Method of preparing ceramic coating by flame heat spray painting thermit packaged silicon carbide particles

A technology for wrapping silicon carbide and ceramic coatings, which is applied in the field of preparation of thermite-wrapped silicon carbide particle ceramic coatings, which can solve problems such as limitations and achieve the effect of preventing thermal sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

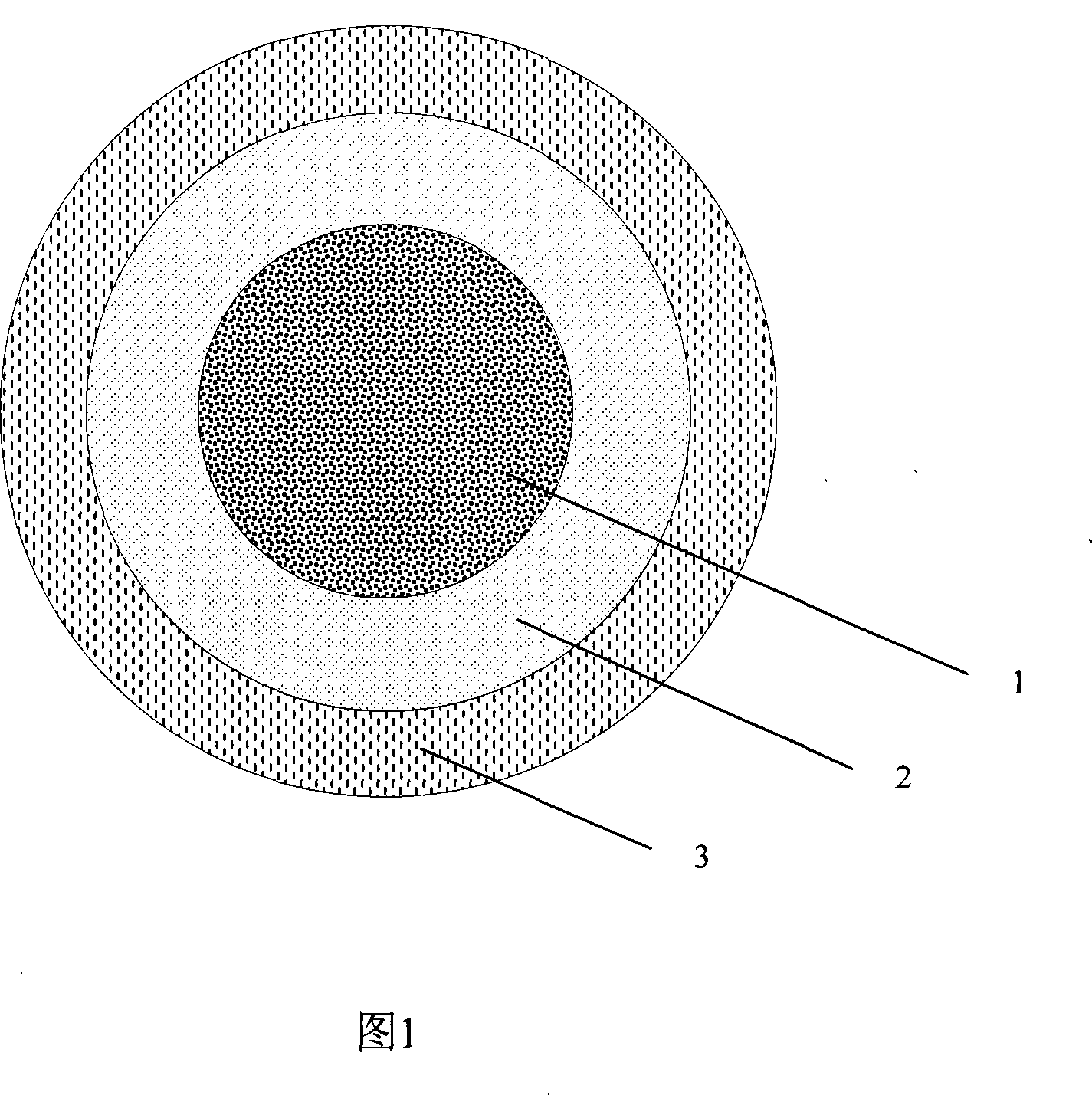

Embodiment 1

[0009] Example 1: First, compound ferric oxide powder of 400-800 mesh with aluminum powder of 400-800 mesh to form a thermite; then combine the thermite with alumina particles of 400-800 mesh and silicon carbide of 400-800 mesh According to the mass ratio of 1:0.5:2.0, the polymer binder with a degree of polymerization of 1000-5000 is recombined and reconstructed, and the particle size is 160-400 mesh. The inner layer is silicon carbide, the middle layer is thermite, and the outer layer is alumina. Spherical composite particles with a three-layer wrapping structure; finally, put the spherical composite particles into a powder hopper of a spray gun for thermal spraying by an oxygen-acetylene flame to form a ceramic coating.

Embodiment 2

[0010] Example 2: First, compound ferric oxide powder of 400-800 mesh with aluminum powder of 400-800 mesh to form a thermite; then combine the thermite with alumina particles of 400-800 mesh and silicon carbide of 400-800 mesh According to the mass ratio of 1:1.0:0.5, it is restructured by polymer binder with a degree of polymerization of 1000-5000, and the particle size is 160-400 mesh. The inner layer is silicon carbide, the middle layer is thermite, and the outer layer is alumina. Spherical composite particles with a three-layer wrapping structure; finally, put the spherical composite particles into a powder hopper of a spray gun for thermal spraying by an oxygen-acetylene flame to form a ceramic coating.

Embodiment 3

[0011] Example 3: First, compound ferric oxide powder of 400-800 mesh with aluminum powder of 400-800 mesh to form a thermite; then combine the thermite with alumina particles of 400-800 mesh and silicon carbide of 400-800 mesh According to the mass ratio of 1:0.1:1.5, it is restructured by polymer binder with a degree of polymerization of 1000-5000, and the particle size is 160-400 mesh. The inner layer is silicon carbide, the middle layer is thermite, and the outer layer is alumina. Spherical composite particles with a three-layer wrapping structure; finally, put the spherical composite particles into a powder hopper of a spray gun for thermal spraying by an oxygen-acetylene flame to form a ceramic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com