Material for bone tissue engineering scaffold and making method thereof

A technology of bone tissue engineering and scaffold materials, applied in bone implants, medical science, prostheses, etc., to achieve good mechanical properties, good biocompatibility, and the effect of inducing cell differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using powder metallurgy method, urea with particle size of 200-500 μm is used as pore-forming agent, fully mixed with magnesium powder (particle size of 100 μm), die-casting at 100 MPa and room temperature, and in Ar 2 Under protection, the pore-forming agent was removed at 473K, and then at 10 -8 The porous magnesium material was prepared by sintering at Pa and 773K with a pore diameter of 250 μm and a porosity of 35%. The measured Young's modulus was 1.8GPa and the compressive strength was 17MPa. The Young's modulus and compressive strength of human bone are 0.01-2GPa, 0.2-80MPa, respectively. It can be seen that the Young's modulus and compressive strength of the prepared porous magnesium are within the required range of human bone, and it can be used as a scaffold material for bone tissue engineering.

Embodiment 2

[0026] The porous magnesium material prepared in Example 1 was put into a simulated body fluid at 37° C. to conduct a corrosion degradation experiment. Samples were taken out regularly, and their degradation was studied by weighing method. The results showed that the porous magnesium was gradually degraded under the action of simulated body fluid, and the degradation rate was about 0.001mm / year. It can be seen that the porous magnesium material can be degraded in the human body and finally completely absorbed by the human body. It can be used as a tissue engineering scaffold material to provide space for cell growth.

Embodiment 3

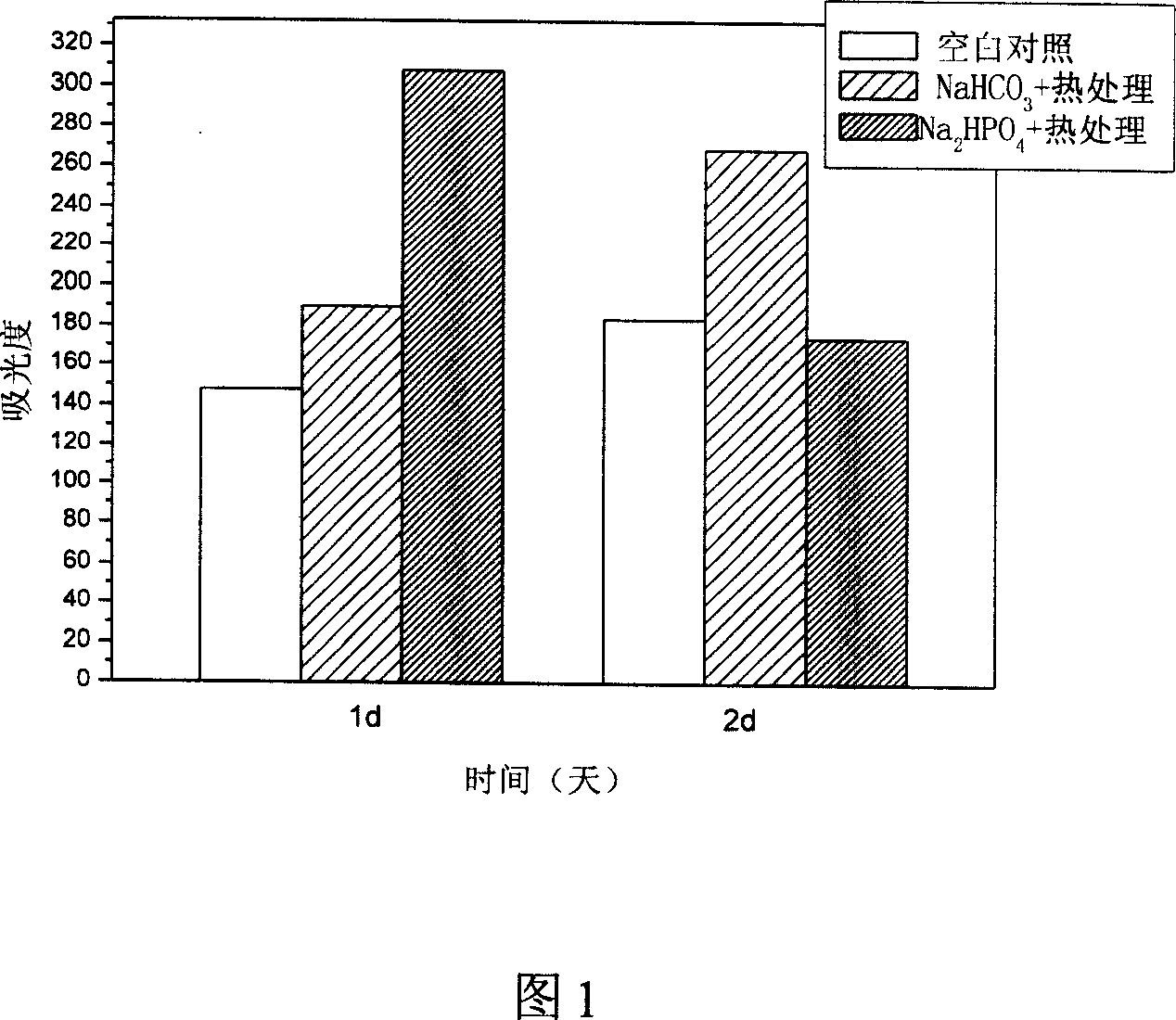

[0028] The porous AZ31 magnesium alloy material prepared by infiltration casting method has a pore diameter of 400 μm, a porosity of 50%, and a compressive strength of 20 MPa. After different alkali heat treatments (respectively in saturated NaHCO 3 and saturated NaHPO 4 Soak in medium for 3h, and heat treatment at 773K for 10h), cultured in vitro with osteoblasts, respectively, after 1 day and 2 days after culture, the amount of cell adhesion on the surface of the sample was tested by the MTT method (expressed in absorbance), and the cells in the blank group were growth as a comparison. The result is shown in Figure 1.

[0029] It can be seen from Figure 1 that cells can adhere to the surface of the prepared porous magnesium material. Compared with the blank group, it was found that the surface treatment of the porous magnesium material not only did not damage the normal growth of cells, but also facilitated the growth of cells, and the number of cells increased compared wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com