Molten salt furnace pouring material and preparation method thereof

A castable and molten salt furnace technology, applied in the field of refractory materials, can solve problems such as wasting energy and affecting normal production, and achieve the effects of avoiding abnormal looseness, high reliability, and excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

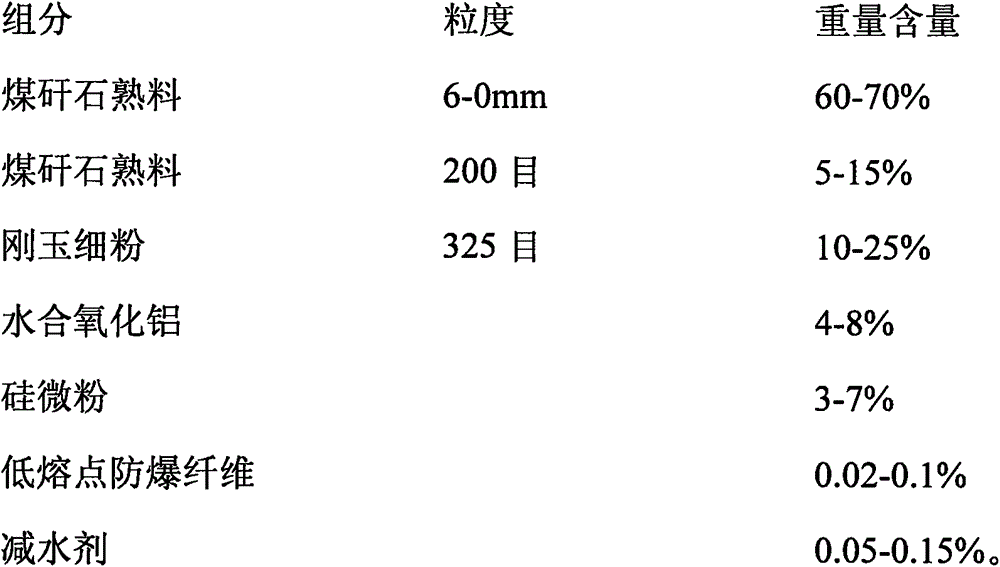

[0027] Castable formula for molten salt furnace:

[0028] Component particle size weight content

[0029] Coal gangue clinker 6-0mm65%

[0030] Coal gangue clinker 200 mesh 10%

[0031] Tabular corundum fine powder 325 mesh 15%

[0032] Hydrated alumina 5%

[0034] Low melting point explosion-proof fiber 0.05%

[0035] CASTAMENTFS 200.10%.

[0036] The manufacturing method of this embodiment includes the following steps:

[0037] The first step: raw material preparation and inspection; purchase raw materials according to technical standards, and inspect raw materials according to national standards, and then put them into use only after they are qualified;

[0038] The second step: preparation process of coal gangue clinker particles, using jaw crusher and counter-roll crusher to make coal gangue clinker into the required particle size;

[0039] The third step: magnetic separation and iron removal process, using super-strong magnetic separator to carry out strong mag...

Embodiment 2

[0051] Castable formula for molten salt furnace:

[0052] Component particle size weight content

[0053] Coal gangue clinker 6-0mm65%

[0054] Coal gangue clinker 200 mesh 10%

[0055] Fused white corundum fine powder 325 mesh 15%

[0056] Hydrated alumina 5%

[0058] Low melting point explosion-proof fiber 0.05%

[0059] CASTAMENTFS 200.10%.

[0060] The manufacturing method of this embodiment is the same as that of embodiment 1.

[0061] The main physical and chemical indexes of molten salt furnace castables in this embodiment are:

[0062] Chemical composition: Al 2 O 3 54.3%, SiO 2 44.6%, Fe 2 O 3 0.25%;

[0063] Matrix mineral phase composition: After firing at 1400℃, the matrix XRD results show that the main crystal phase is mullite;

[0064] Thermal shock resistance: The number of thermal shocks is 45.

[0065] CO corrosion resistance: The test standard adopts the American "Test Method for Disintegration of Refractories in CO Atmosphere" (ASTMC288). The test ...

Embodiment 3

[0067] Castable formula for molten salt furnace:

[0068] Component particle size weight content

[0069] Coal gangue clinker 6-0mm65%

[0070] Tabular corundum fine powder 325 mesh 24%

[0071] Hydrated alumina 5%

[0073] Low melting point explosion-proof fiber 0.06%

[0074] CASTAMENTFS 200.12%.

[0075] The manufacturing method of this embodiment is the same as that of embodiment 1.

[0076] The main physical and chemical indexes of molten salt furnace castables in this embodiment are:

[0077] Chemical composition: Al 2 O 3 58.7%, SiO 2 40.3%, Fe 2 O 3 0.28%;

[0078] Matrix mineral phase composition: After sintering at 1400°C, the matrix XRD results show that the main crystalline phase is mullite and the secondary crystalline phase is corundum;

[0079] Thermal shock resistance: 58 thermal shocks.

[0080] CO corrosion resistance: The test standard adopts the American "Test Method for Disintegration of Refractories in CO Atmosphere" (ASTMC288). The test result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com