Method of alumyte flotation removing quartz

A bauxite and flotation technology, applied in flotation, solid separation, etc., can solve difficult problems, achieve low chemical consumption, simple process flow, and increase the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

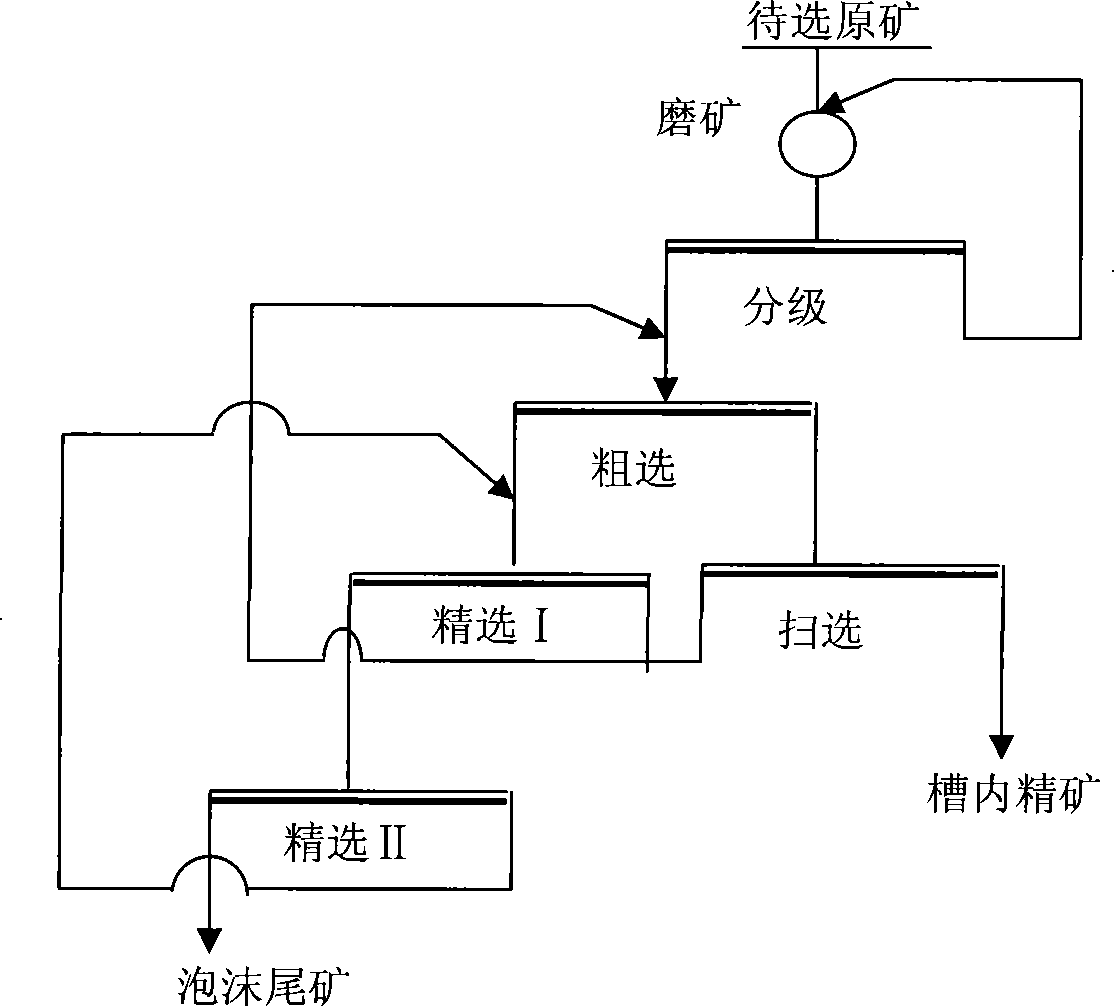

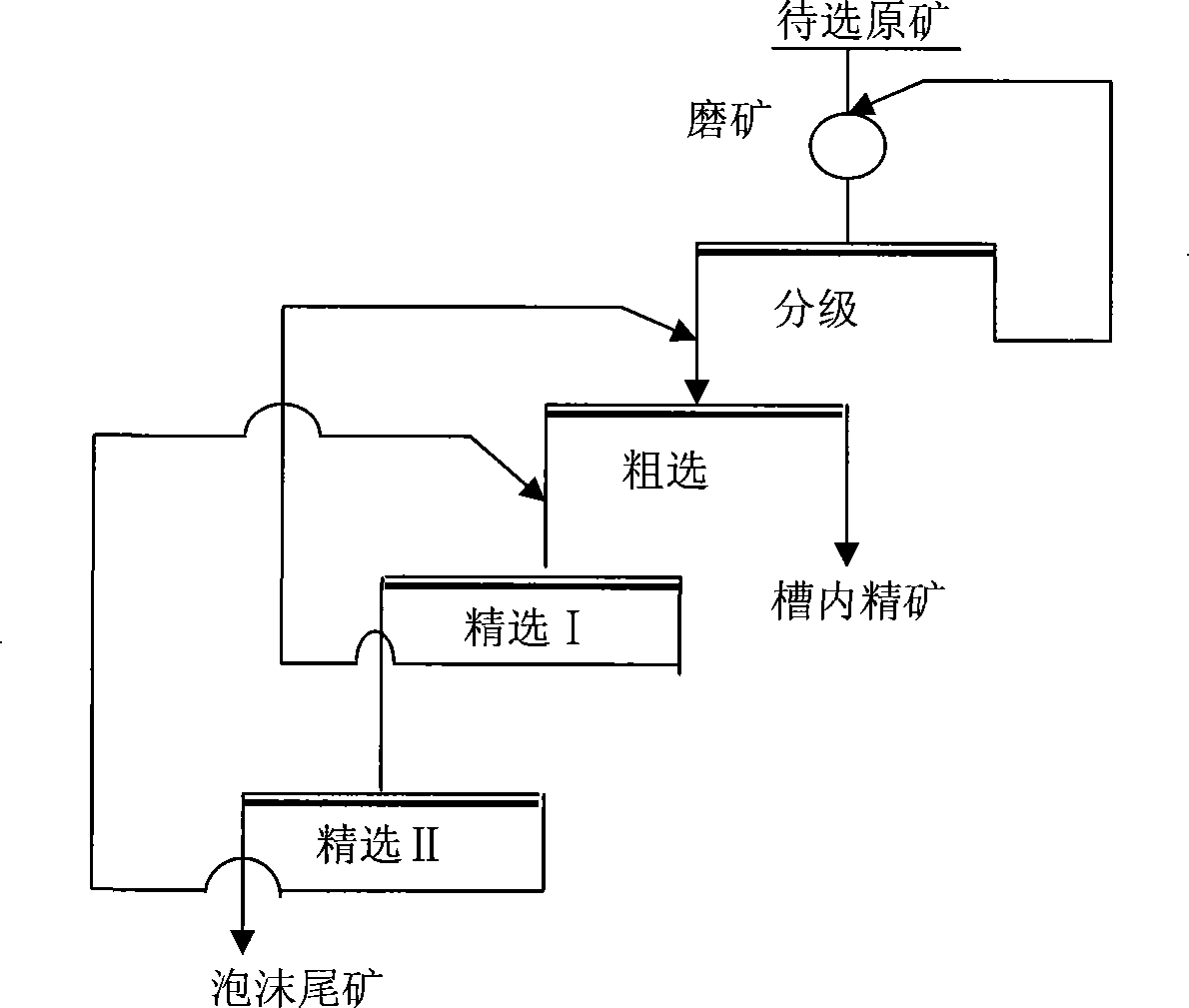

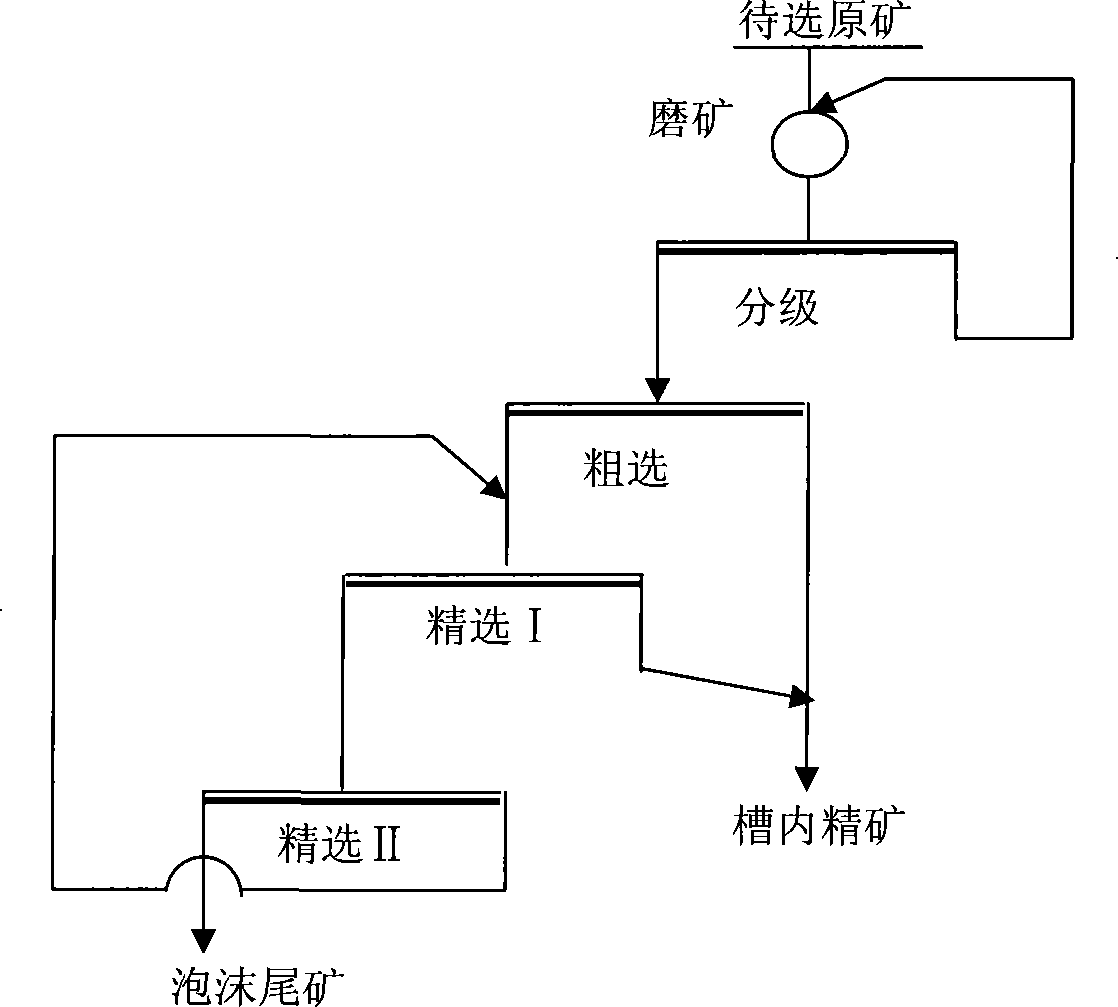

[0022] A method for removing quartz by bauxite flotation is based on the particle size distribution characteristics of quartz-containing mineral particles in gibbsite-type bauxite containing boehmite and the physical and chemical properties of each mineral, by selecting The permanent grinding technology enables efficient dissociation of useful minerals such as gibbsite and boehmite and gangue mineral quartz. When the grinding fineness is -0.074mm and accounts for 30% to 100%, the floating The weight percent concentration of the dressing pulp is 5%-28%. When the pH value is 8.5-11, one or more kinds of phosphate or carboxylate-containing salts are used, and the dosage is 100-4000g / t-raw ore regulator , using one or more of amines or their modified products as collectors, when the amount of collectors is 50-1500g / t-raw ore, add a small amount of collectors to the flotation pulp through multiple dispersions To keep the collector concentration of the flotation system at 1×10 -5 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com