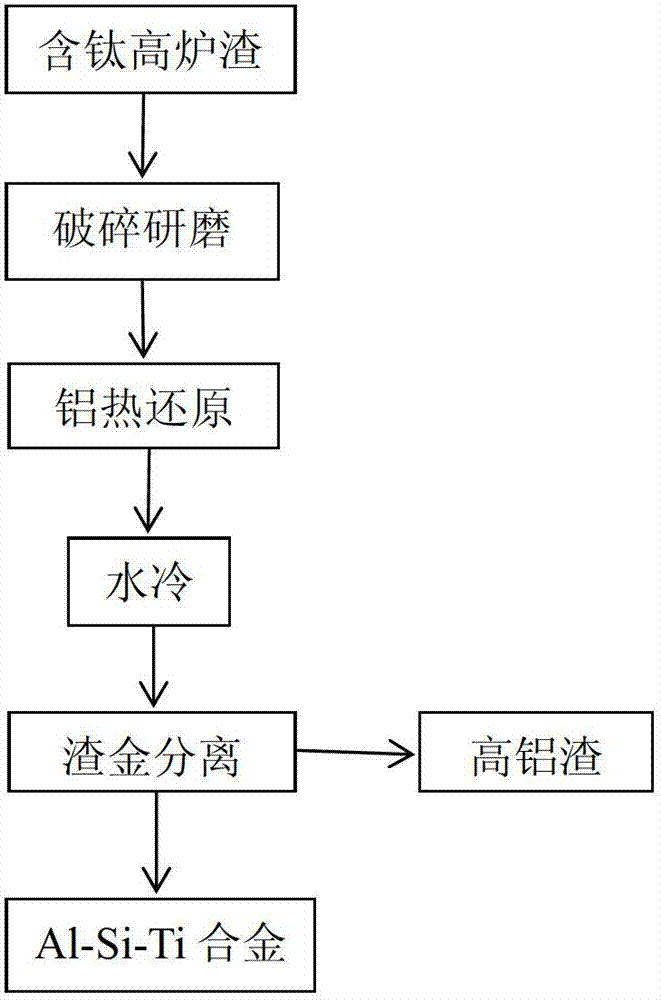

Process for extracting titanium from titanium-containing blast furnace slag through aluminothermic method

A slag aluminothermic and blast furnace slag technology, applied in the field of metallurgy and chemical industry, can solve problems such as restricting large-scale use, and achieve the effects of reducing viscosity, simple process flow and increasing basicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh, and mix well.

[0022] 2) According to the mass ratio of slag:Al:CaO=100:25.98:0, weigh 15.875 grams of titanium-containing blast furnace slag and 4.125 grams of Al powder.

[0023] 3) In an argon protective atmosphere, raise the temperature of the tubular electric furnace to 1600°C. Put the mixed ingredients into the alumina crucible, put the heat into the electric tube furnace, and keep it warm for 10 minutes.

[0024] 4) After the heat preservation is completed, heat it at 1600℃, directly put it in water to cool, and then put it in a drying oven to dry.

[0025] 5) The slag is separated from the alloy, and the slag sample is taken for XRF analysis.

Embodiment approach 2

[0027] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh, and mix well.

[0028] 2) According to the mass ratio of slag:Al:CaO=100:25.98:2.5, weigh 15.567 grams of titanium-containing blast furnace slag, 4.044 grams of Al powder, and 0.389 grams of CaO powder.

[0029] 3) In an argon protective atmosphere, raise the temperature of the tubular electric furnace to 1550°C. Put the mixed ingredients into the alumina crucible, put the heat into the electric tube furnace, and keep it warm for 20 minutes.

[0030] 4) After the heat preservation is completed, heat it at 1600℃, directly put it in water to cool, and then put it in a drying oven to dry.

[0031] 5) The slag is separated from the alloy, and the slag sample is taken for XRF analysis.

Embodiment approach 3

[0033] 1) Crush and grind titanium-containing blast furnace slag to 180 mesh, and mix well.

[0034] 2) According to the mass ratio of slag:Al:CaO=100:25.98:5, weigh 15.269 grams of titanium-containing blast furnace slag, 3.967 grams of Al powder, and 0.764 grams of CaO powder.

[0035] 3) In an argon protective atmosphere, raise the temperature of the tubular electric furnace to 1750°C. Put the mixed ingredients into the alumina crucible, put the heat into the electric tube furnace, and keep it warm for 30 minutes.

[0036] 4) After the heat preservation is completed, heat it at 1600℃, directly put it in water to cool, and then put it in a drying oven to dry.

[0037] 5) The slag is separated from the alloy, and the slag sample is taken for XRF analysis.

[0038]

[0039] Table 1 shows the XRF component analysis results of 3 examples of the present invention.

[0040] Al 2 O 3 CaO MgOSiO 2 TiO 2 Original titanium-bearing blast furnace slag15.3526.469.4026.7622.03 Slag: Al: CaO=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com