Method for producing corrosion-resistant surfaces of nitrated or nitrocarburated steel components

A carbonitriding and corrosion-resistant technology, which is applied in the manufacture of springs/shock absorbers, shock absorbers, solid-state diffusion coatings, etc., to achieve the effect of shortening processing time and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

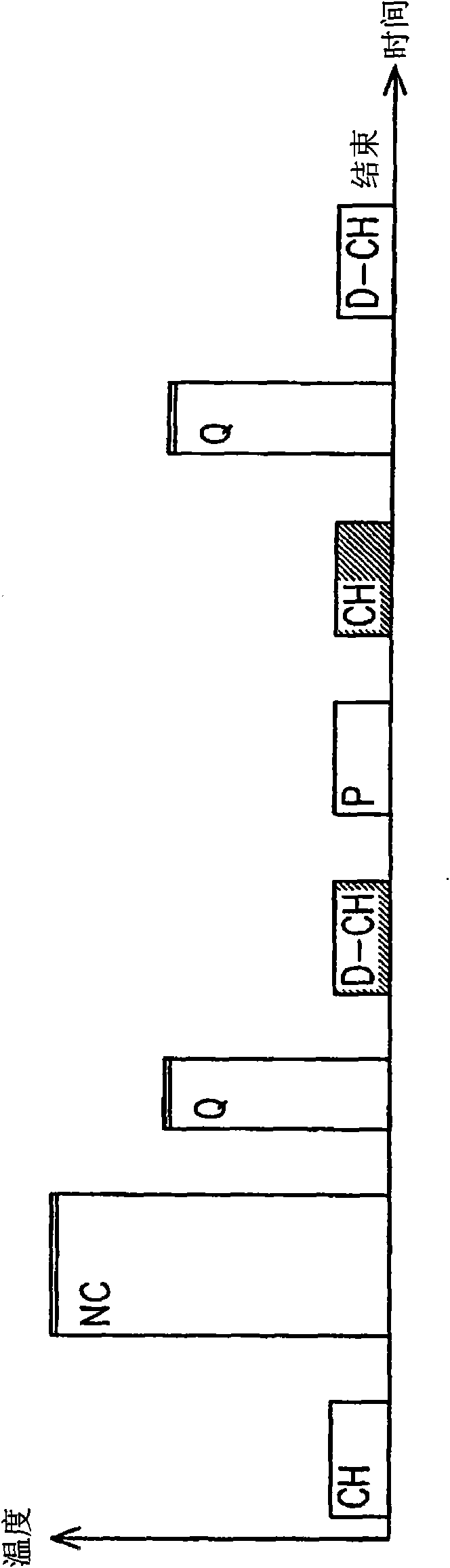

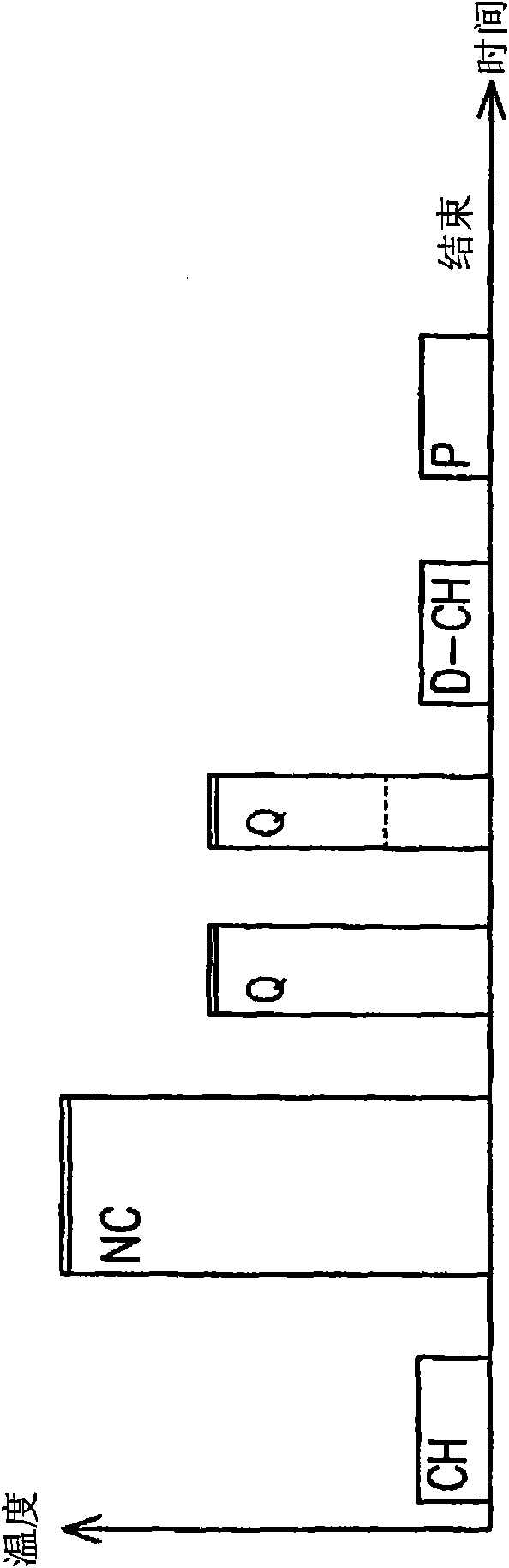

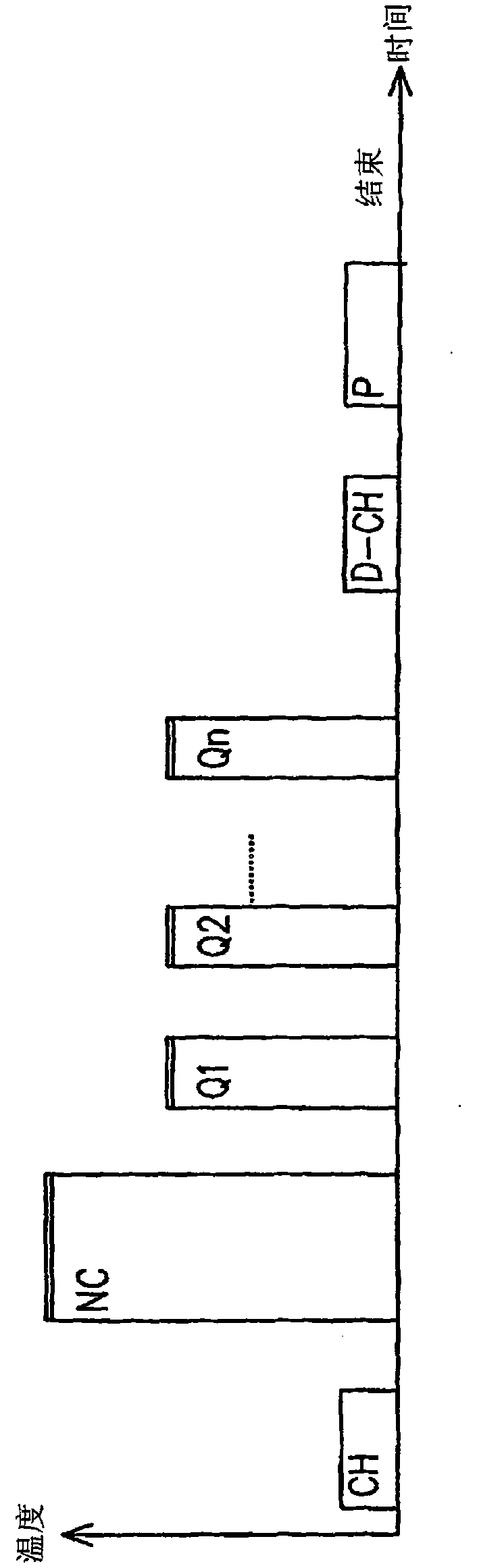

Method used

Image

Examples

Embodiment 1

[0108] 104 connecting rods made of material C45 with a length of 18 cm and a diameter of 12 mm for pneumatic valves in a titanium crucible carbonitriding salt bath in the so-called The standard process conditions of the method (cyanate content is 37.5% by weight, cyanide content is 4.2% by weight, iron content is less than 200ppm, temperature is 580 ℃ + / - 5 ℃, Na in the melt + / K + The carbonitriding was carried out for 90 minutes at a ratio of about 20 / 80), resulting in a bonding layer with a thickness of 18 to 21 μm. The arithmetically averaged average roughness measured according to DIN EN ISO 4287 at 3 different positions along the length of 2 pieces of connecting rods prior to processing of the original part is 0.52 μm Rz.

[0109] After salt bath carbonitriding, the 2 connecting rods were removed and cooled by immersion in water. For the part, the roughness measured in the same way rises to an average value of Rz = 1.82 μm.

[0110] The remaining 102 connecting rod...

Embodiment 2

[0120] 27 connecting rods made of material C35 with a length of 27 cm and a diameter of 8 mm used as connecting rods in a gas spring in a titanium crucible In the carbonitriding salt bath in the following according to the so-called Carbonitriding at 600°C + / - 5°C for 60 minutes under the process conditions of the method (cyanate content 37.5% by weight, cyanide content 4.2% by weight, iron content less than 200ppm) to produce thickness A connection layer of 18 to 22 μm. The arithmetically averaged mean roughness measured according to DIN EN ISO 4287 at 3 different positions along the length of 2 pieces of connecting rods prior to processing of the original part was 0.62 μm Rz. The connecting rod was removed from the carbonitriding salt bath and oxidized in an oxidizing salt bath containing lithium at 430° C. for 45 minutes, wherein the melt consisted of:

[0121] NaNO 3 30 wt%, NaNO 2 2% by weight, NaOH 45% by weight, KOH 5% by weight, NaOH 2 CO 3 5% by weight, K 2...

Embodiment 3

[0124] Like embodiment (2), the length of 27cm and the diameter of 8mm connecting rods in the titanium crucible are made by material C35 made of 27 pieces as the connecting rods in the air spring. In the carbonitriding salt bath in the following according to the so-called Carbonitriding at 600°C + / - 5°C for 60 minutes under the process conditions of the method (cyanate content 37.5% by weight, cyanide content 4.2% by weight, iron content less than 200ppm) to produce thickness A connection layer of 18 to 22 μm. As in example (2), the arithmetically averaged average roughness measured according to DIN EN ISO 4287 at 3 different positions in the length direction of 2 connecting rods was 0.62 μm Rz before the original part was processed. The connecting rod was removed from the carbonitriding salt bath and oxidized at 430° C. for 45 minutes in an oxidizing lithium-containing salt bath having the following composition:

[0125] NaNO 3 30% by weight, NaNO 2 1 wt%, NaOH 40 wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com