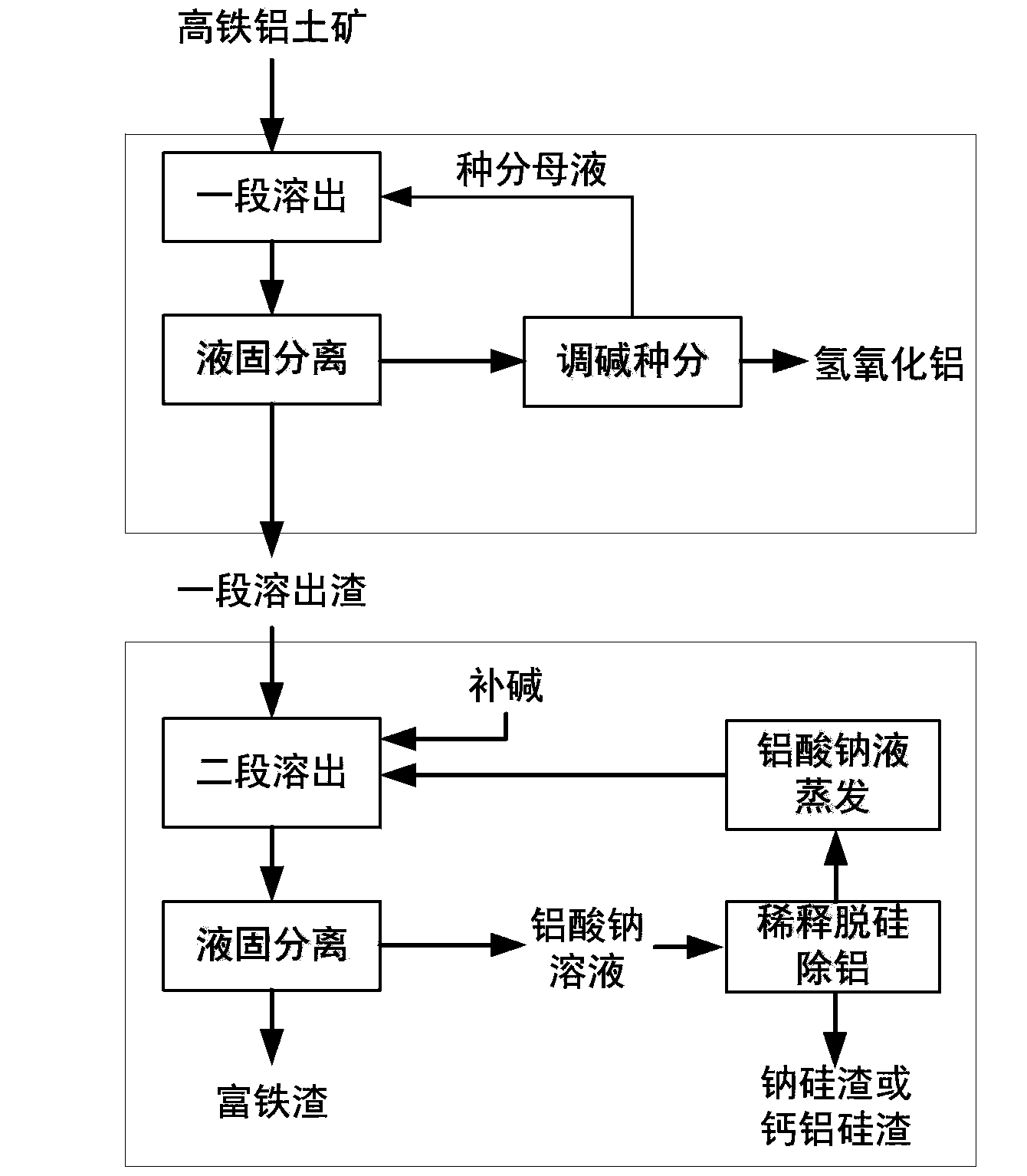

Method for extracting aluminum and iron from high iron gibbsite-type bauxite

A technology for gibbsite-type bauxite, which is applied in the field of extraction of aluminum and iron from high-iron gibbsite-type bauxite, which can solve the problems of high energy consumption and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

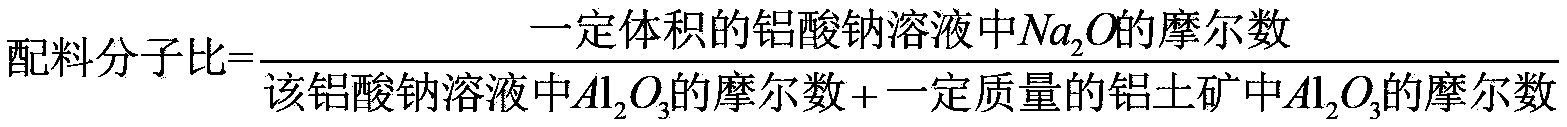

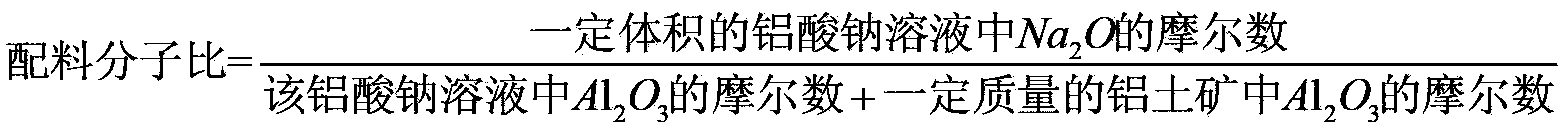

Embodiment 1

[0030] Configure Na 2 Sodium aluminate solution with an O concentration of 100g / L and a molecular ratio of 3.0, mix the high-iron gibbsite ore with the sodium aluminate solution according to the liquid-solid ratio (volume mass ratio 7:1), and the molecular ratio of the ingredients is 1.47 at this time. The mixed slurry was reacted at 100°C for 60 minutes, and the liquid-solid separation was carried out while the reaction was hot, and the resulting eluate directly entered the seeding process to extract aluminum hydroxide without adjusting the alkali concentration; configure Na 2 O concentration 300g / L, the sodium aluminate solution of molecular ratio 1.6, one section stripping slag is mixed with this sodium aluminate solution by liquid-solid ratio 20, and mixed slurry is placed in autoclave at 260 ℃ of reaction 1h, After the reaction is completed, liquid-solid separation is carried out while hot to obtain Fe 2 o 3 Iron-rich slag with a content of up to 80.45%, dilute the seco...

Embodiment 2

[0032] Configure Na 2 Sodium aluminate solution with an O concentration of 250g / L and a molecular ratio of 4.0, mix the high-iron gibbsite ore with the sodium aluminate solution according to the liquid-solid ratio (volume-to-mass ratio) of 3:1. At this time, the molecular ratio of the ingredients is 1.74. The mixed slurry was reacted at 130°C for 20min, and the liquid-solid separation was carried out while the reaction was hot, and the obtained one-stage eluate was adjusted to Na 2 After the O concentration is below 180g / L, enter the sorting process to extract aluminum hydroxide; configure Na 2 O concentration 400g / L, the sodium aluminate solution of molecular ratio 60, one section stripping slag is mixed with this sodium aluminate solution by liquid-solid ratio 15, and mixed slurry is placed in autoclave at 300 ℃ of reaction 2h, After the reaction is completed, liquid-solid separation is carried out while hot to obtain Fe 2 o 3 Iron-rich slag with a content as high as 87.3...

Embodiment 3

[0034] Configure Na 2 Sodium aluminate solution with an O concentration of 150g / L and a molecular ratio of 2.0, mix the high iron gibbsite ore with the sodium aluminate solution according to the liquid-solid ratio (volume-to-mass ratio) of 10:1. At this time, the molecular ratio of the ingredients is 1.51. The mixed slurry was reacted at 90°C for 120min, and the liquid-solid separation was carried out while the reaction was hot, and the resulting eluate directly entered the seeding process to extract aluminum hydroxide without adjusting the alkali concentration; configure Na 2 Pure NaOH solution with an O concentration of 300g / L (molecular ratio is infinite), mix a section of the leached slag with the lye at a liquid-solid ratio of 18, and place the mixed slurry in an autoclave at 350°C for 4 hours, and the reaction is over After that, liquid-solid separation was carried out while hot to obtain Fe 2 o 3 Iron-rich slag with a content of up to 85.40%; dilute the second-stage e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com