Full-automatic utility pole centralizer

A utility pole and centralizer technology, applied in the field of automatic utility pole centralizers, can solve problems such as affecting the reliability of power supply, and achieve the effects of ensuring reliability of power supply, improving work efficiency, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

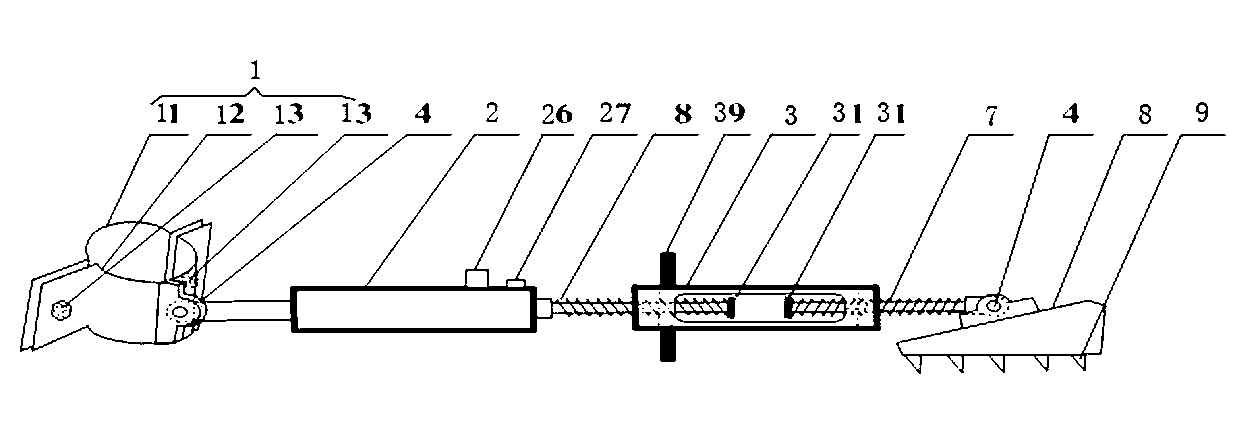

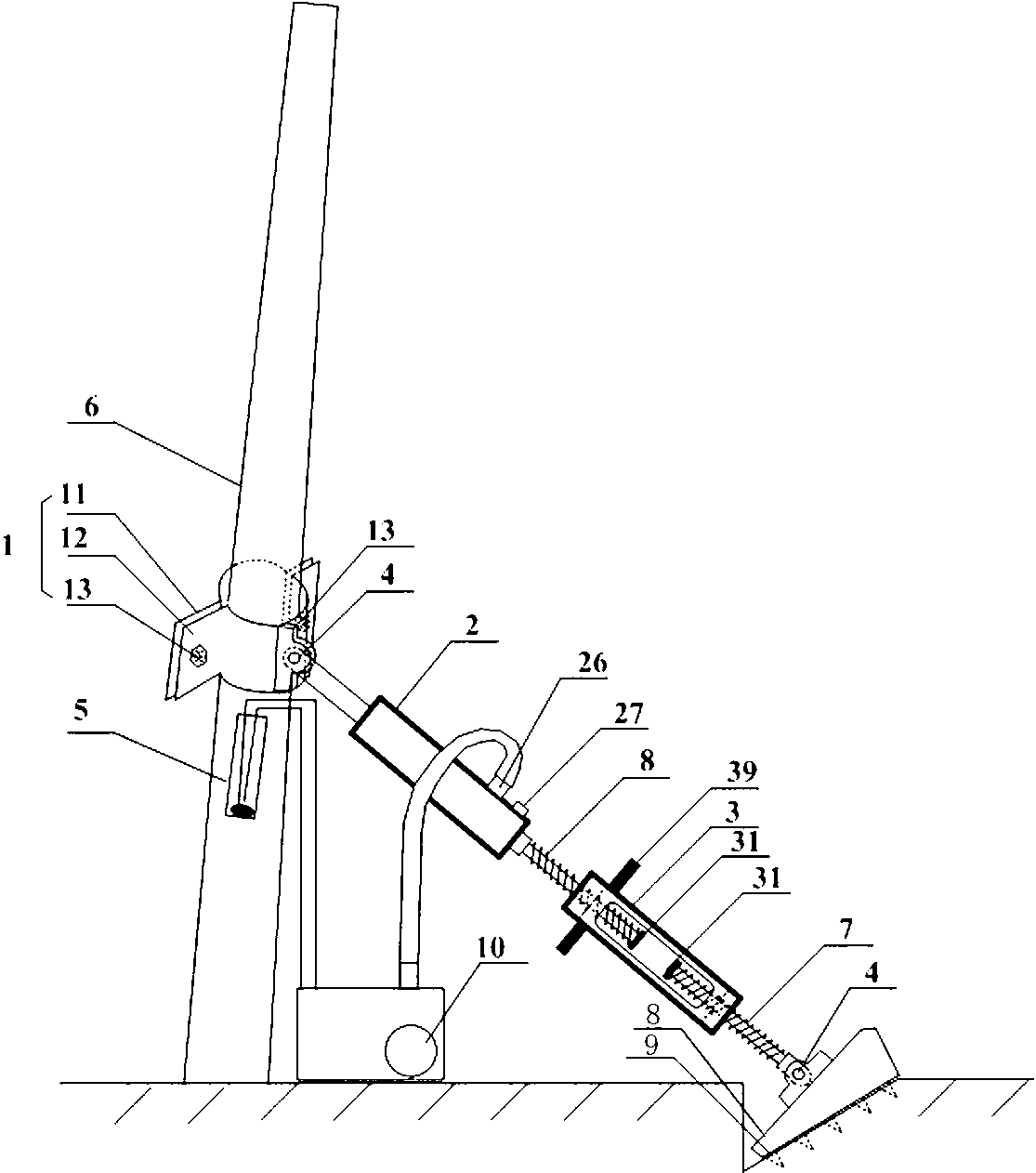

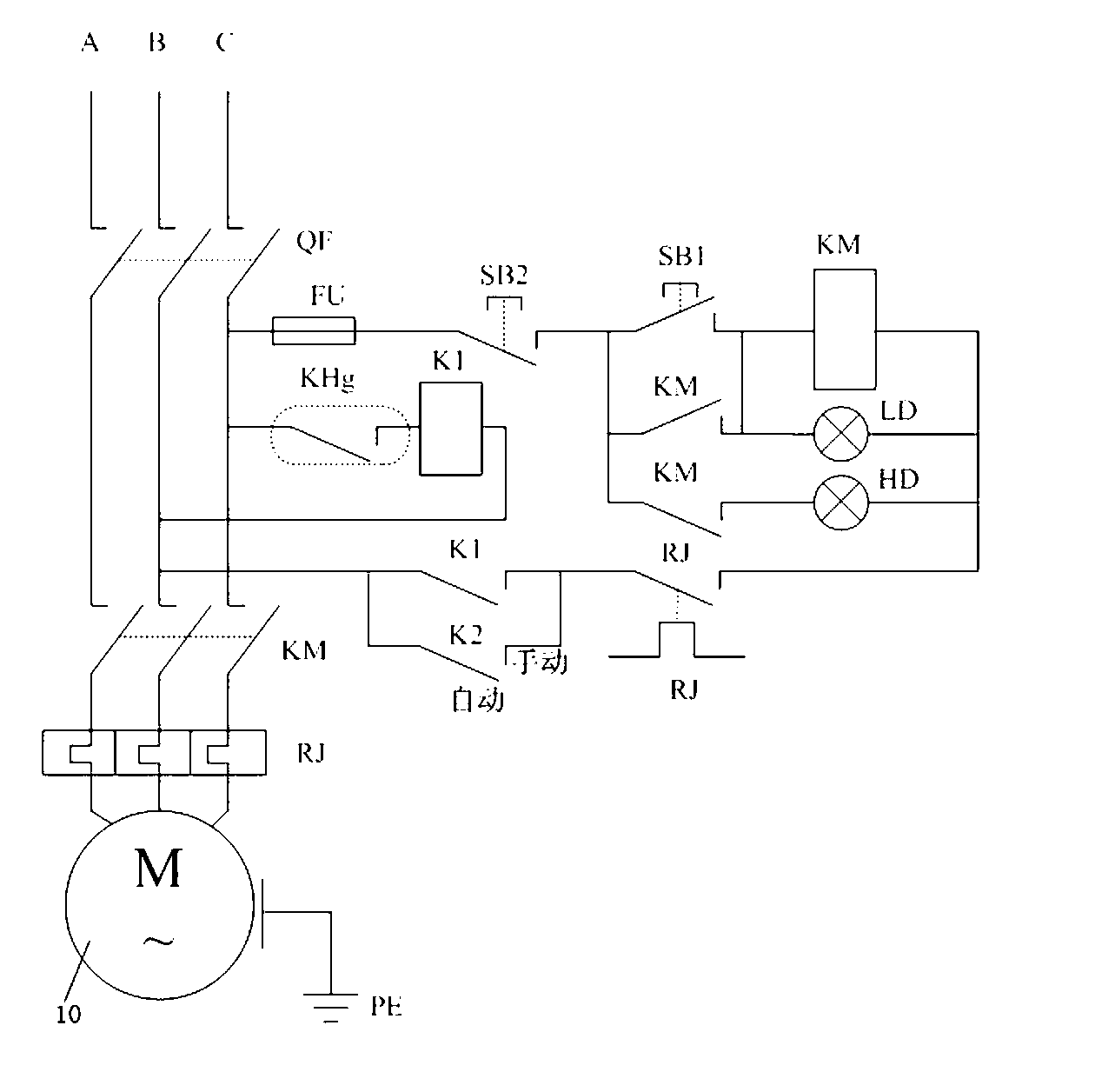

[0015] Such as figure 1 As shown, the automatic pole centralizer of the present invention includes a hoop 1, a hydraulic mechanism 2, a length adjuster 3, a connecting shaft 4, a forward screw screw 8, a reverse screw screw 7, a base 8, a mercury switch 5 and Electric hydraulic pump 10, wherein:

[0016] The hoop 1 includes a left hoop 11 and a right hoop 12, the left hoop 11 and the right hoop 12 are fixed on the utility pole 6 by fixing bolts 13, and the distance between the hoop 1 and the ground is usually 1-2 m, the hoop 1 is connected with the hydraulic mechanism 2 through the connecting shaft 7.

[0017] The hydraulic mechanism 2 is provided with a pressure relief valve 27 and a hydraulic interface 26 .

[0018] The hydraulic mechanism 2 is welded together with one end of the positive buckle screw 8, and the other end of the positive buckle screw 8 is screwed into the length adjuster 3, and the end of the positive buckle screw 8 screwed into the length adjuster 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com