A low heat storage temperature, antistatic grouting reinforcement material and preparation method thereof

A grouting reinforcement and antistatic technology, applied in the field of coal and rock mass reinforcement, can solve the problems of high heat storage temperature of polyurethane grouting materials, affecting the use and popularization and application, poor antistatic performance, etc., to promote heat conduction and easy to popularize and use , Improve the effect of antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

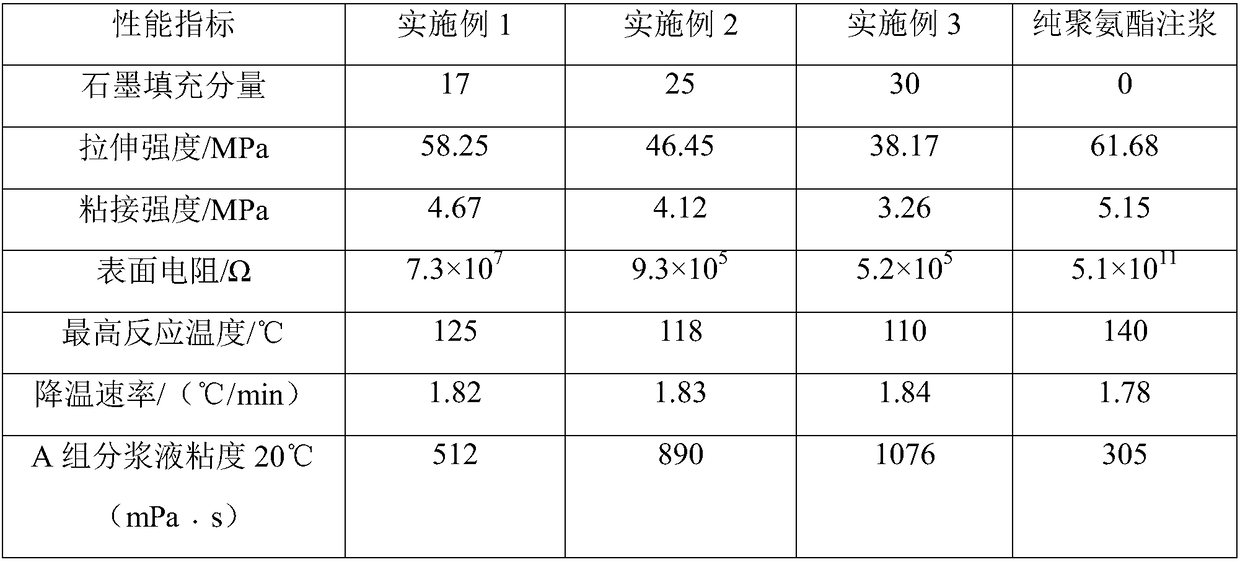

Embodiment 1

[0030] 1) Mix 17 parts by mass of graphite (20 μm in particle size) and 100 parts by mass of PAPI, stir at 25°C for 2 hours, seal and store to obtain Component A;

[0031] 2) Place polyether polyol N303 (functionality 3, molecular weight 350) and polyether polyol N204 (functionality 2, molecular weight 400) in a vacuum drying oven, dry at 105°C for 2 hours, cool to room temperature and seal Save to obtain pretreated polyether polyol N303 and pretreated polyether polyol N204;

[0032] 3) Mix 50 parts by mass of pretreated polyether polyol N303 and 30 parts by mass of pretreated polyether polyol N204 evenly, then add 0.5 parts by mass of dibutyltin dilaurate and 10 parts by mass of TCEP in sequence, and stir evenly Obtain component B;

[0033] 4) Mix component A and component B according to the volume ratio of 1:1, stir until whitening occurs, inject into the mold under 3-5MPa pressure, and cure at room temperature for 3-5 minutes. After curing, the samples were taken out, and...

Embodiment 2

[0035] 1) Mix 25 parts by mass of graphite (particle size: 20 μm) and 100 parts by mass of PAPI, stir at 25°C for 2 hours, seal and store to obtain Component A;

[0036] 2) Place polyether polyol N303 (functionality 3, molecular weight 350) and polyether polyol N204 (functionality 2, molecular weight 400) in a vacuum drying oven, dry at 105°C for 2 hours, cool to room temperature and seal Save to obtain pretreated polyether polyol N303 and pretreated polyether polyol N204;

[0037] 3) Mix 50 parts by mass of pretreated polyether polyol N303 and 30 parts by mass of pretreated polyether polyol N204 evenly, then add 0.5 parts by mass of dibutyltin dilaurate and 10 parts by mass of TCEP in sequence, and stir evenly Obtain component B;

[0038] 4) Mix component A and component B according to the volume ratio of 1:1, stir until whitening occurs, inject into the mold under 3-5MPa pressure, and cure at room temperature for 3-5 minutes. After curing, the samples were taken out, and r...

Embodiment 3

[0040] 1) Mix 30 parts by mass of graphite (20 μm in particle size) and 100 parts by mass of PAPI, stir at 25°C for 2 hours, seal and store to obtain Component A;

[0041] 2) Place polyether polyol N303 (functionality 3, molecular weight 350) and polyether polyol N204 (functionality 2, molecular weight 400) in a vacuum drying oven, dry at 105°C for 2 hours, cool to room temperature and seal Save to obtain pretreated polyether polyol N303 and pretreated polyether polyol N204;

[0042] 3) Mix 50 parts by mass of pretreated polyether polyol N303 and 30 parts by mass of pretreated polyether polyol N204 evenly, then add 0.5 parts by mass of dibutyltin dilaurate and 10 parts by mass of TCEP in sequence, and stir evenly Obtain component B;

[0043] 4) Mix component A and component B according to the volume ratio of 1:1, stir until whitening occurs, inject into the mold under 3-5MPa pressure, and cure at room temperature for 3-5 minutes. After curing, the samples were taken out, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com