Crimp for connecting wires

A technology for connecting wires and crimping parts, which is applied in the direction of connecting components, connections, and connections where permanent deformation acts, and can solve problems such as difficult cutting, bending or forming, inability to prevent deflection of crimping barrels, mechanical and electrical performance failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Before describing the embodiments of the present disclosure, basic knowledge forming the basis of the present disclosure is described. Based on the foregoing considerations, the inventors have conceived the following aspects of the present disclosure.

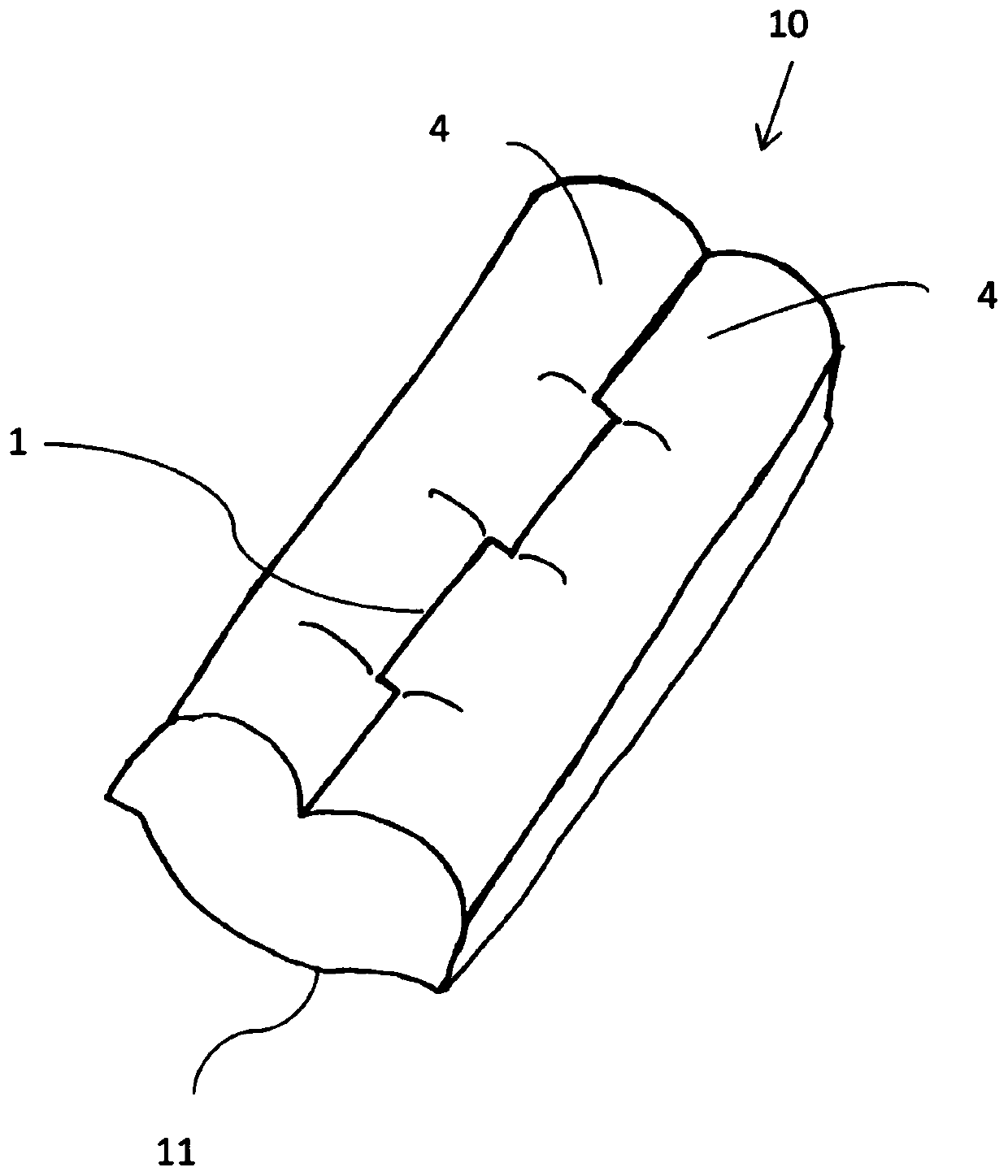

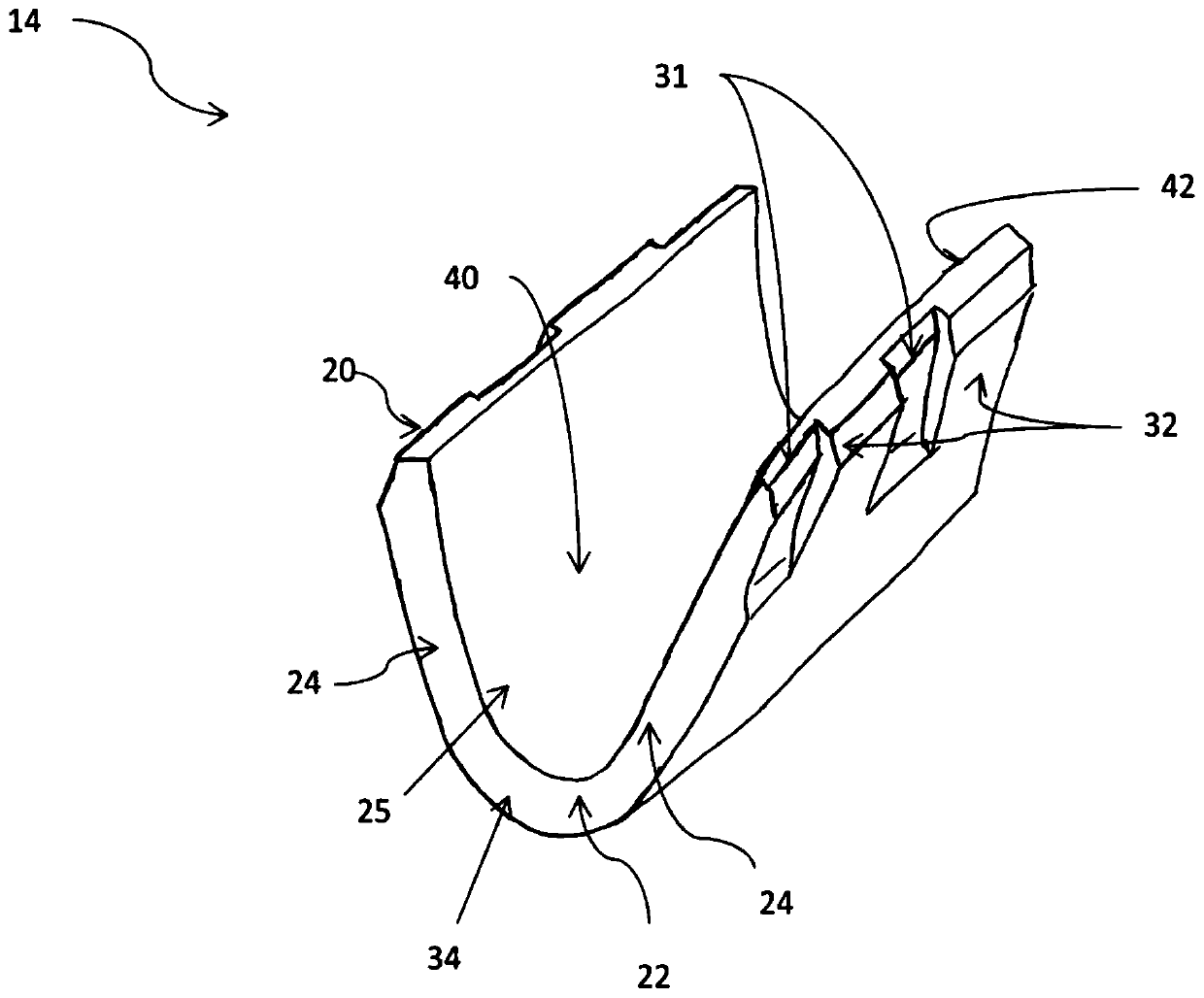

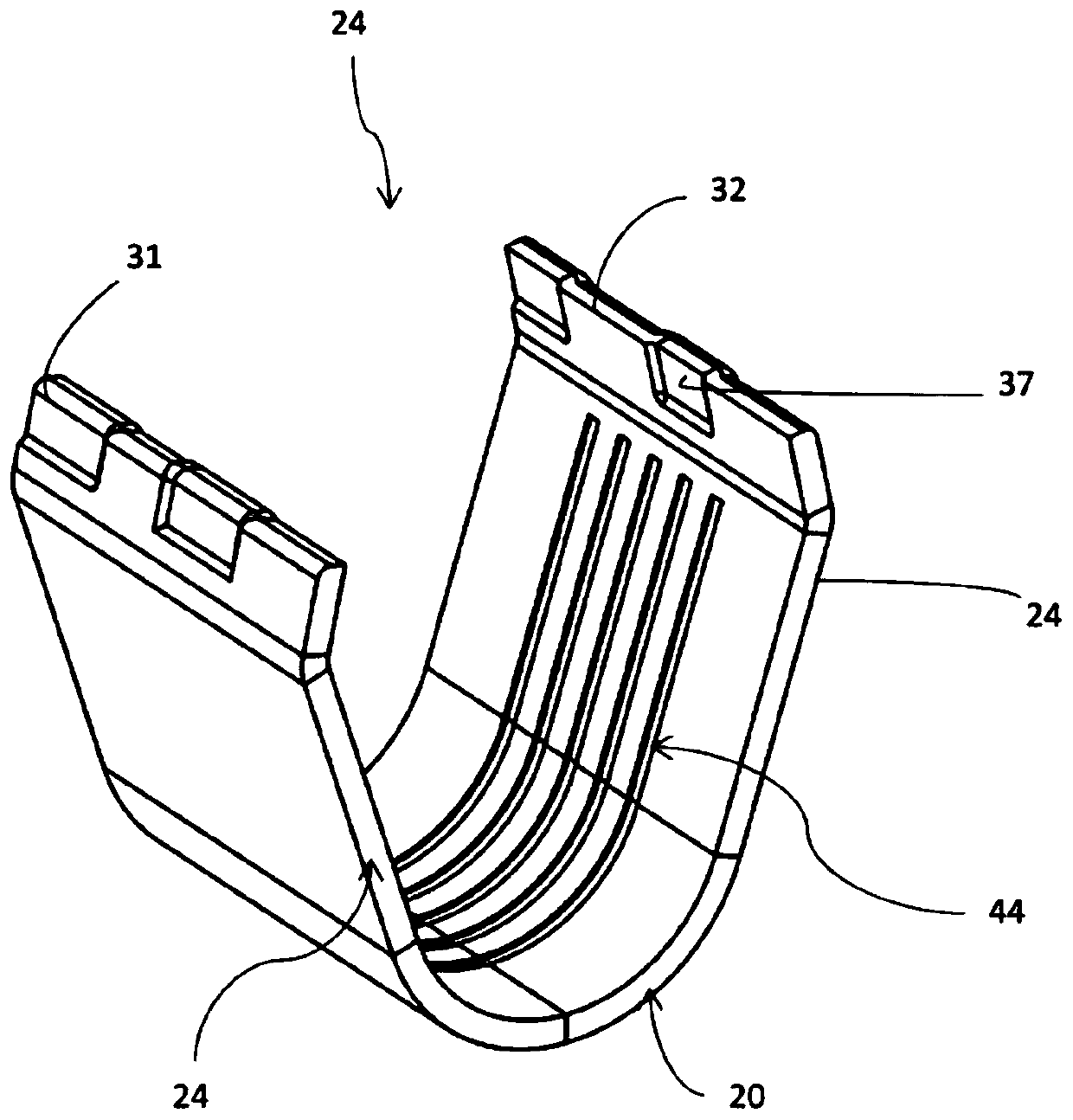

[0041] A crimp for connecting wires is provided, comprising at least one crimp barrel, wherein the crimp barrel includes at least one base and at least two opposing side walls extending from the base, wherein the side walls are adapted to bend around the wire such that The ends of the opposing side walls are joined to each other along a staggered seam.

[0042] This makes it possible to improve the locking of the seam against axial deformation of the sides and to produce additional snapping of the seam due to the axial elongation of the crimp that occurs in compression during crimp forming.

[0043] More specific examples of the present disclosure are described below. Note, however, that a detailed description may be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com