Process for producing gama-alumina microsphere

A production method, alumina technology, applied in chemical instruments and methods, alumina/hydroxide preparation, inorganic chemistry, etc., can solve the problems of affecting the catalytic effect of microspheres, low pore volume of microspheres, increasing costs, etc., to achieve It is conducive to the promotion and application of industrialization, the production cost is low, and the effect of improving production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

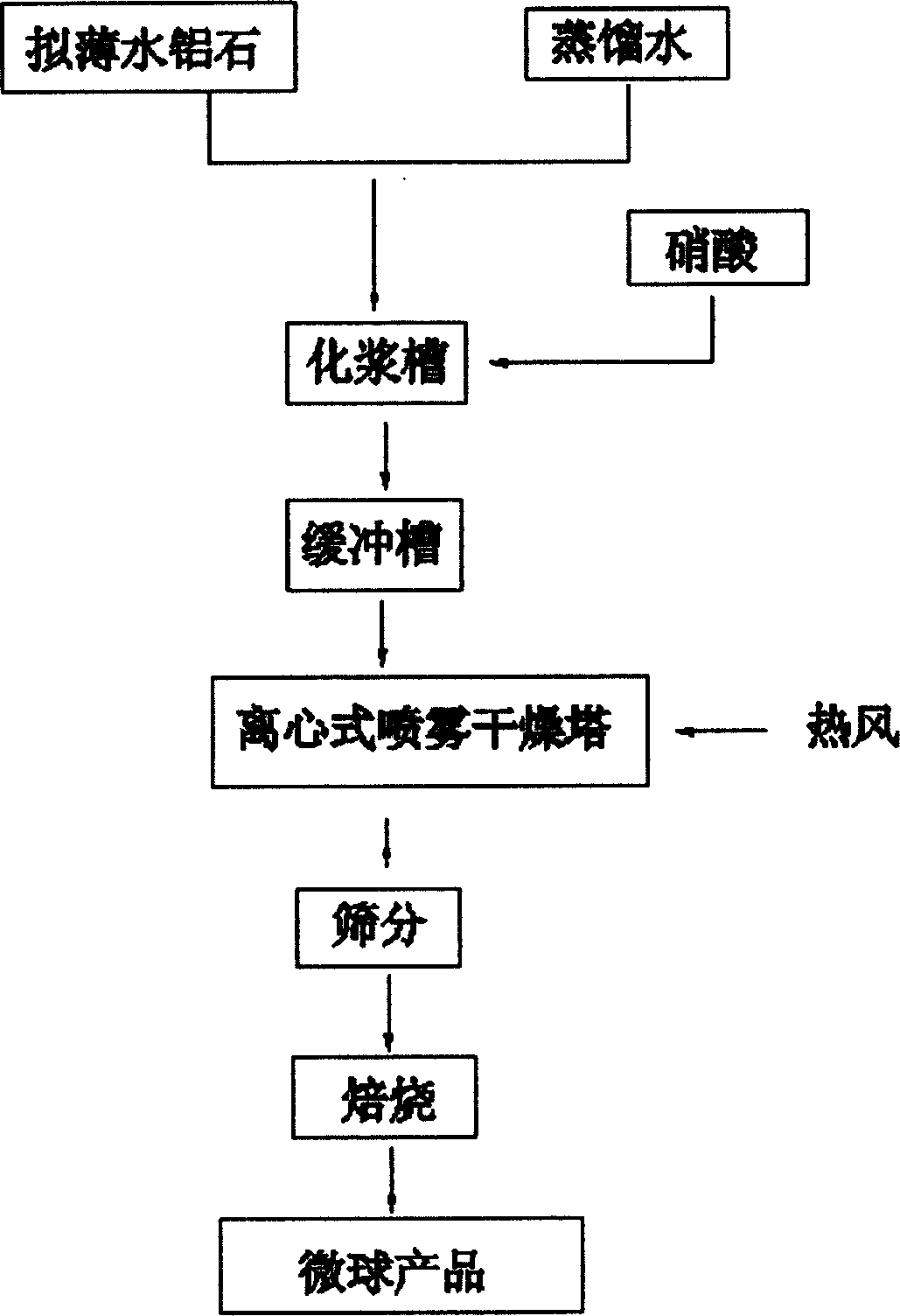

Image

Examples

Embodiment 1

[0020] The production method of gamma-alumina microspheres described in the present invention is formed by reacting pseudo-boehmite and nitric acid into a gel, formed by centrifugal spray drying, and then roasted, wherein:

[0021] The concentration of nitric acid used is controlled to be 65%, the addition of nitric acid accounts for 5% of the pseudo-boehmite weight, and the liquid-solid weight ratio of the gelling reaction is controlled to be 3;

[0022] The gelling temperature is 50±1°C, and the gelling time is 4 hours;

[0023] The firing temperature is 800±10°C, and the firing time is 2 hours.

Embodiment 2

[0025] The production method of gamma-alumina microspheres described in the present invention is formed by reacting pseudo-boehmite and nitric acid into a gel, formed by centrifugal spray drying, and then roasted, wherein:

[0026] The concentration of nitric acid used is controlled to be 60%, the addition of nitric acid accounts for 8% of the pseudo-boehmite weight, and the liquid-solid weight ratio of the gelling reaction is controlled to be 4;

[0027] The gelling temperature is 50±1°C, and the gelling time is 3 hours;

[0028] The firing temperature is 600±10°C, and the firing time is 3 hours.

Embodiment 3

[0030] The production method of gamma-alumina microspheres described in the present invention is formed by reacting pseudo-boehmite and nitric acid into a gel, formed by centrifugal spray drying, and then roasted, wherein:

[0031] The concentration of nitric acid used is controlled to be 70%, the addition of nitric acid accounts for 2% of the weight of pseudo-boehmite, and the liquid-solid weight ratio of the gelling reaction is controlled to be 5;

[0032] The gelling temperature is 60±2°C, and the gelling time is 2 hours;

[0033] The firing temperature is 800±15°C, and the firing time is 1.8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com