Nonwoven fabric laminate and method and device for manufacturing same

A technology of spunbond non-woven fabrics, non-woven fabric layers, applied in the directions of lamination devices, textiles and papermaking, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

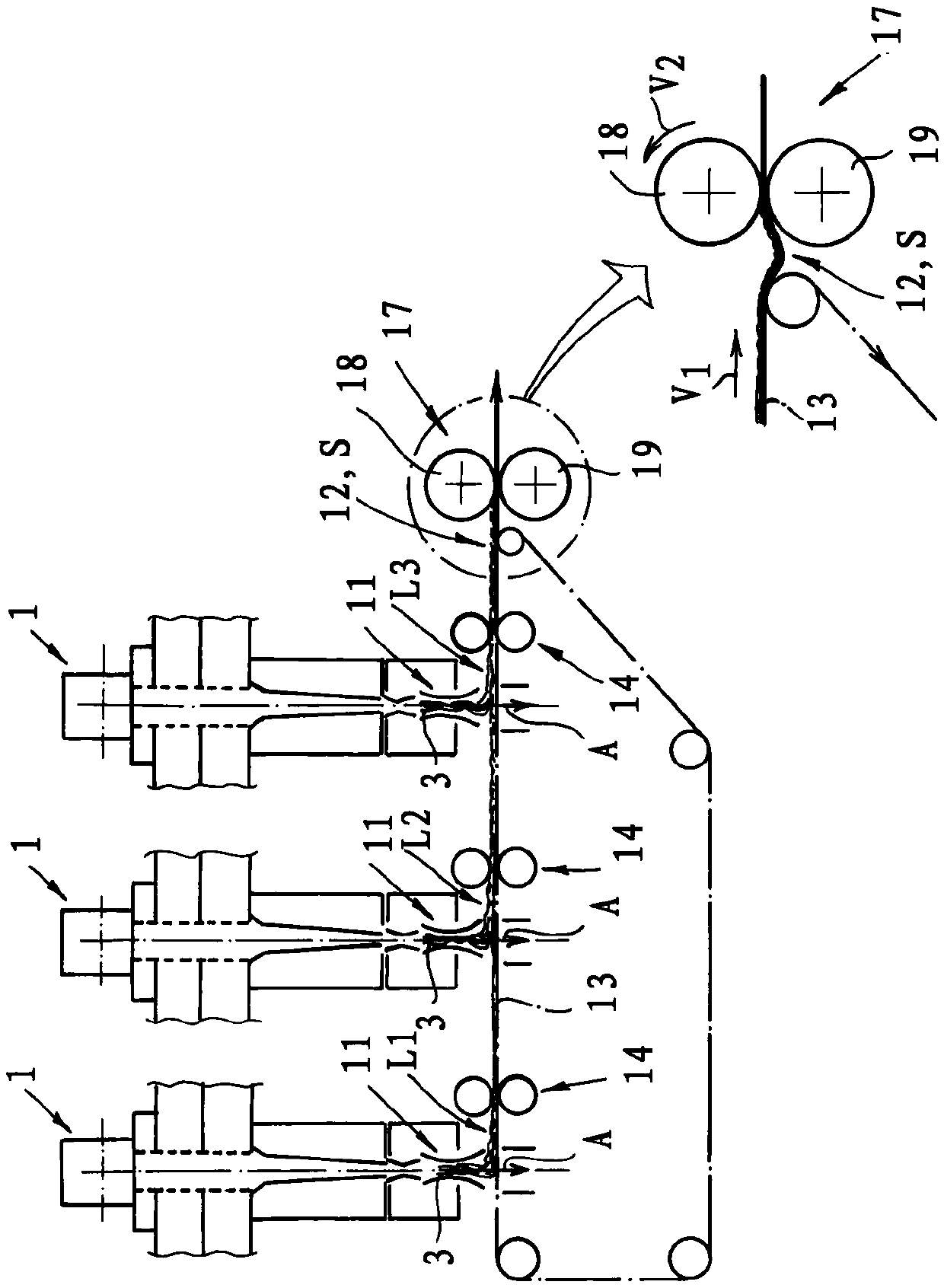

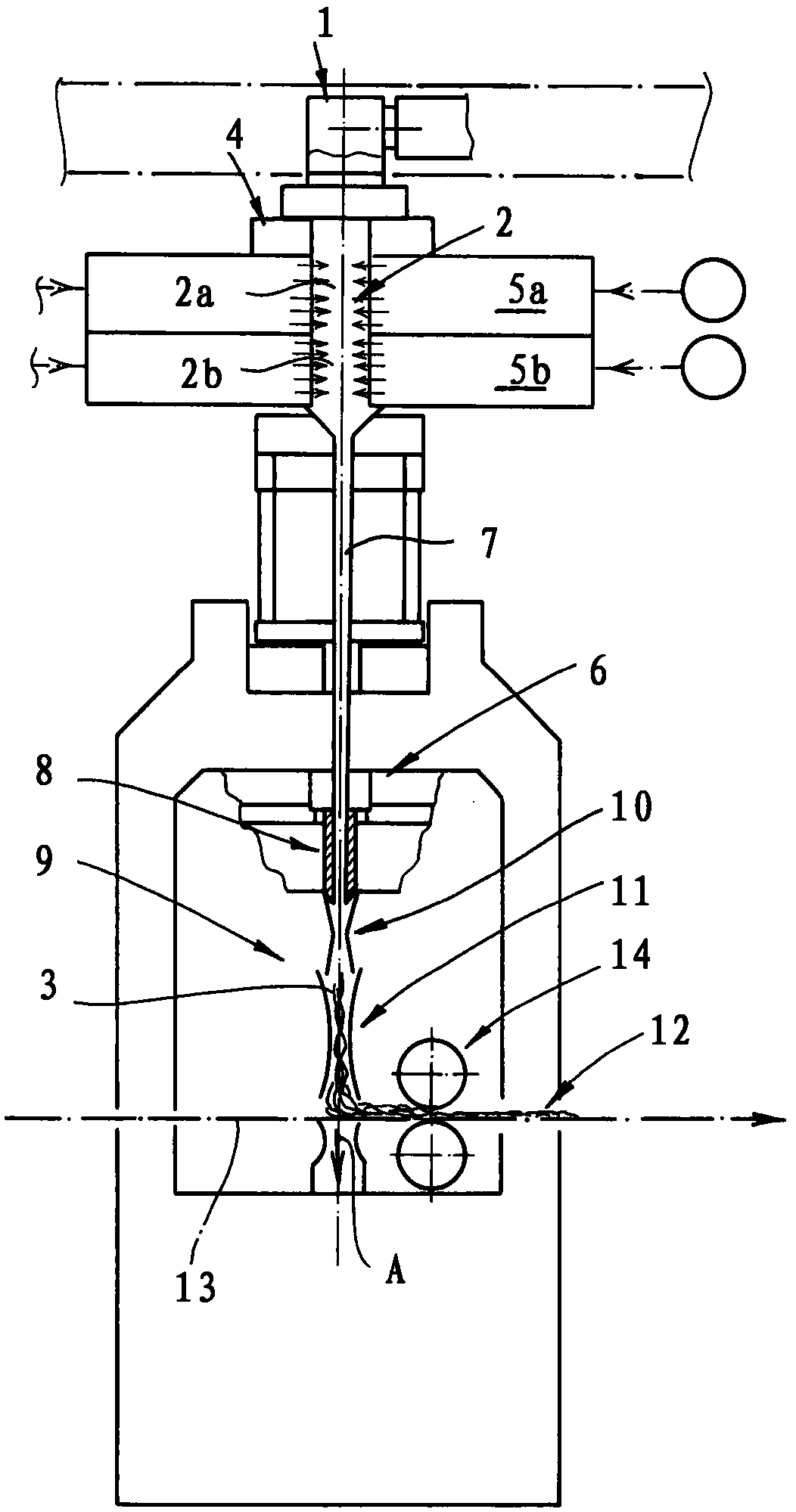

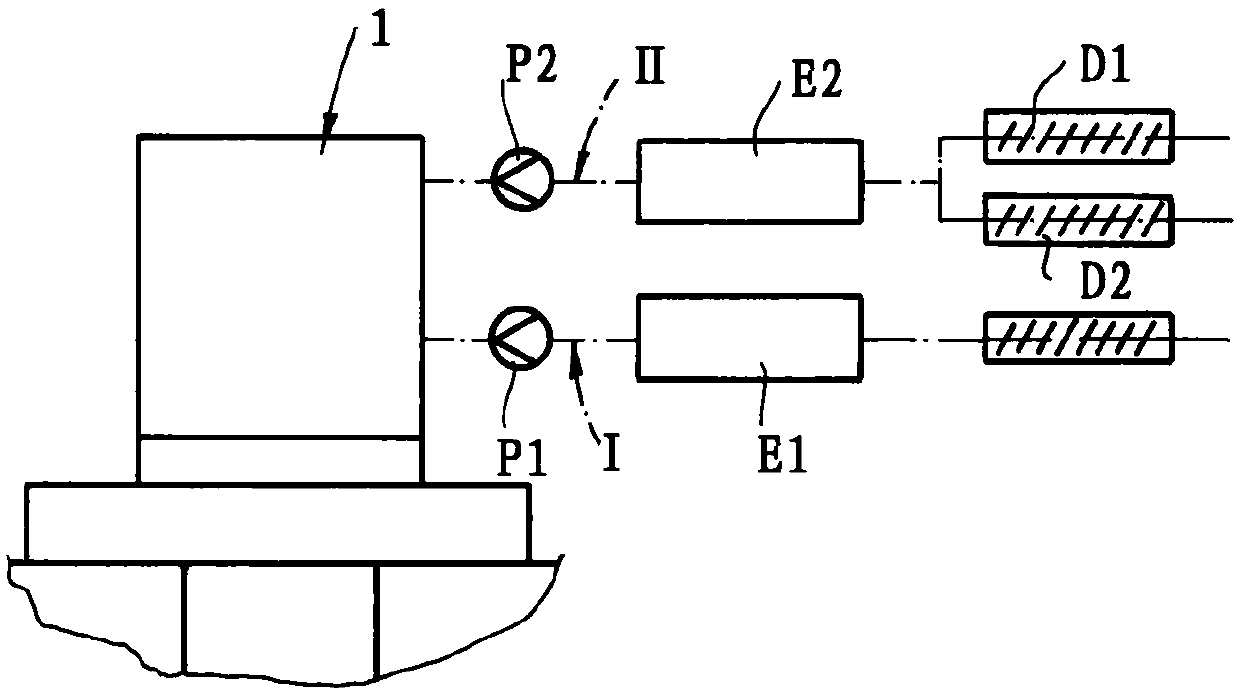

[0083] figure 1A device according to the invention for producing a spunbond nonwoven laminate S is shown, which preferably and in this example has three spunbond nonwoven layers L1, L2 and L3. Corresponding to the three spunbonded nonwoven layers L1, L2 and L3, three spinneret beams or spinneret plates 1 are arranged, from which spinneret beams, preferably and in this example, the bicomponent Filaments in filament form 3. After passing through the diffuser 11 , the filaments 3 of each spunbond nonwoven layer L1 , L2 and L3 are laid down on a laying screen 13 to form a spunbond nonwoven layer L1 , L2 and L3 . Here, each spunbond nonwoven layer L1 , L2 , L3 is compacted by a pair of compaction rollers 14 . Subsequently, the finished three-layer spunbond nonwoven laminate S is transferred by a laying screen 13 to a calender 17 consisting of two calender rolls 18 , 19 . figure 1 An enlarged detail of the transfer of the spunbond nonwoven laminate S from the laying screen bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com