A copper pipe crimping device and crimping process for large-scale products

A crimping device and product technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of greater impact on production efficiency, inconvenient handling process, low production efficiency, etc., to improve production efficiency, easy assembly, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

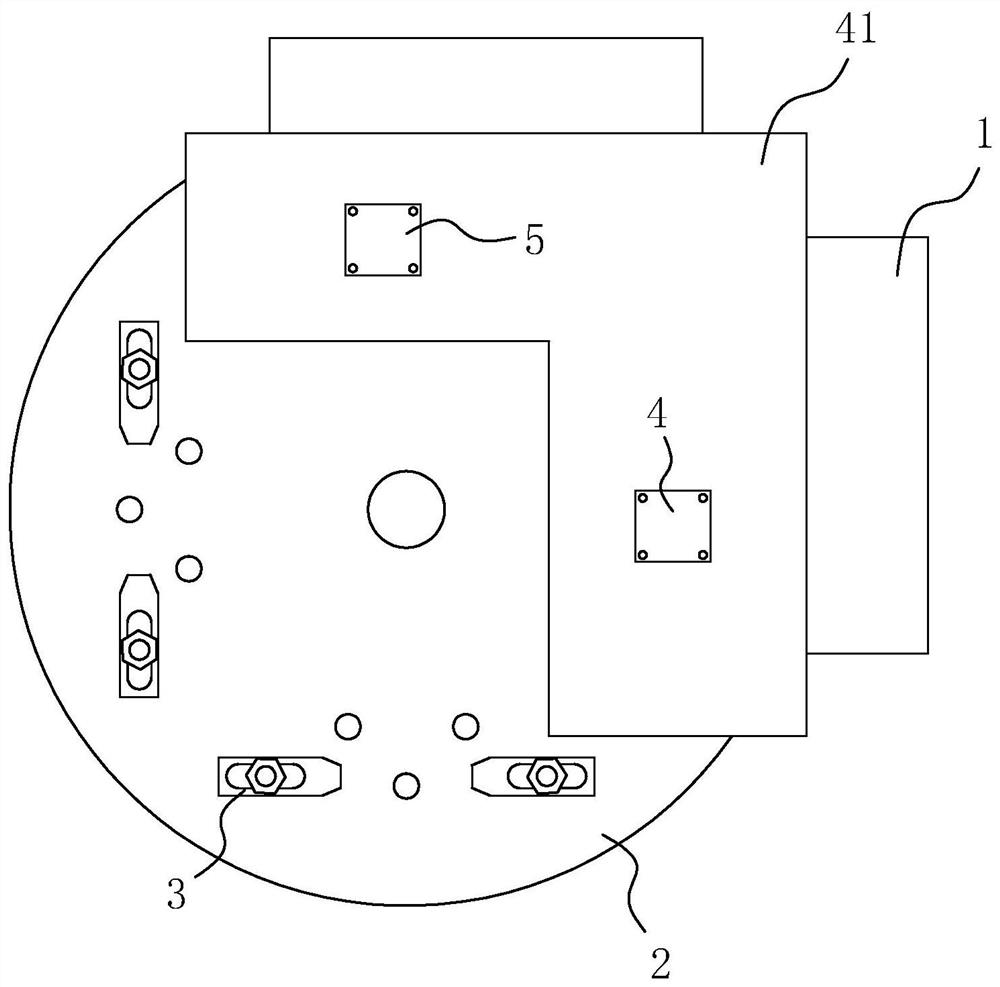

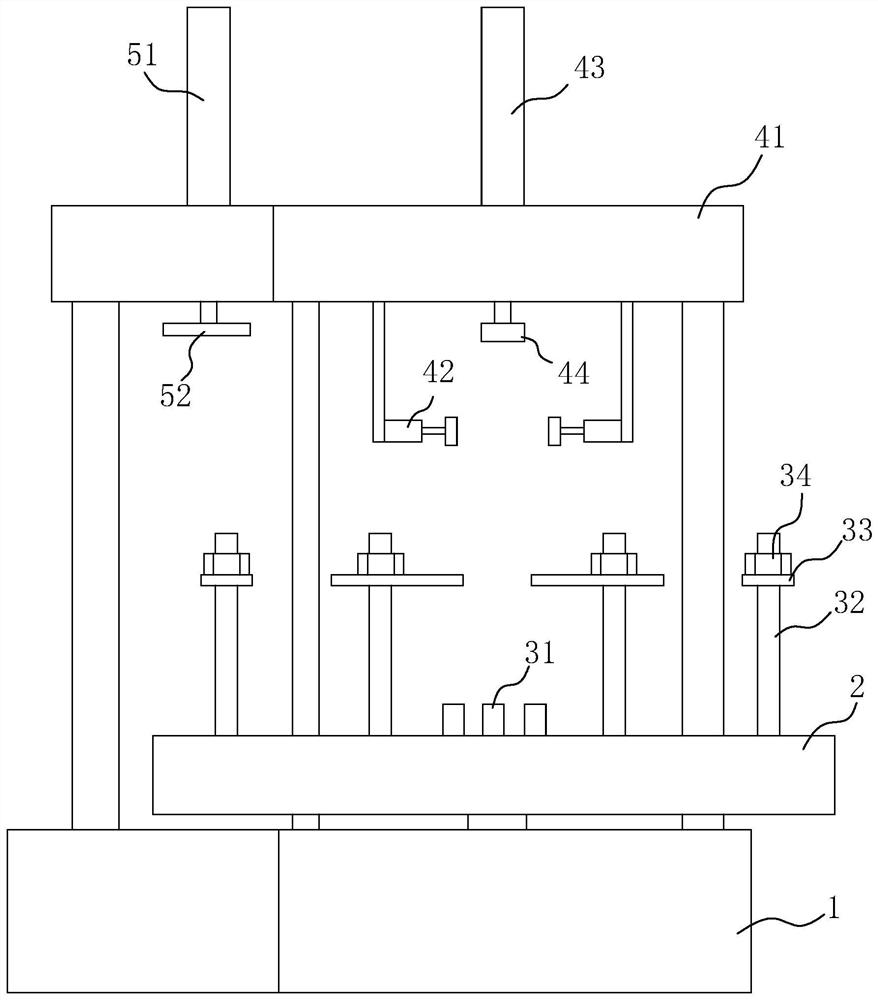

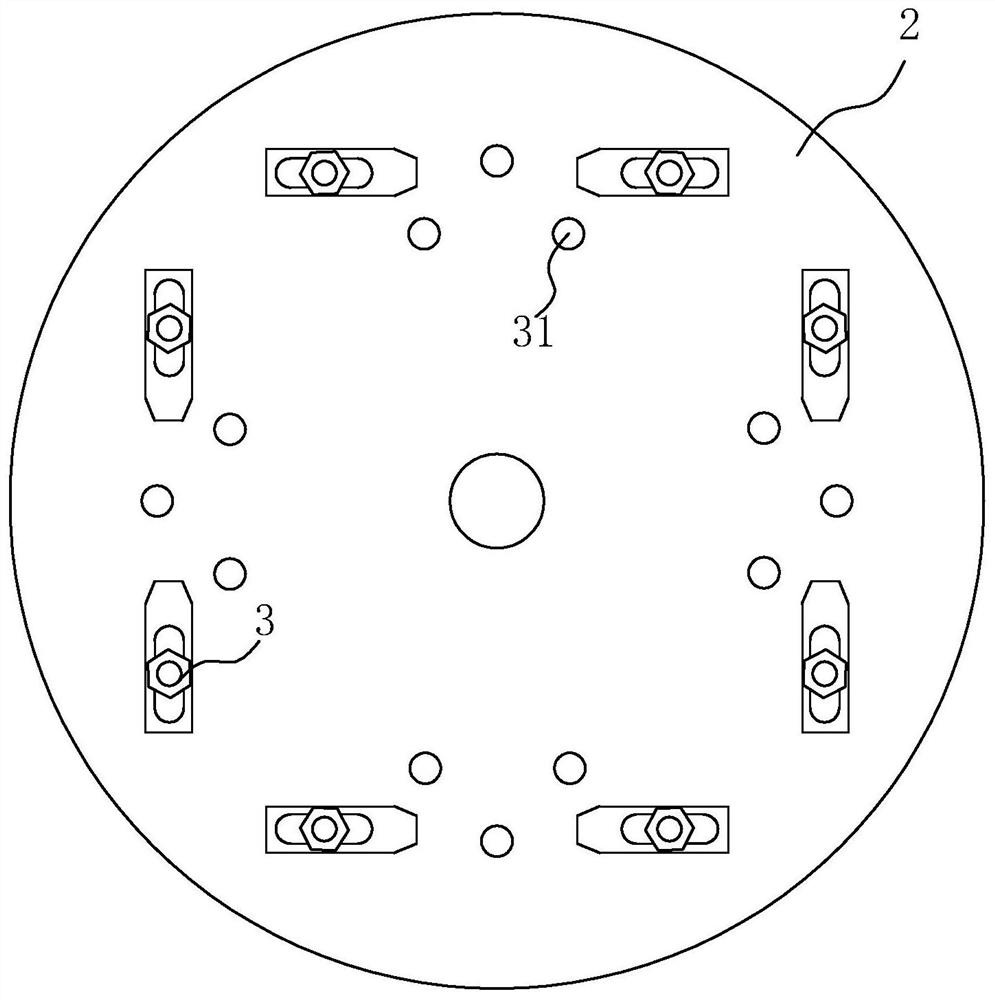

[0040] A large product copper tube crimping device such as figure 1 As shown, it includes: a machine platform 1; a supporting turntable 2 that is rotatably connected to the machine platform 1, a drive motor for driving the supporting turntable 2 to rotate is provided on the machine platform 1, and at least three assemblers are arranged on the supporting turntable 2. position, and each assembly station is equipped with a fixing mechanism 3 for fixing the product to be crimped; carried on the machine 1 for assembling the copper tube to be crimped and pre-pressing the copper tube to be crimped on the product to be crimped a pre-installation mechanism; and a pressing mechanism 5 carried on the press table 41 for press-fitting the copper tube to be crimped into the product to be crimped.

[0041] Specifically, such as figure 2 and image 3As shown, the driving motor (not shown in the figure) is fixed in the machine platform 1 by bolts, and the driving motor is a servo motor, the...

Embodiment 2

[0048] Based on the crimping device of Embodiment 1, this embodiment provides a copper tube crimping process for large-scale products, including:

[0049] Step 1: The product to be crimped is pre-installed on the support turntable 2 through the fixing mechanism 3, the copper tube to be crimped is clamped and fixed under the first hydraulic cylinder 43 by the clamping assembly 42, and the upper end of the copper tube to be crimped The clip is embedded in the pressing sleeve 44, so that the copper pipe to be crimped is in a vertical state, and the clamping assembly 42 will be clamped by it.

[0050] Step 2: The supporting turntable 2 is driven to rotate by driving the motor, and the product to be crimped is moved directly under the pre-installation mechanism.

[0051] Step 3: The first hydraulic cylinder 43 drives the copper tube to be crimped to press down to pre-press and fix the copper tube to be crimped on the product to be crimped. The depth of the crimped copper tube is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com