Method for preparing silicon nitride/silicon carbide porous ceramic

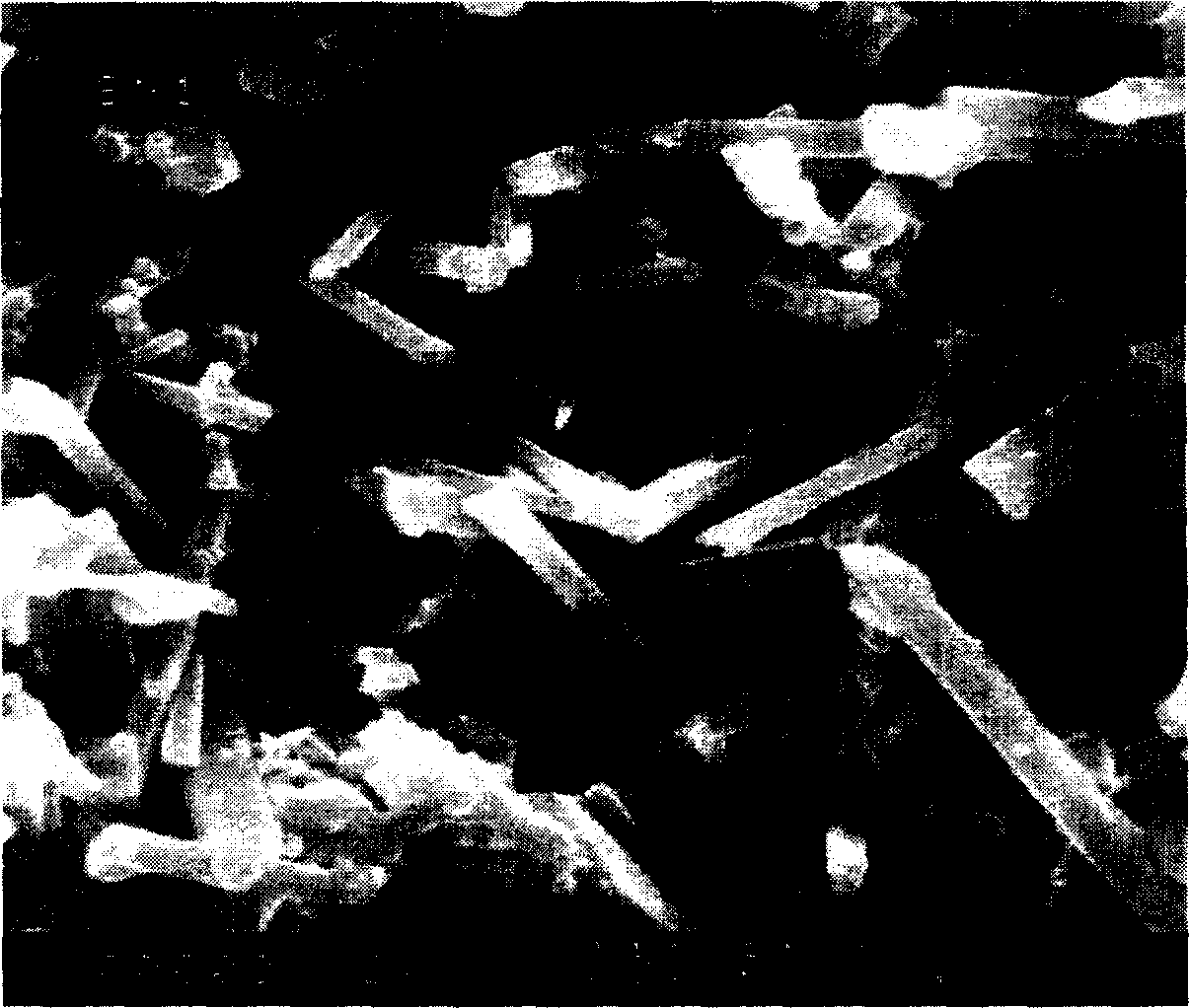

A technology of porous ceramics and silicon nitride, applied in the field of porous ceramics, can solve the problems of high cost and low strength of porous ceramics, and achieve the effects of increasing strength, preventing grain growth and uniform pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

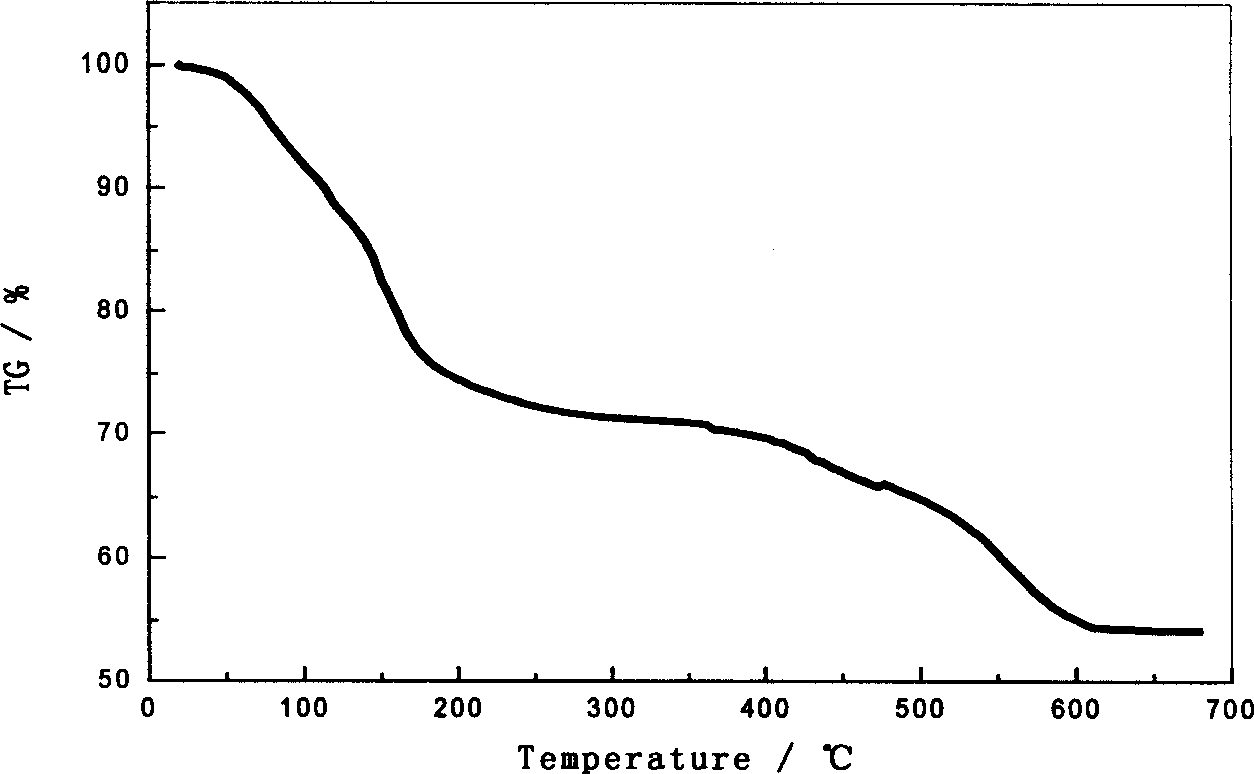

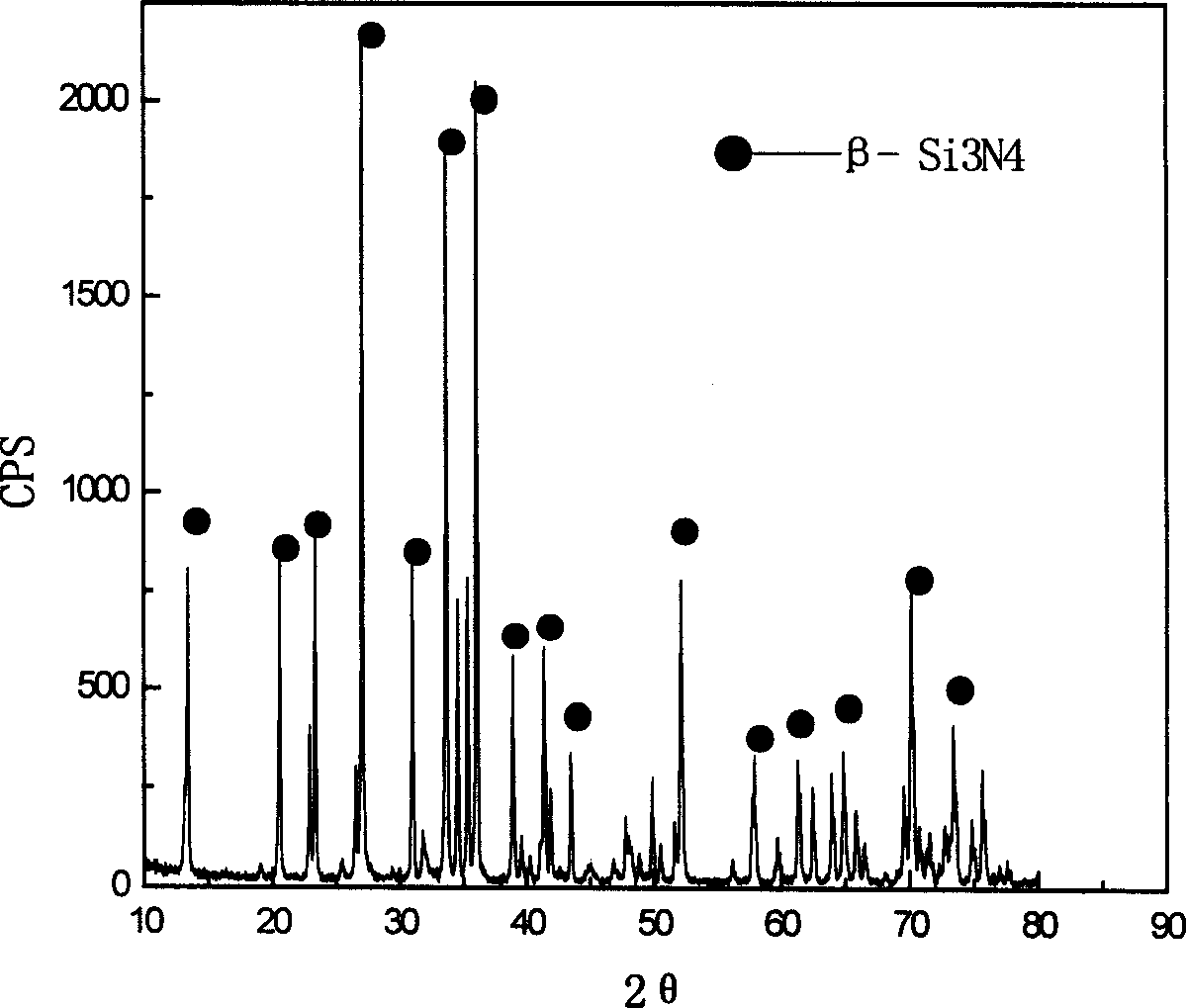

[0036] As shown in embodiment 1, concrete process steps are:

[0037] 1. Si 3 N 4 : Al 2 o 3 : Y 2 o 3 Be 95%: 2%: 10% proportioning by mass percent;

[0038] 2. Add absolute ethanol according to 60% of the total mass percentage of the powder; use agate balls as grinding balls, the mass ratio of powder to agate balls is 1:2, and mix and grind for 24 hours;

[0039]3. Dry the slurry, and dry-press the dried ceramic powder on a press with a pressure of 20Mpa;

[0040] 4. Sintering under vacuum / argon / nitrogen protective atmosphere; the sintering process is carried out in stages: the heating rate is 1°C / min below 800°C, and the atmosphere is vacuum; the heating rate is 3°C / min below 1400°C, and the heat preservation is 2 hours at 1400°C , the atmosphere is argon; finally the sintering temperature is raised to 1780°C at 10°C / min, the atmosphere is nitrogen, and the temperature is kept for 1 hour. The porosity of the product is 51.2%, and the bending strength is 92.4±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com