Over pressure relief system for fluid ends

a technology of relief valve and fluid end, which is applied in the field of hydraulic fracturing, can solve problems such as extreme pressure buildup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

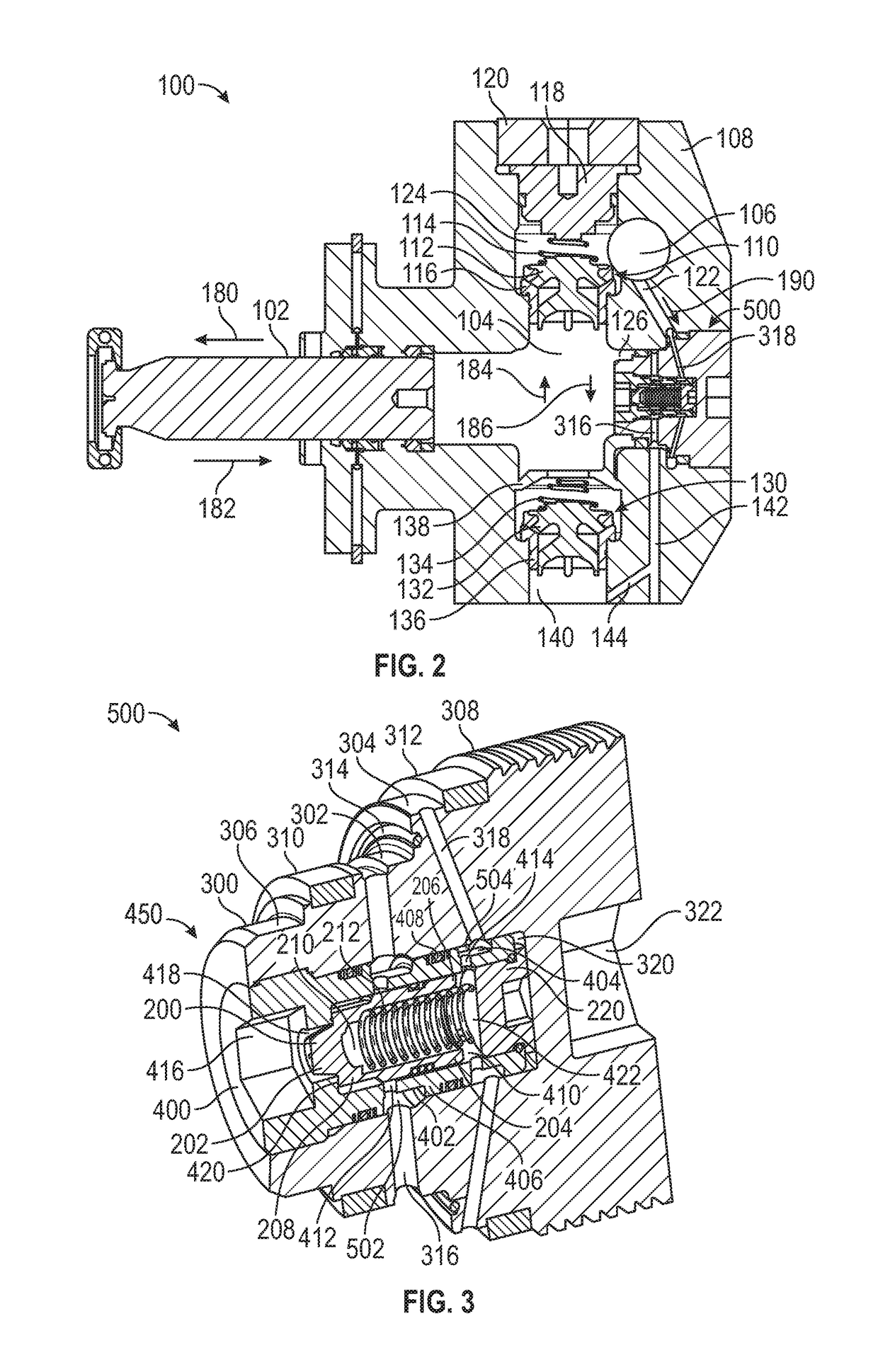

[0012]This disclosure relates to a relief valve assembly for a fluid end. The relief valve assembly provides pressure relief when the fluid end undergoes an overpressure event. The overpressure event can be caused by a valve getting stuck due to various reasons, allowing for the buildup of pressurized fluid mixture in a compression area of the fluid end. The relief valve assembly allows for the pressurized fluid mixture to return to the intake of the fluid mixture, usually a suction cavity. The fluid mixture can then be recycled back into the compression area.

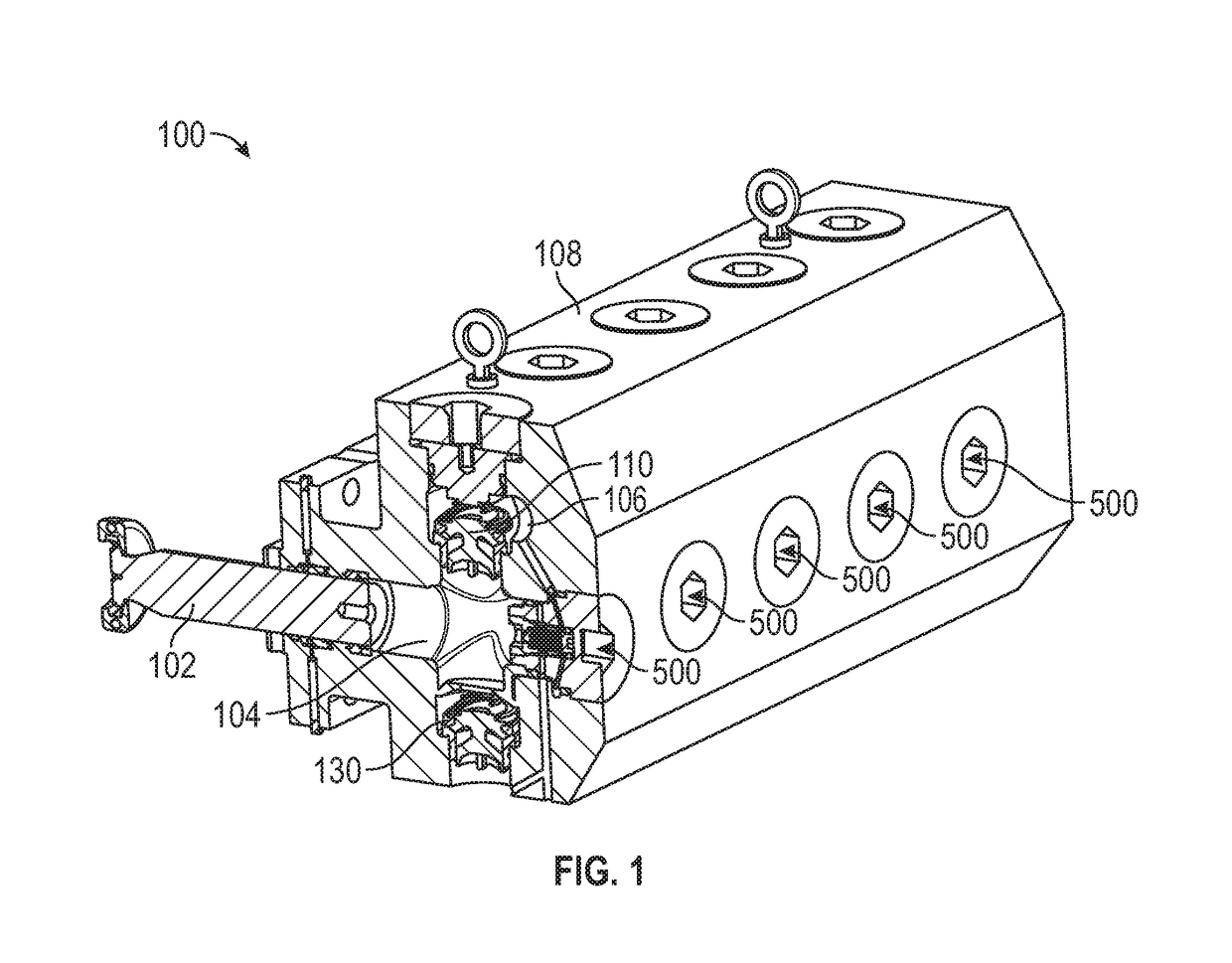

[0013]FIG. 1 is a perspective view illustrating a cross section of a fluid end 100 according to an embodiment of the present disclosure. As shown, fluid end 100 may include a fluid end housing 108, a plunger 102, a compression area 104 (sometimes referred to as a plunger bore), a discharge valve assembly 110, a discharge conduit 106, a suction valve assembly 130, and a relief valve assembly 500. Fluid end housing 108 may enclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com