Antheraea pernyi silk fibrion biology medicine material and the preparation method

A technology of tussah silk fibroin and biomedical materials, which is applied in the field of biomedical materials and can solve the problems of inability to meet the requirements of three-dimensional stent shaping and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

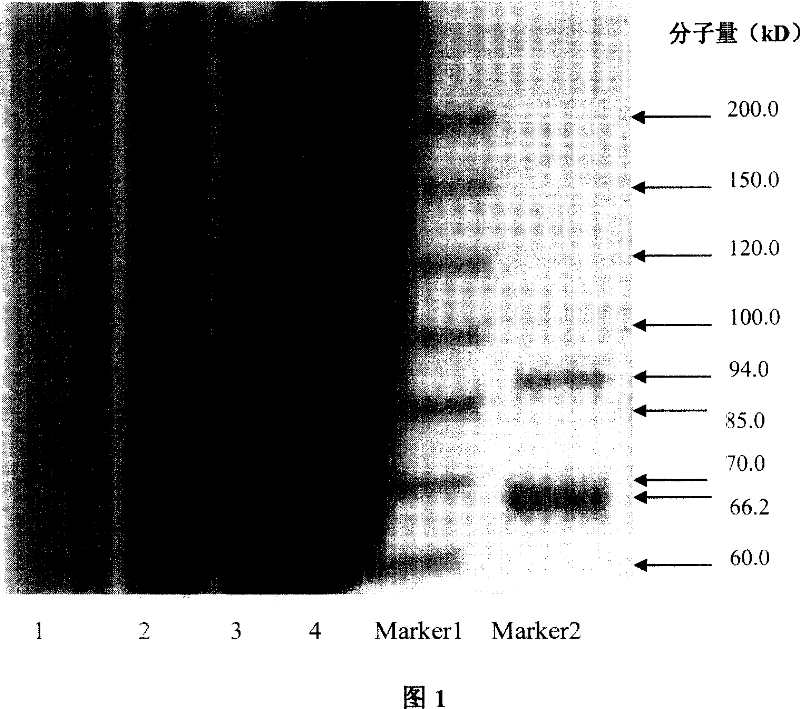

Image

Examples

Embodiment 1

[0022] 1. Put 0.6 kg of leftover tussah silk (a by-product of a silk reeling factory) into 10 liters of 0.05% sodium carbonate aqueous solution, boil for 0.5 hours, repeat the treatment three times, and remove the sericin around the fibroin to obtain pure tussah silk white;

[0023] 2. Put the pure tussah silk fibroin after natural drying into a ternary solution with a weight ratio of lithium thiocyanate: mercaptoethanol: urea of 80:5:5 by weight, at a temperature of 60°C Dissolved under high temperature for 20 hours, purified by filtration and ultrafiltration, ultrasonic defoaming for 1 hour, and dried to make pure tussah silk fibroin;

[0024] 3. Put the pure tussah silk fibroin protein in formic acid solution, dissolve it for 4 hours at a temperature of 30°C, the final concentration of the solution is 10%, filter, purify, and defoam to make spinning raw materials;

[0025] 4. Using the electrospinning method, the distance from the receiving plate to the spinneret is 10cm...

Embodiment 2

[0028] 1. Put 1 kg of cocoon layer into 20 liters of neutral soap solution with a concentration of 0.5%, boil it for 2 hours, remove the sericin around the silk fibroin, wash it thoroughly with hot water to obtain pure tussah silk fibroin;

[0029] 2. Place the dried pure tussah silk fibroin in a ternary solution of lithium thiocyanate: mercaptoethanol: urea = 85:5:10 by weight, and treat it for 50 hours at a temperature of 40°C. Dissolved into tussah silk fibroin protein solution, purified by filtration, dialysis, and dried into pure tussah silk fibroin protein;

[0030] 3. Put the pure tussah silk fibroin and polylactic acid with a mass ratio of 90:10 in a formic acid solution with a concentration of 80%, dissolve them for 2 hours at a temperature of 50°C, purify by filtration, and defoam Make the spinning stock solution that the final concentration of solution is 10%;

[0031] 4. Electrospinning is used to spray the above spinning stock solution according to conventional c...

Embodiment 3

[0034] 1, prepare pure tussah silk fibroin by the method for step 1 in embodiment one;

[0035] 2. Treat the dried pure tussah silk fibroin in a solution of lithium thiocyanate: mercaptoethanol: urea = 98:1:1 by weight at a temperature of 80°C for 5 hours, and obtain tussah silkworm after dissolving Silk fibroin solution, filtered, purified, and dried into pure tussah silk fibroin;

[0036] 3. Put pure tussah silk fibroin and gelatin in a mass ratio of 80:20 in hexafluoroisopropanol solution, dissolve at 20°C for 150 hours, filter, purify, and defoam The final concentration of the solution is 5% spinning raw material;

[0037] 4. Using the electrospinning method, the distance from the receiving plate to the spinneret is 15cm, and the voltage is 15KV to spray the above spinning stock solution to obtain a three-dimensional non-woven fabric composed of fibers with a tussah silk fibroin content of 80% and a gelatin content of 20%. Biomedical materials with spun mesh structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com