Method for preparing high water dispersibility titanium dioxide

A dispersive and titanium dioxide technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as poor effect, complicated steps, and no rutile titanium dioxide, so as to improve Effect of water dispersibility and high water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

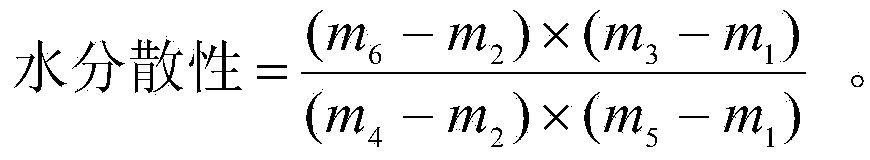

[0019] The method for preparing highly water-dispersible titanium dioxide of the present invention is mainly used for surface treatment of rutile titanium dioxide to improve its water dispersibility. The specific idea of the present invention is to first add a dispersant to improve the dispersion of the titanium dioxide slurry, Phosphorus-containing solution and aluminum-containing solution are used as the coating agent, and then the coating agent is deposited on the surface of titanium dioxide in the form of aluminum phosphate and hydrated alumina, thereby effectively improving the water dispersibility of the product and obtaining titanium with high water dispersibility white powder products. Wherein, the contents described herein are all mass percentage contents, and the means for characterizing the water dispersibility of titanium dioxide in the present invention refer specifically to the water dispersibility detection method in the example, but the present invention is no...

example 1

[0050] Take 1000g of the primary product of rutile titanium dioxide that has not been post-treated, beat it with desalted water, the concentration of the titanium dioxide slurry obtained after beating is 280g / l, heat the titanium dioxide slurry to 50°C; then make the mass concentration 18% The sodium silicate solution is added into the above-mentioned heated titanium dioxide slurry, and stirred evenly, wherein, the addition amount of the sodium silicate solution is the TiO2 in the titanium dioxide slurry 2 0.08% of the mass; then add sodium hexametaphosphate solution, the amount of sodium hexametaphosphate solution is P 2 o 5 Calculate and follow the mass ratio for P 2 o 5 : TiO 2 =2.5:100 calculation, slaking 15min; Add aluminum sulfate solution again, wherein, the add-on of aluminum sulfate solution is with Al 2 o 3 Calculate and follow Al 2 o 3 TiO in titanium dioxide slurry 2 Calculated at 2.5% of the mass, the pH value of the titanium dioxide slurry is controlled ...

example 2

[0052] Take 1000g of the primary product of rutile titanium dioxide that has not been post-treated, and beat it with desalted water. The concentration of the titanium dioxide slurry obtained after beating is 300g / l, and the titanium dioxide slurry is heated to 60°C; then the mass concentration is 18%. The ammonium dihydrogen phosphate solution is added to the above-mentioned heated titanium dioxide slurry, and stirred evenly, wherein, the amount of ammonium dihydrogen phosphate added is the TiO2 in the titanium dioxide slurry 2 0.25% of the mass; then add phosphoric acid solution, the amount of phosphoric acid solution is P 2 o 5 Calculate and follow the mass ratio for P 2 o 5 : TiO 2 =2.0:100 calculation, aging 60min; then add aluminum sulfate solution, wherein, the addition of aluminum sulfate solution is based on Al 2 o 3 Calculate and follow Al 2 o 3 TiO in titanium dioxide slurry 2 Calculated at 1.0% of the mass, the pH value of the titanium dioxide slurry is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com