Alpha-alumina carrier and preparation method thereof

A technology of alumina carrier and alumina water, which is applied in the field of catalysis, can solve the problems of increasing the pore volume and pore diameter of alumina, and achieve the effect of ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 255.00g gibbsite, 169.00g pseudo-alumina monohydrate, 75.00g ammonium fluoride, 1.00g barium sulfate, put them into the mixer and mix for 15min to obtain a solid powder mixture, then add dilute nitric acid (nitric acid: water = 1:3, weight ratio), transfer the mixture to a kneader for 20 minutes, knead and cut into seven-hole columns on a molding machine, dry the columns at 30°C for 45 hours, and then The pillars were calcined at a temperature of 1300° C. for 20 h at a constant temperature, and finally cooled to room temperature.

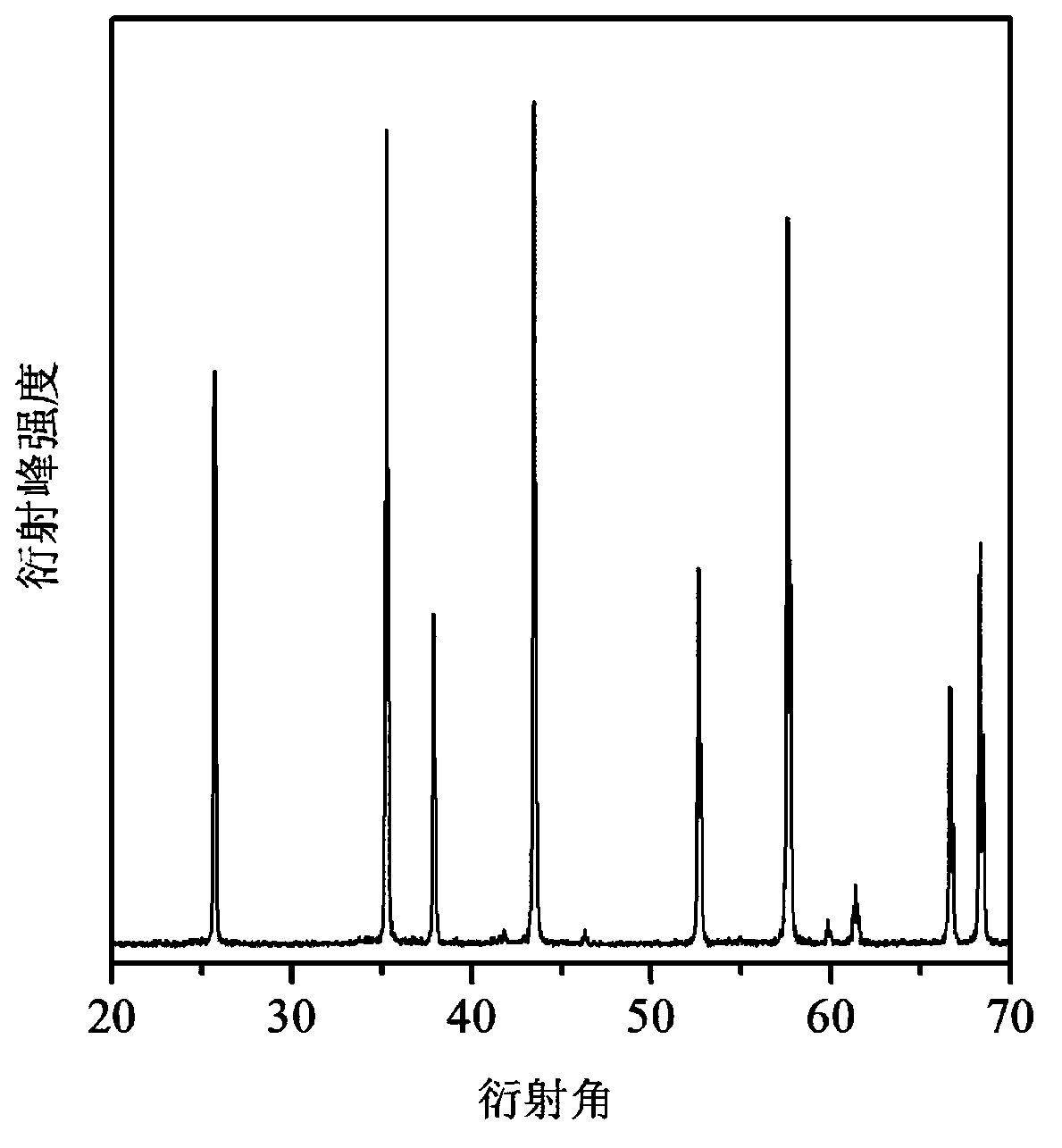

[0022] X-ray diffraction analysis results show that the product is α-alumina, and its XRD pattern is as follows figure 1 shown. The most probable pore size of the α-alumina support is 9.03 μm as measured by a mercury intrusion tester. The BET specific surface area of the α-alumina carrier measured by the specific surface-pore size distribution analyzer is 0.18m 2 / g.

Embodiment 2

[0024] Weigh 313.79g gibbsite, 116.22g pseudo-alumina monohydrate, 50.00g magnesium fluoride, 20.00g magnesium chloride, put them into a mixer and mix for 50min to obtain a solid powdery mixture, then add dilute nitric acid ( Nitric acid: water = 1:8, weight ratio), transfer the mixture to a kneader for 50 minutes, knead and cut into five-hole columns on a molding machine, dry the columns at 90°C for 45 hours, and then knead The pillars were calcined at a temperature of 1550° C. for 10 hours at a constant temperature, and finally cooled to room temperature.

[0025] The results of X-ray diffraction analysis indicated that the product was α-alumina. The most probable pore size of the α-alumina support is 7.76 μm as measured by a mercury intrusion tester. The BET specific surface area of the α-alumina carrier measured by the specific surface-pore size distribution analyzer is 0.32m2 / g.

Embodiment 3

[0027] Weigh 363.91g gibbsite, 101.09g pseudo-alumina monohydrate, 25.00g magnesium fluoride, 10.00g barium sulfate, put them into the mixer and mix for 40min to obtain a solid powder mixture, then add dilute nitric acid (nitric acid: water = 1:5, weight ratio), transfer the mixture to a kneader for 30 minutes, cut into single-hole columns on a molding machine after kneading, dry the columns at 80°C for 30 hours, and then The pillars were calcined at a temperature of 1200° C. for 30 hours at a constant temperature, and finally cooled to room temperature.

[0028] The results of X-ray diffraction analysis indicated that the product was α-alumina. The most probable pore size of the α-alumina support is 3.46 μm as measured by a mercury intrusion tester. The BET specific surface area of the α-alumina carrier measured by the specific surface-pore size distribution analyzer is 1.09m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Most probable aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bet specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com