Preparation method of high heat-resistant boehmite

A boehmite, high heat-resistant technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of lower qualification rate of electronic substrates, foaming of synthetic resin, uneven surface, etc., to achieve widened applications, high oil absorption rate, High whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preparation method of high heat-resistant boehmite comprises the following steps:

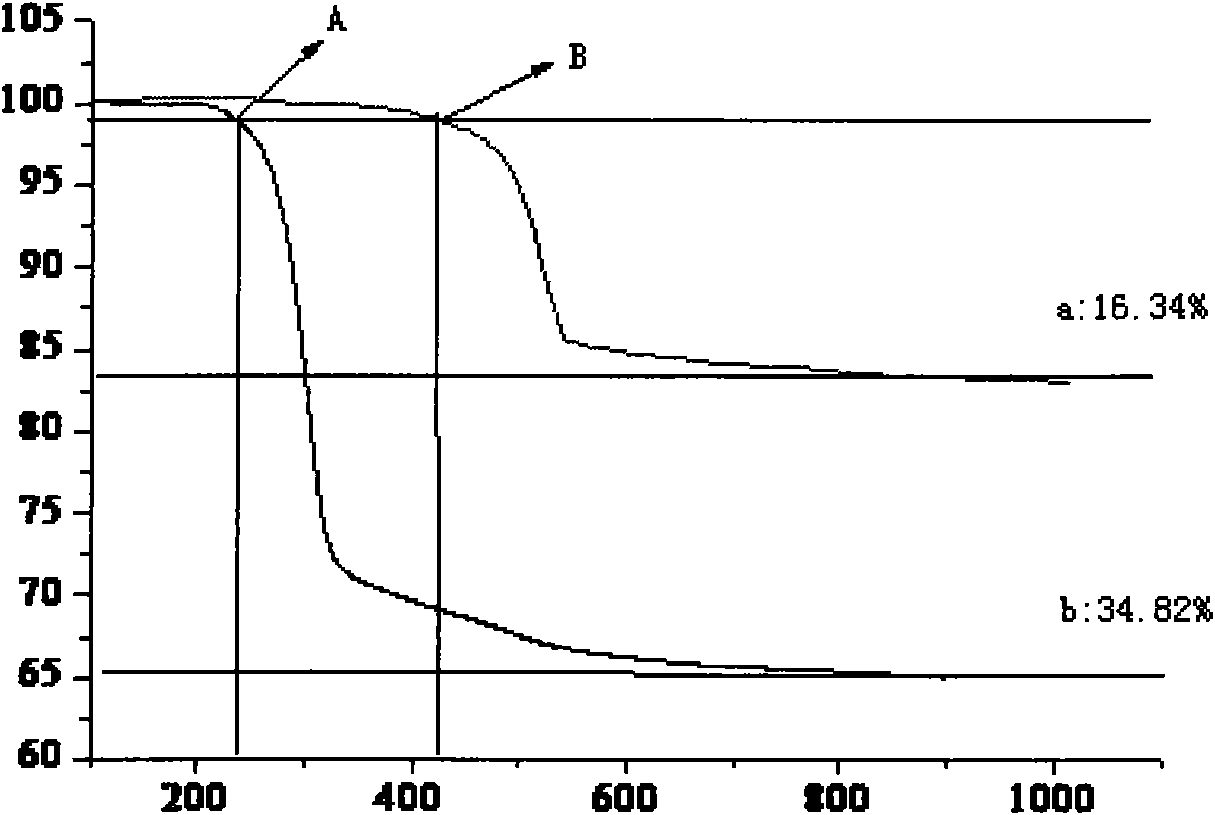

[0020] (1) Put the aluminum hydroxide of 1 μm under the conditions of temperature ≥ 350°C and pressure ≥ 10kPa until the gibbsite crystal structure of aluminum hydroxide is converted into boehmite, and the dehydration amount is greater than 16% ;

[0021] (2) Grind the boehmite to a particle size of 50-400 nanometers, then evenly disperse the boehmite particles into the water, use a wet high-speed stirring method to disperse the boehmite, and perform nano-SiO on the surface 2 Coating treatment, while controlling the pH value of the slurry within the range of 6.8-7.2;

[0022] (3) The product boehmite is obtained by drying after impurity removal and purification.

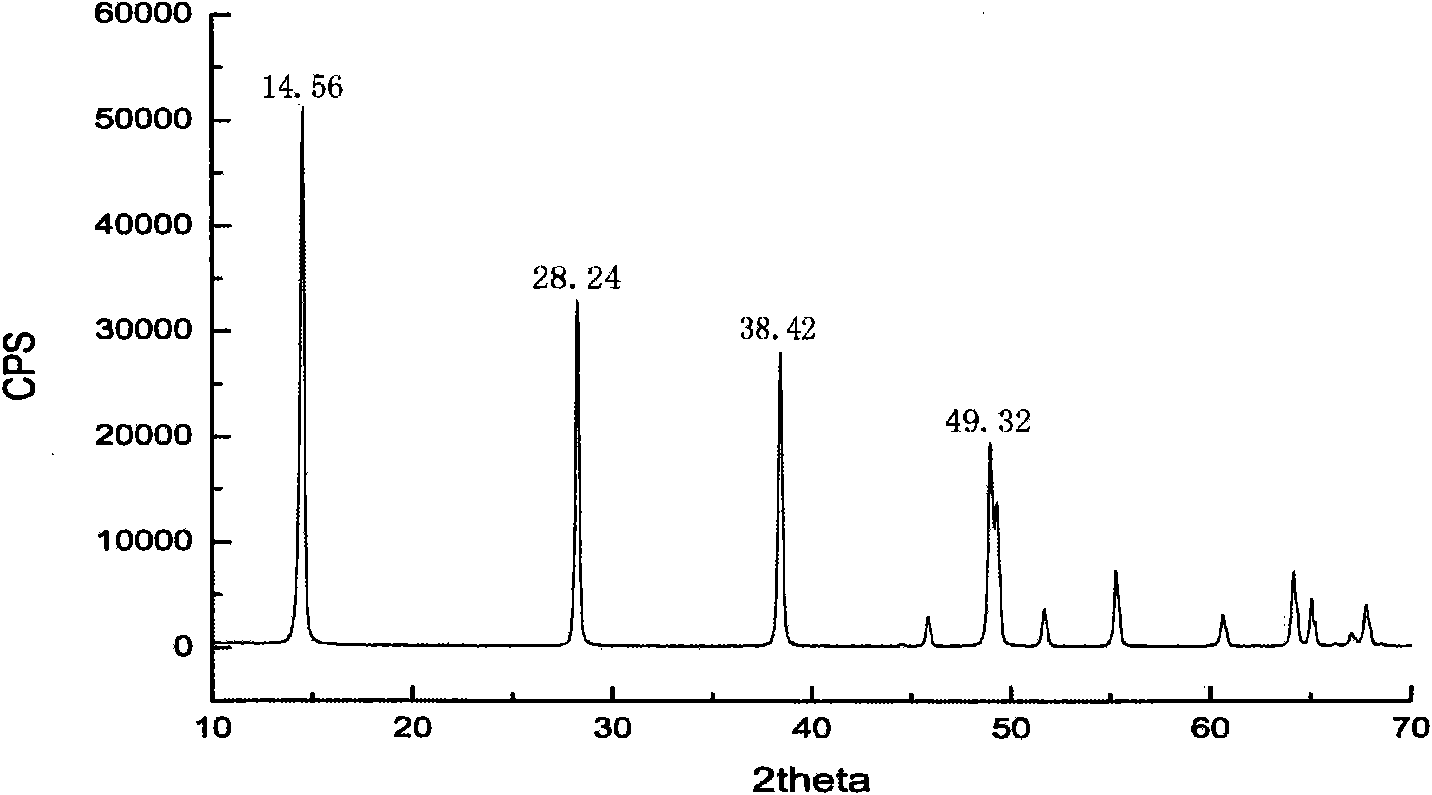

[0023] In this embodiment, 1 μm aluminum hydroxide is used as raw material, and the 1% dehydration temperature of the aluminum hydroxide raw material is 235° C., and the 1% dehydration temperature of the boehmite product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com