Polyethylene corrugated pipe and preparation method thereof

The technology of polyethylene and corrugated pipes is applied in the field of polyethylene corrugated pipes and their preparation, which can solve the problems of rising cost of pipe wall thickness, layered collapse of pipes, large decrease in rigidity, etc., and achieves low requirements, low cost, and impact resistance. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

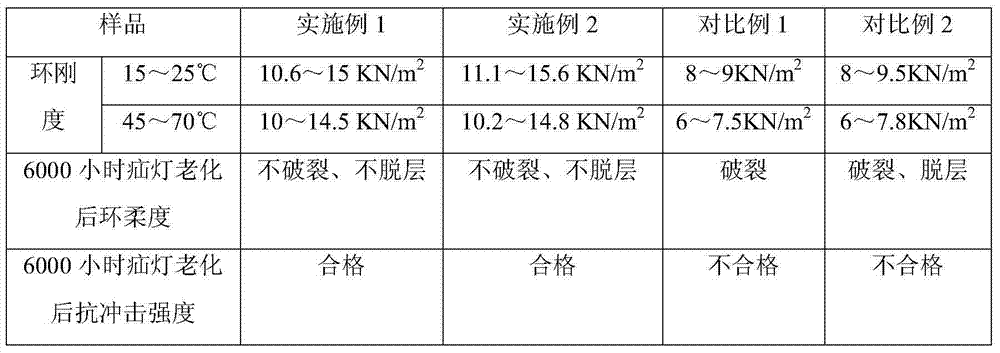

Examples

Embodiment 1

[0041] a, initial mixing: with 80 kilograms of high-density polyethylene, 10 kilograms of ultra-high molecular weight polyethylene, 1.7 kilograms of linear low-density polyethylene, 5 kilograms of isotactic polypropylene, 3 kilograms of α-modified polypropylene, 3 kilograms of maleic anhydride Branched ethylene copolymer, 3 kg of propylene-ethylene copolymer, 8 kg of quartz sand masterbatch, 0.5 kg of phosphite antioxidant, 0.8 kg of benzophenone, 1 kg of black carbon black, 0.5 kg of nano-silica at 23 Stir for 4 minutes under the condition of ℃ to obtain the primary mixture. After the stirring is completed, control the temperature of the primary mixture at 40°C and send it to the next process for use;

[0042] b. Pelletizing: Add the primary compound in step a into a twin-screw extruder to extrude and granulate. The third zone of the barrel is 185°C, the fourth zone of the barrel is 190°C, the fifth zone of the barrel is 200°C, the first zone of the machine head is 185°C, the...

Embodiment 2

[0049] a, initial mixing: with 60 kilograms of high-density polyethylene, 20 kilograms of ultra-high molecular weight polyethylene, 3 kilograms of low-density polyethylene, 16 kilograms of isotactic polypropylene, 2 kilograms of β-modified polypropylene, ethylene-vinyl acetate copolymer 2.8 Kilogram, 3 kilograms of propylene-ethylene copolymers, 8 kilograms of talcum powder, 0.55 kilograms of phenolic antioxidants, 0.7 kilograms of benzoic acid esters, 1.0 kilograms of white carbon black, and 4 kilograms of nano-titanium dioxide were stirred for 3.5 minutes at 25 ° C to obtain For primary mixing, control the temperature of the primary mixing at 42°C and send it to the next process for use;

[0050] b. Granulation: Extrude and granulate the primary mixture obtained in the previous process with a twin-screw extruder. The granulation temperature is: 145°C in the first zone of the barrel, 173°C in the second zone of the barrel, and 173°C in the third zone of the barrel 188°C, 190°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com