Preparation method and application of composite-layer pavement brick

A composite layer and pavement brick technology, which is applied in the field of pavement bricks, can solve the problems of short service life, easy peeling off and fracture of the skin, and achieve the effects of low overall cost, simple and excellent preparation method, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

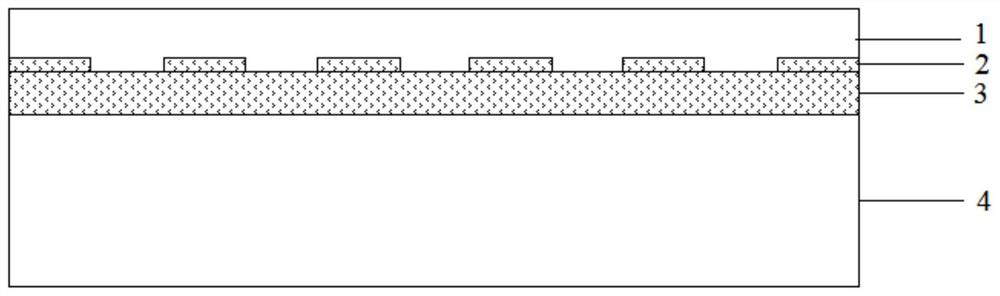

[0024] The first aspect of the embodiment of the present application provides a method for preparing a composite layer pavement brick. The preparation method of composite layer pavement brick, comprises the steps:

[0025] S01. Separately provide the surface layer raw material mixture and the bottom layer raw material mixture for composite layer pavement bricks;

[0026] S02. Provide a mold, place the surface layer raw material mixture in the mold and perform vacuum pressing to obtain a pre-surface layer;

[0027] S03. Open grooves on the surface of the pre-surface layer in the mold, place crushed stones in the mold and perform a pressing process to obtain a pre-connected layer;

[0028] S04. Lay the bottom layer raw material mixture on the surface of the pre-connection layer and carry out vacuum exhaust treatment to form a pre-bottom layer, and obtain a composite layer of the pre-surface layer and the pre-bottom layer connected by the pre-connection layer;

[0029] S05. Aft...

Embodiment 1

[0079] Composite layer pavement brick and its preparation method

[0080] Composite ply brick

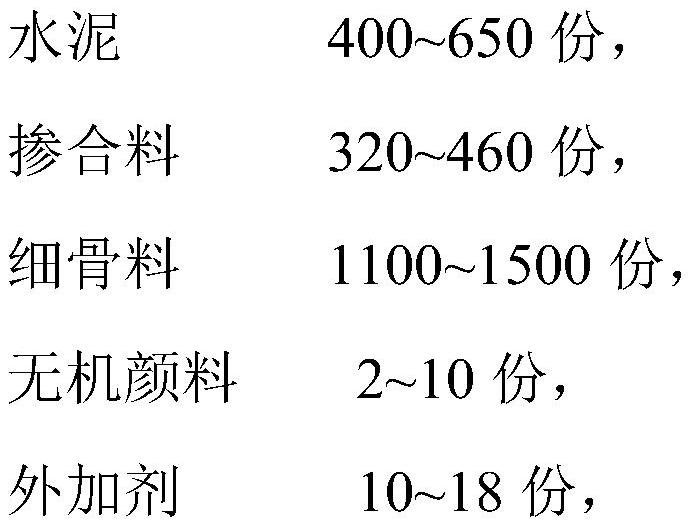

[0081] The composite ply pavement brick comprises a surface layer and a bottom layer, wherein the surface layer raw material mixture includes the following raw materials in parts by weight:

[0082]

[0083] Control the mass ratio of the water added and the cement of the surface course to be 0.16;

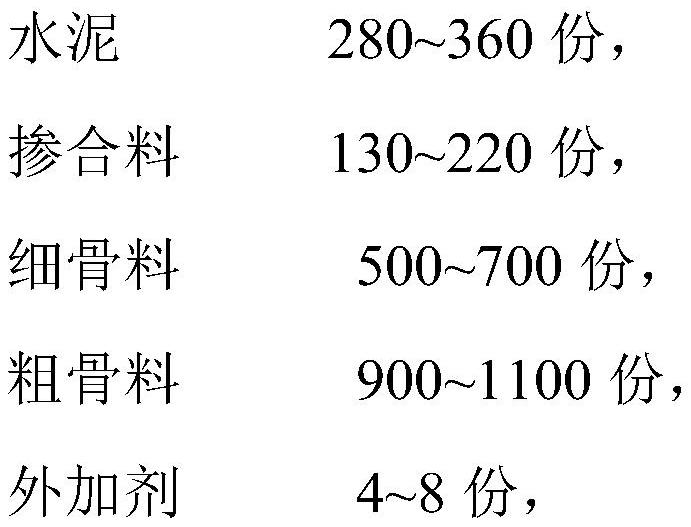

[0084] The bottom raw material mixture comprises the following raw materials in parts by weight:

[0085]

[0086]

[0087] Control the mass ratio of the water that adds and the cement of bottom layer to be 0.28,

[0088] Among them, the cement is selected from Portland cement with a strength > 42.5MPa; the average particle size of the admixture is 5-30 μm; the average particle size of the fine aggregate is 2-4.75mm; the average particle size of the coarse aggregate is 4.75- 25mm.

[0089] A kind of preparation method of composite layer pavement brick

[0090] The prepa...

Embodiment 2

[0098] Composite layer pavement brick and its preparation method

[0099] Composite ply brick

[0100] The composite ply pavement brick comprises a surface layer and a bottom layer, wherein the surface layer raw material mixture includes the following raw materials in parts by weight:

[0101]

[0102] Control the mass ratio of the added water to the cement of the surface layer to be 0.2;

[0103] The bottom raw material mixture comprises the following raw materials in parts by weight:

[0104]

[0105] Control the mass ratio of the water that adds and the cement of bottom layer to be 0.32,

[0106] Among them, the cement is selected from Portland cement with a strength > 42.5MPa; the average particle size of the admixture is 5-30 μm; the average particle size of the fine aggregate is 2-4.75mm; the average particle size of the coarse aggregate is 4.75- 25mm.

[0107] A kind of preparation method of composite layer pavement brick

[0108] The preparation method c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com