Ion-aluminum separation technique of high-alumina brown iron ore

A high-alumina limonite and limonite technology, applied in the direction of improving process efficiency, can solve the problems of difficulty in realizing monomer dissociation and inability to effectively separate iron and aluminum, and achieve increased specific surface area and improved reactivity , Improve the effect of iron grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

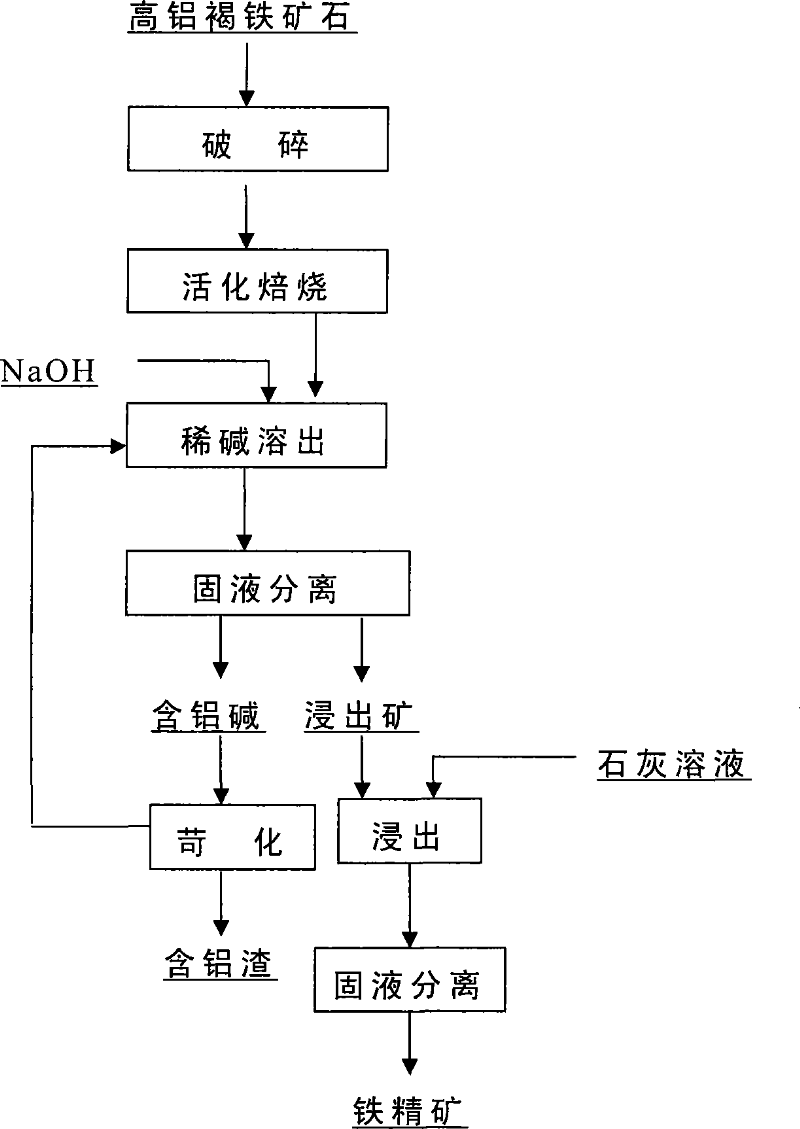

Embodiment 1

[0011] Embodiment 1: see accompanying drawing, TFe content 52.62%, Al 2 o 3 Limonite ore with a content of 6.23%, crushed to a particle size of less than 1.0mm, roasted at 400°C for 20 minutes, and then placed in a reactor at 150°C, with 100g / L NaOH solution according to the mass liquid-solid ratio L / S =4 / 1 for leaching and dealumination, the leaching time is 35min, after the solid-liquid separation, the filtrate is returned to utilization through causticizing, and the filter cake is reacted with the lime solution at 100°C for 50min, and then the solid-liquid separation, the solid is iron Concentrate, can make the content of TFe in iron concentrate reach 63.20%, Al 2 o 3 The content is 2.6%, Na 2 The O content is 0.19%.

Embodiment 2

[0012] Embodiment 2: see accompanying drawing, TFe content 45.69%, Al 2 o 3 Limonite ore with a content of 8.76%, crushed to a particle size of less than 1.0mm, roasted at a temperature of 450°C for 18 minutes, and then placed in a reactor at 140°C, with 135g / L NaOH solution according to the mass liquid-solid ratio L / S =6 / 1 for leaching and dealumination, the leaching time is 20min, after the solid-liquid separation, the filtrate is returned to utilization through causticization, and the filter cake is reacted with the lime solution at 120°C for 40min, after solid-liquid separation, the solid is iron Concentrate, can make the content of TFe in iron concentrate reach 59.28%, Al 2 o 3 The content is 2.5%, Na 2 The O content is 0.2%.

Embodiment 3

[0013] Embodiment 3: see accompanying drawing, TFe content 48.23%, Al 2 o 3 Limonite ore with a content of 10.95%, crushed to less than 1.0mm, roasted at a temperature of 500°C for 10 minutes, and then placed in a reactor at a temperature of 120°C, with 150g / L NaOH solution according to the mass liquid-solid ratio L / S=3 / 1 for leaching dealumination, the leaching time is 45min, after the solid-liquid separation, the filtrate is returned to utilization through causticization, and the filter cake is reacted with the lime solution at 140°C for 30min, and then the solid-liquid separation, the solid is Iron concentrate can make the content of TFe in iron concentrate reach 61.5%, Al 2 o 3 The content is 3.0%, Na 2 The O content is 0.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com