9 hours, after the reaction was completed, the reaction was lowered to room temperature, filtered and washed with deionized water for 4 times, and then dried into powder to obtain modified graphene oxide powder;

[0053] 2) In terms of parts by mass, 0.06 parts of the co-curing agent modified graphene oxide powder obtained in step 1) are dispersed into 16 parts of deionized water, and 10 parts of water-based epoxy resin curing agent WG-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

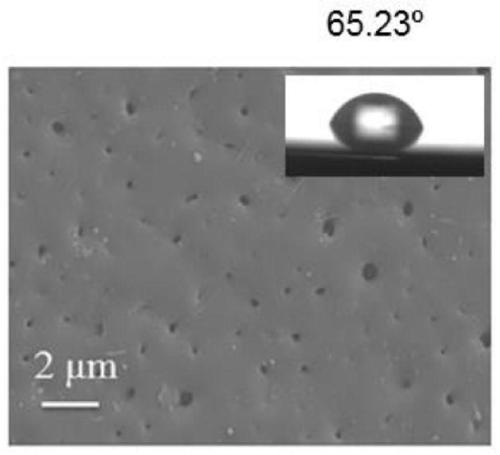

| water contact angle | aaaaa | aaaaa |

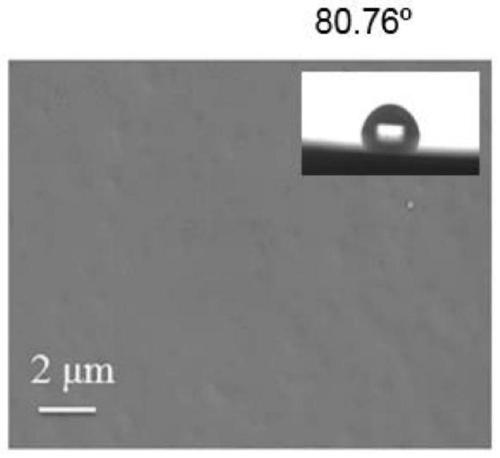

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com