Tubular mould for molding concrete filled hollow thin wall component

A technology of hollow thin-walled molds, applied in the direction of molds, mold separation devices, etc., can solve the problems of easy damage of thin-walled tubes or thin-walled boxes, inconvenient demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

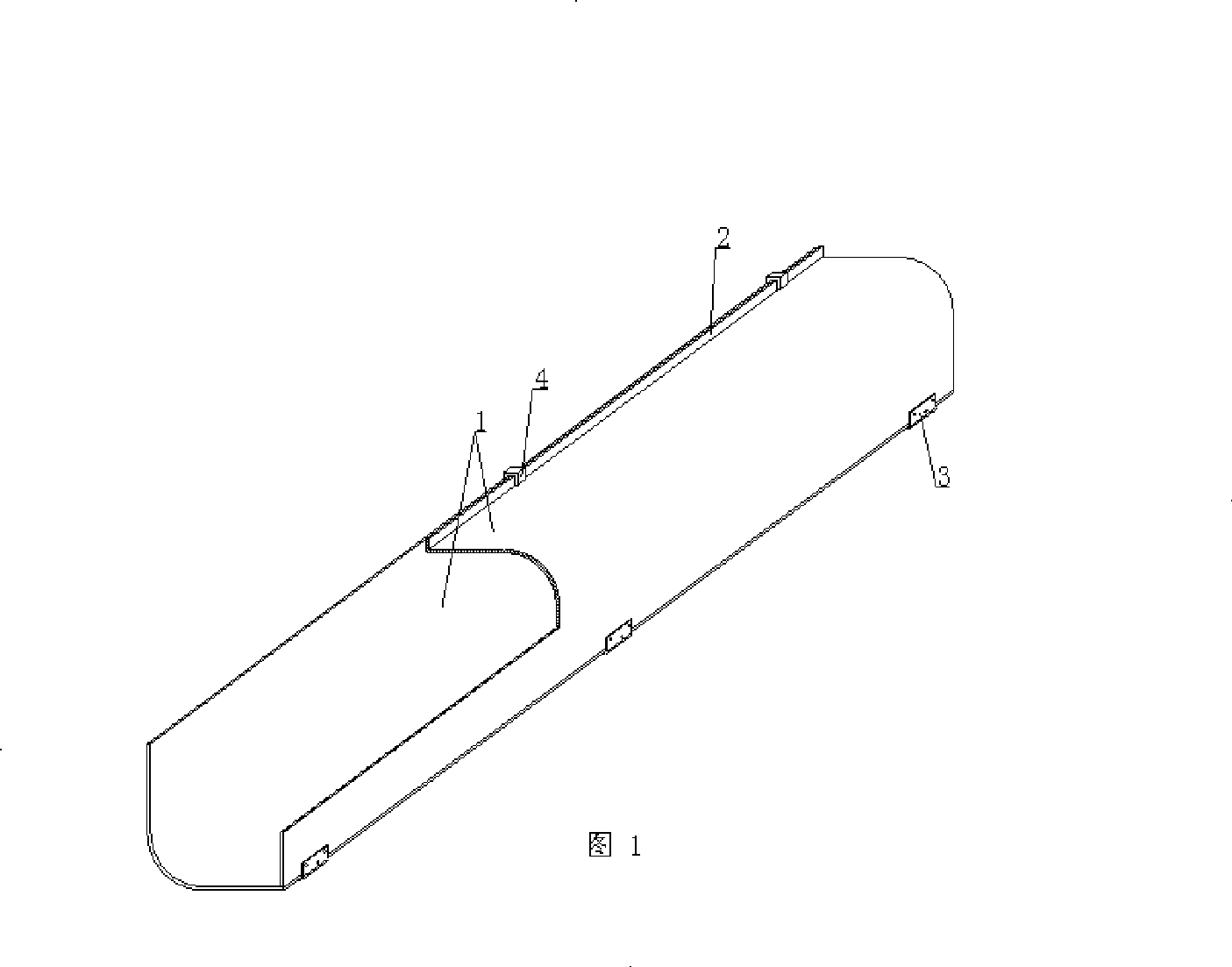

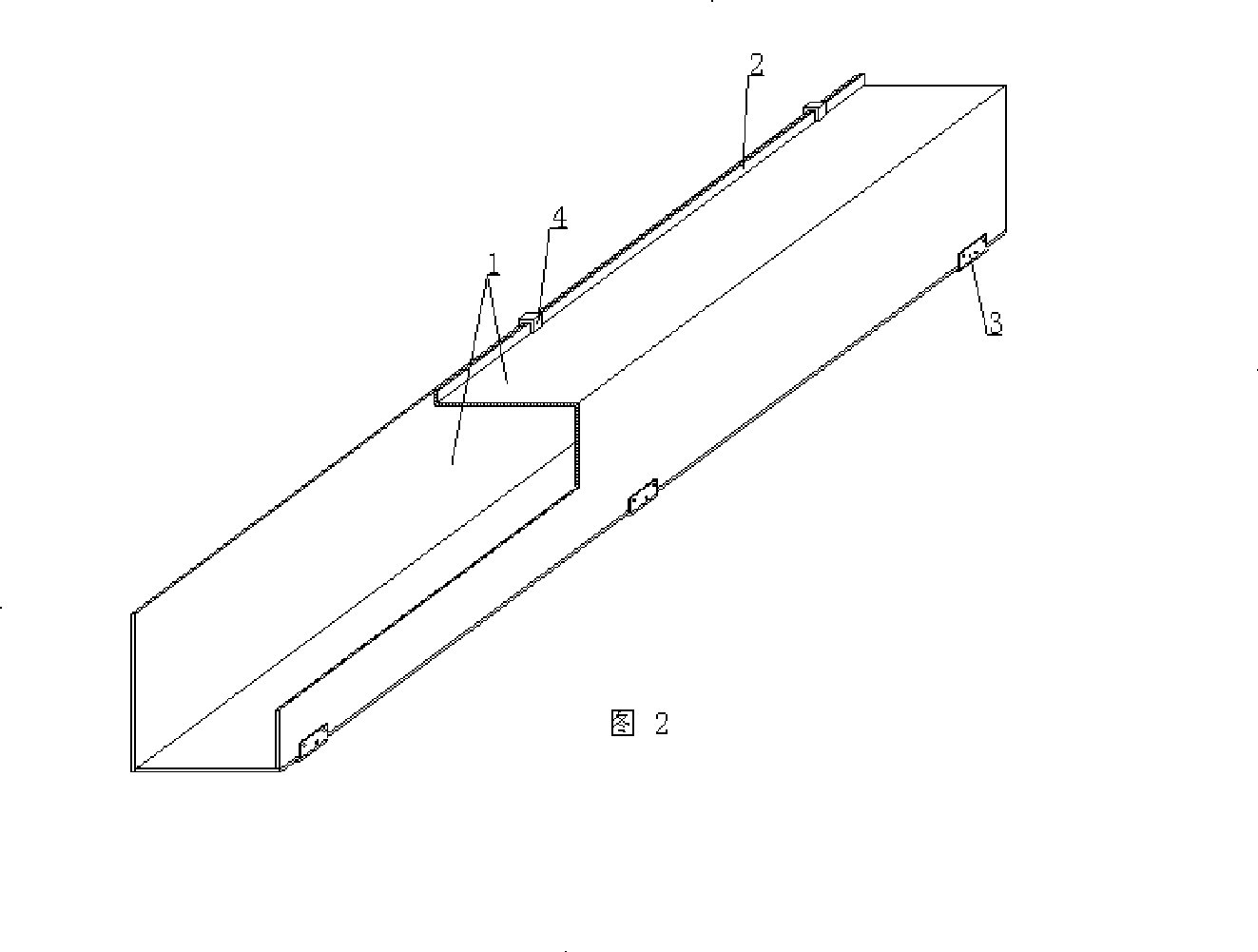

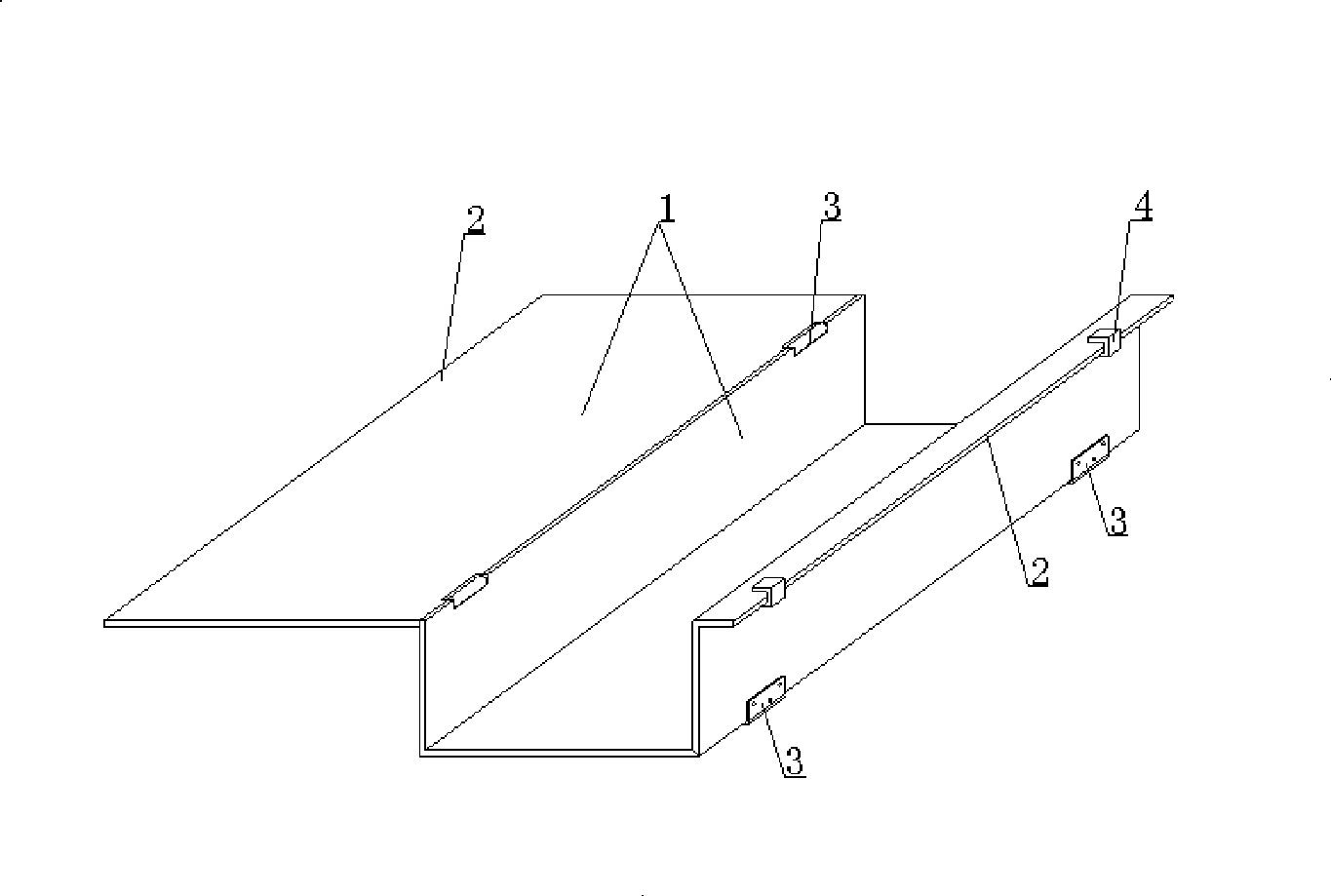

[0055] As shown in the drawings, the present invention includes at least two templates 1, joints 2, rotatable parts 3, and fasteners 4. The templates 1 are connected by rotatable parts 3, and the connected templates 1 can rotate relatively. The joints 2 is set on the template 1, and the fastener 4 closes and fixes the template 1 to form a cylindrical mold, which is characterized in that at least one template 1 is a non-planar curled or folded plate template, and a non-planar curled or folded plate The formwork 1 is U-shaped, and the U-shaped formwork 1 and the plate formwork 1 are closed to form a cylindrical mold. At least one end of at least one formwork in the formwork 1 is connected with an end formwork 1; or at least one formwork 1 is a non-planar curl or folded plate formwork, the non-planar curled or folded plate formwork 1 is U-shaped, two U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com