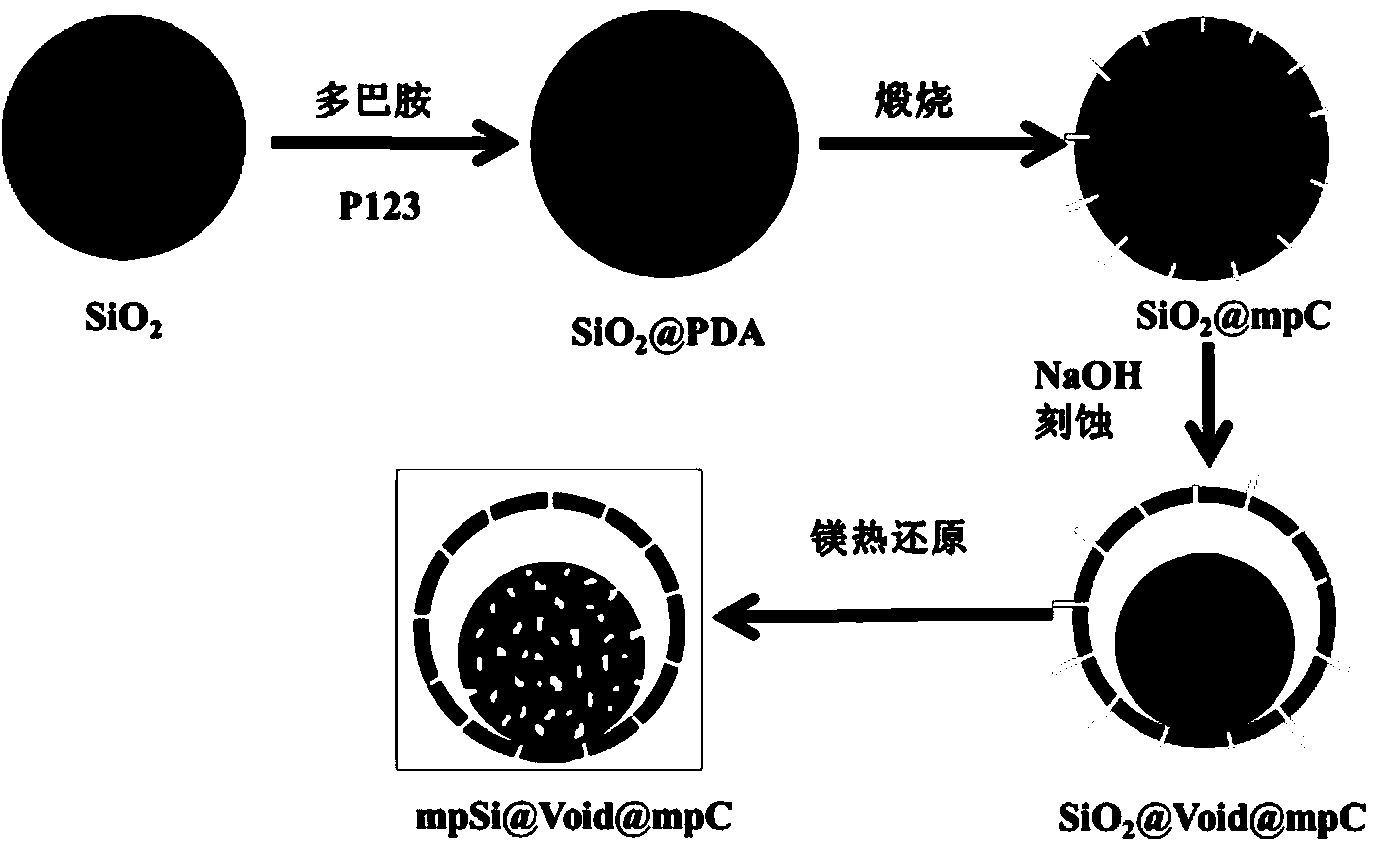

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

A silicon-carbon composite, porous silicon technology, applied in structural parts, nanotechnology for materials and surface science, electrical components, etc., can solve the problems of insufficient silicon expansion space, poor structural stability, etc., to facilitate large-scale Production, guaranteed stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

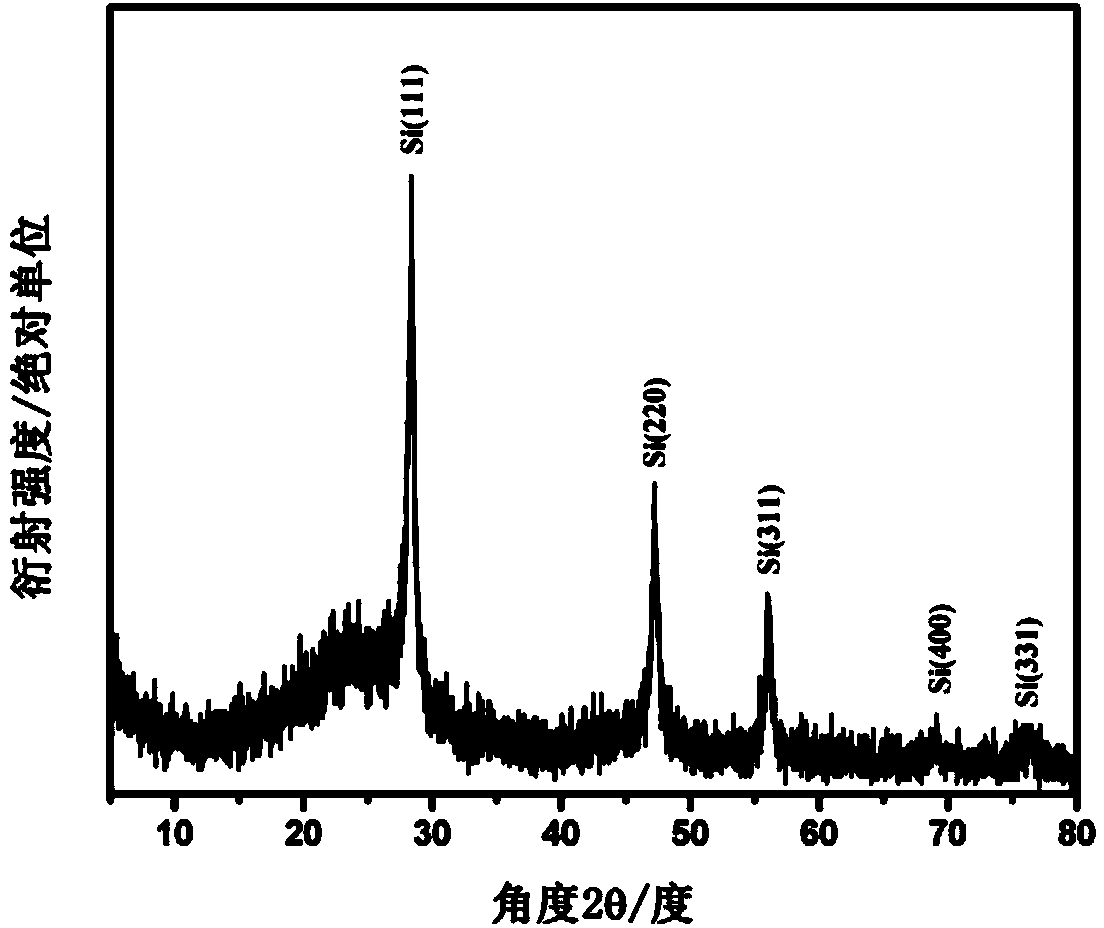

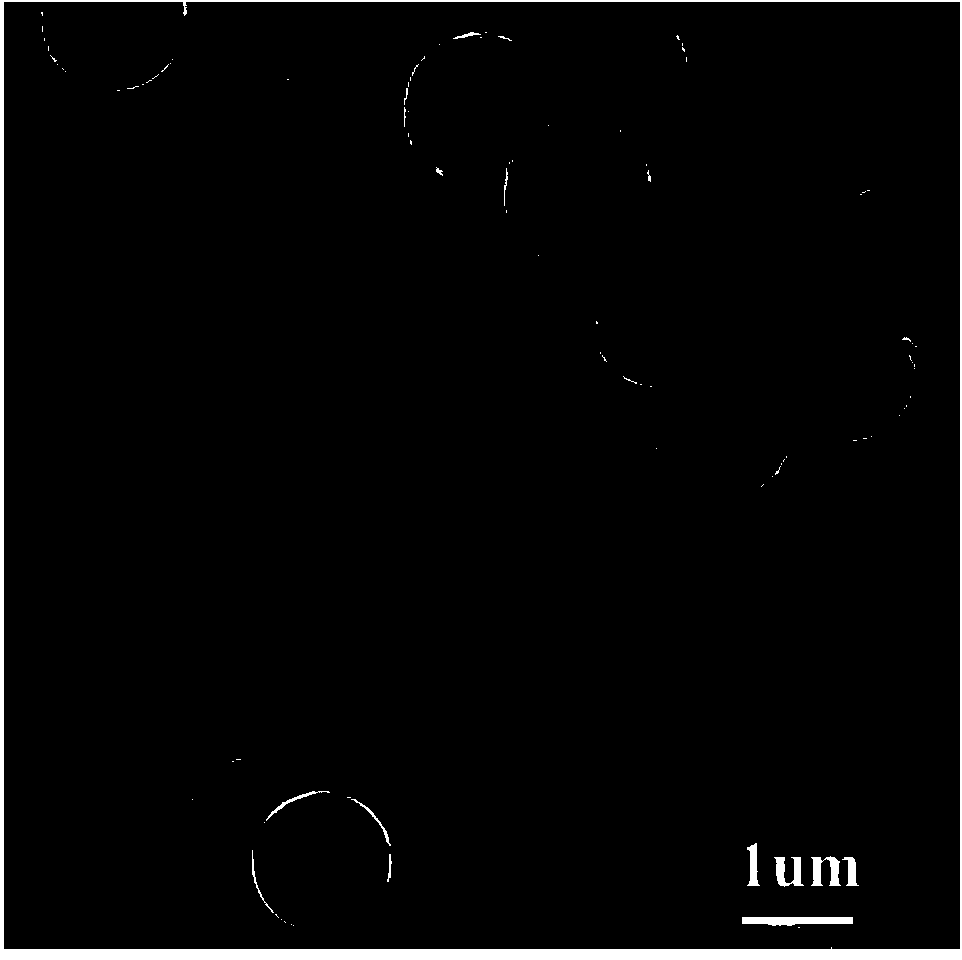

[0022]Weigh 400mg of silica pellet powder with a diameter of 1000nm and disperse it in 200mL water to form a suspension, add trishydroxymethylaminomethane while stirring, and adjust the pH value of the suspension to 8; then weigh 400mg of P123, add Add it into the suspension, stir it magnetically to make it evenly dispersed; then weigh 800mg of dopamine, add it to the suspension, stir at room temperature for 12 hours; then wash with deionized water for 3 times to remove unreacted dopamine, and dry at 60°C for 12 hours Polydopamine-coated silica SiO can be obtained 2 The black precipitate of PDA; under the protection of nitrogen gas, the resulting black precipitate is heated to 400°C at a rate of 3°C / min and kept for 1 hour, then raised to 800°C at a rate of 5°C / min and kept for 5 hours. Porous carbon-coated silica SiO can be obtained 2 Black powder of mpC.

[0023] Put 500mg of the above carbonized black powder in 60mL of NaOH aqueous solution with a substance concentration ...

Embodiment 2

[0026] Weigh 400mg of silica pellet powder with a diameter of 900nm and disperse it in 133mL of water to form a suspension, add trishydroxymethylaminomethane while stirring, and adjust the pH value of the suspension to 9; then weigh 200mg of P123, add Add it into the suspension, stir it magnetically to disperse it evenly; then weigh 400mg of dopamine, add it to the suspension, stir at room temperature for 24 hours; then wash with deionized water for 4 times to remove unreacted dopamine, and dry at 70°C for 10 hours Polydopamine-coated silica SiO can be obtained 2 The black precipitate of PDA; under the protection of nitrogen gas, the resulting black precipitate was heated to 350°C at a rate of 2°C / min and kept for 2 hours, then raised to 850°C at a rate of 4°C / min and kept for 3 hours. Porous carbon-coated silica SiO can be obtained 2 Black powder of mpC.

[0027] Put 475mg of the above carbonized black powder in 60mL of NaOH aqueous solution with a substance concentration o...

Embodiment 3

[0030] Weigh 400mg of silicon dioxide pellets with a diameter of 1300nm and disperse them in 100mL of water to make a suspension, add trishydroxymethylaminomethane while stirring, and adjust the pH value of the suspension to 8; then weigh 100mg of P123, add to In the suspension, stir magnetically to make it evenly dispersed; then weigh 200 mg of dopamine, add it to the suspension, and stir at room temperature for 24 hours; then wash with deionized water for 5 times to remove unreacted dopamine, and dry at 80°C for 8 hours. Available polydopamine-coated silica SiO 2 The black precipitate of PDA; under the protection of nitrogen gas, the resulting black precipitate was heated to 400°C at a rate of 1°C / min and kept for 2 hours, then raised to 900°C at a rate of 5°C / min and kept for 4 hours. Porous carbon-coated silica SiO can be obtained 2 Black powder of mpC.

[0031] Put 450mg of the above carbonized black powder in 60mL of NaOH aqueous solution with a substance concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com