Combustion jet cutter used for steel structure member cutting

A technology for steel structural parts and cutting bullets, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as large heat loss, low oxygen content, and low jet velocity, and achieve fast reaction speed and high energy density , The effect of cutting and blowing force is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

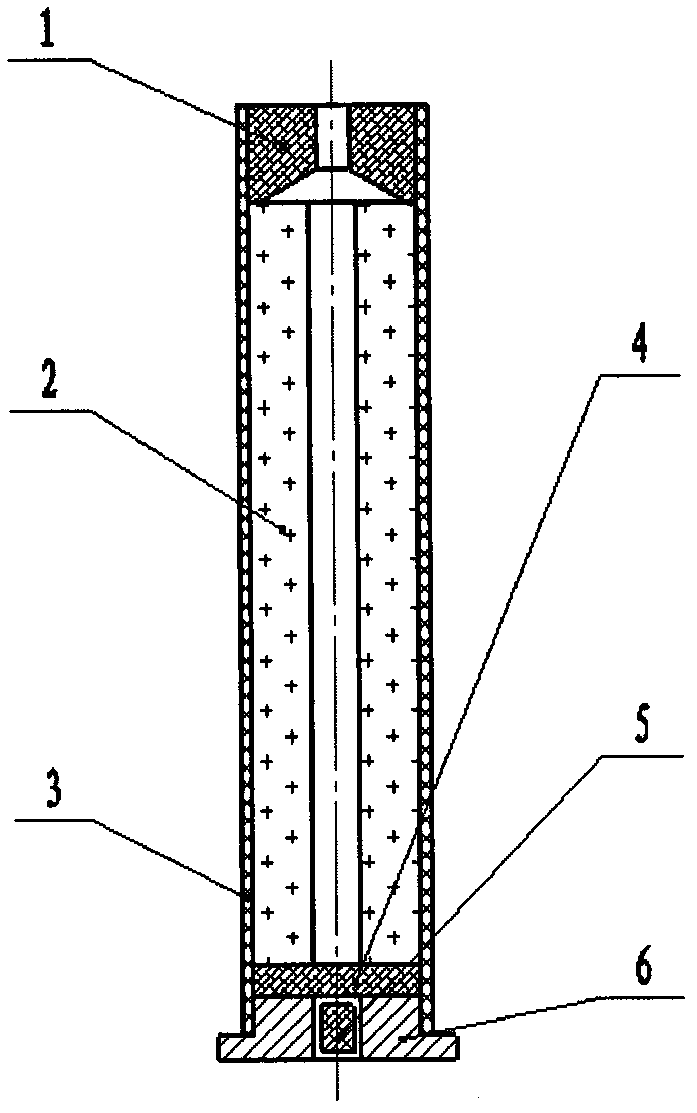

[0013] Combustion type cutting ammunition with an outer diameter of 23mm, full length of the ammunition is 120mm, the primer is the base-6B, and the cartridge case is a 1.5mm thick paper tube; the inner bottom of the ammunition is pressed with a 3mm thick igniter, and the cutting agent is a hollow structure made of solid powder mixed and pressed , the hollow hole is about 6mm in diameter, the front end of the bullet is made of graphite material, the nozzle with the inner cone hole and straight hole structure, the nozzle thickness is 12mm, the diameter of the straight hole is 4mm, the outer diameter of the nozzle is the same as the inner diameter of the cartridge case, and water glass adhesive is used Cartridge inside diameter bonding. The composition of the cutting agent is CuO (-200 mesh) 8% ~ 12%, Fe 2 o 3 (-200 mesh) 45%~50%, Al (-250 mesh) 18%~22%, KNO 3 (-100 mesh) 10%~15%, CaCO 3 (-100 mesh) 2%, Al 2 o 3 (-150 mesh) 1.5%, Cr 2 o 3 (-200 mesh) 1.5%, Ni (-150 mesh) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com