Self-temperature-limited polyurethane grouting material and preparation method thereof

A grouting material and self-limiting temperature technology, which is applied in the field of materials, can solve the problems of coal seam spontaneous combustion, open fire accidents, spontaneous combustion, core burning and smoke generation, and achieve the effect of promoting reaction and preventing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

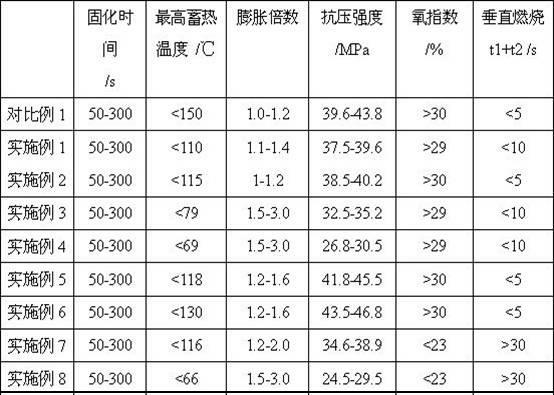

Examples

Embodiment 1

[0040] (1) Weigh 28 grams of toluene diisocyanate (TDI), add 12 grams of prepolymer, and mix the two materials evenly to obtain component A of the grouting material;

[0041] (2) Weigh 26 grams of polyether polyol-220, add 0.4 grams of catalyst triethylenediamine and 0.2 grams of stannous octoate, 0.2 grams of dispersant sodium dodecylbenzene sulfonate, flame retardant ammonium polyphosphate 15 grams, 0.4 grams of defoamer silicone oil, these several materials are mixed homogeneously, obtain the B component of grouting material;

[0042] (3) Prepare the C component of the self-limiting temperature additive, the specific method is: first prepare 8 grams of aqueous solution of sodium hydroxide with a mass fraction of 15%, add 4 grams of sodium chloride, stir and dissolve it to obtain the grouting material The C component;

[0043] (4) Pour the prepared components B and C into component A and stir well to obtain a polyurethane grouting material with good permeability and low hea...

Embodiment 2

[0045] (1) Weigh 40 grams of isocyanate PAPI (brand PM-200) as component A of the grouting material;

[0046] (2) Weigh 26 grams of polyether polyol-210, add 0.3 grams of catalyst hexamethylenetetramine, 0.3 grams of stannous octoate, 0.3 grams of KH570 dispersant, and 15 grams of flame retardant melamine cyanurate, 0.4 grams of defoaming agent silicone oil, these several kinds of materials are mixed uniformly, obtain the B component of grouting material;

[0047] (3) Prepare the C component of the self-limiting temperature additive. The specific method is: first prepare 8 grams of an aqueous solution of sodium acetate with a mass fraction of 15%, add 4 grams of potassium sulfate, and stir it evenly to obtain the C component of the grouting material. components;

[0048] (4) Pour the prepared components B and C into component A and stir well to obtain a polyurethane grouting material with good permeability and low heat storage temperature.

Embodiment 3

[0050] (1) Weigh 32 grams of isocyanate PAPI (brand PM-130), add 8 grams of polyurethane prepolymer, mix the two materials evenly, and obtain component A of the grouting material;

[0051] (2) Weigh 26 grams of polyether polyol-303, add 0.5 grams of catalyst triethylenediamine, 0.4 grams of polyvinyl alcohol dispersant, 12 grams of melamine phosphate flame retardant, and 1.3 grams of ethylene glycol chain extender , 0.3 gram of silicone oil, these several kinds of materials are mixed homogeneously, obtain the B component of grouting material;

[0052] (3) Prepare the C component of the self-limiting temperature additive. The specific method is: first make a total of 2 grams of an aqueous solution of potassium oxalate with a mass fraction of 20%, add 10.8 grams of n-heptane, and stir it evenly to obtain the grouting material. C component;

[0053] (4) Pour the prepared components B and C into component A and stir well to obtain a polyurethane grouting material with good permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com