Fitting for connecting to a tubular element and tubing connection

A technology of connectors and pipe shapes, which is applied in the direction of pipes/pipe joints/fittings, pipe joints, pipe elements, etc., and can solve the problem that the connection force is not enough to ensure reliable fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

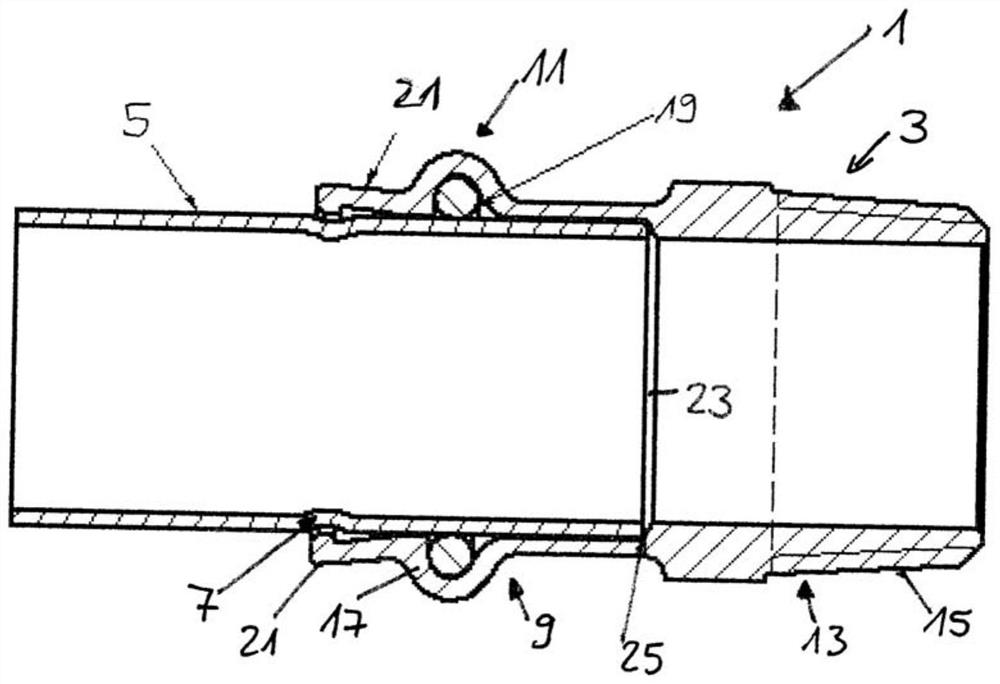

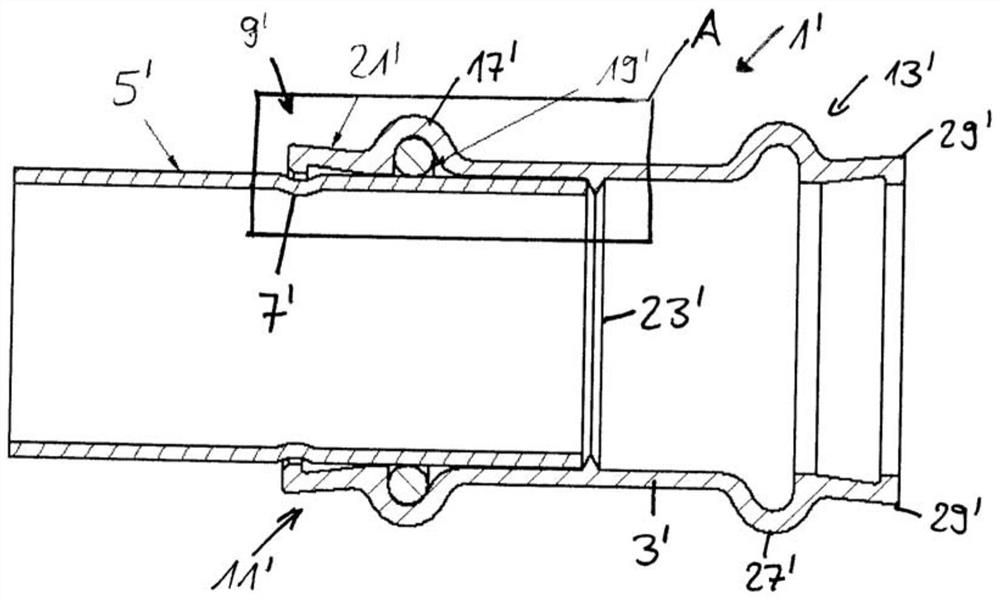

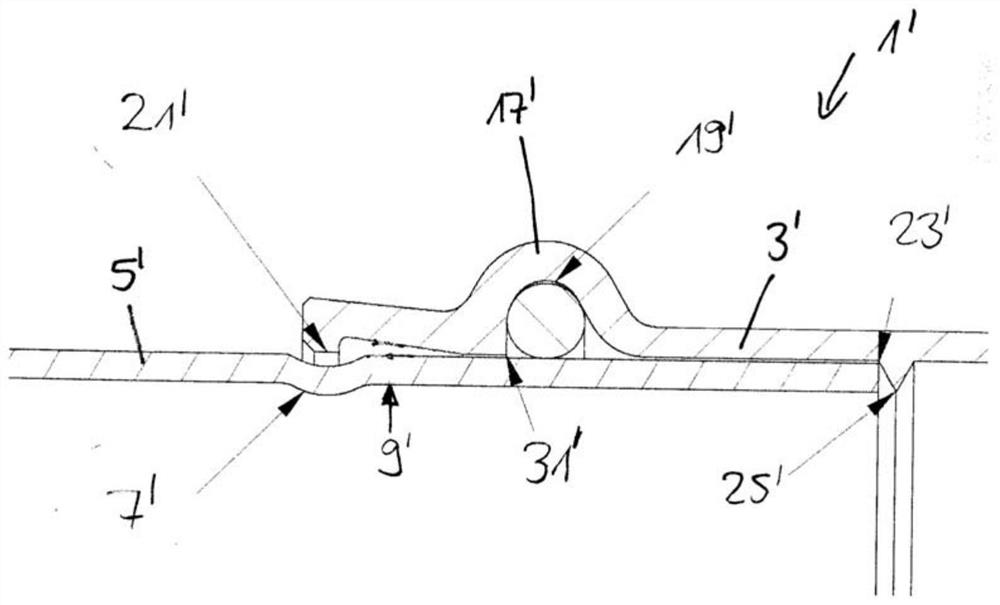

[0068] figure 1 A cross-sectional view of a pipe connection according to the first aspect of the invention is shown. The line connection 1 comprises a connection 3 and a tubular piece 5 . like figure 1 As shown, the tubular element 5 comprises a crimping element 7 so that a second crimping element is formed on the outer surface of said tubular element in the sense of the claims.

[0069] The wall thickness of the tubular part 5 is constant over the entire length of the tubular part 5 , in particular in the region of the crimping part 7 . The joint 3 comprises a first section 5 comprising a first connecting piece 11 . Furthermore, the joint 3 comprises a second end section 13 comprising a second connecting piece in the form of a thread 15 .

[0070] Furthermore, in the region of the end section 9 an annular groove 17 is provided in which a first seal in the form of an O-ring 19 is arranged. According to the invention, the first connecting element 11 comprises a hook 21 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com