Method for preparing aluminum oxide with bimodal pore distribution

A technology of alumina and bimodal pores, applied in chemical instruments and methods, catalyst activation/preparation, alumina/aluminum hydroxide, etc., can solve the problems of carrier affecting catalyst performance and low crushing strength, and achieve easy molding, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

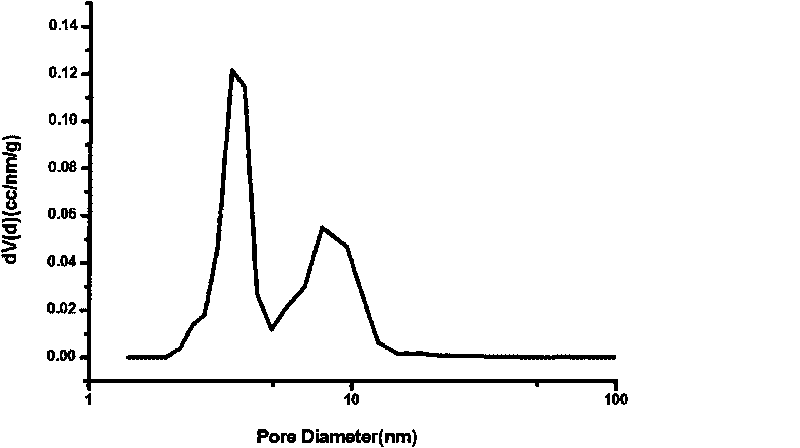

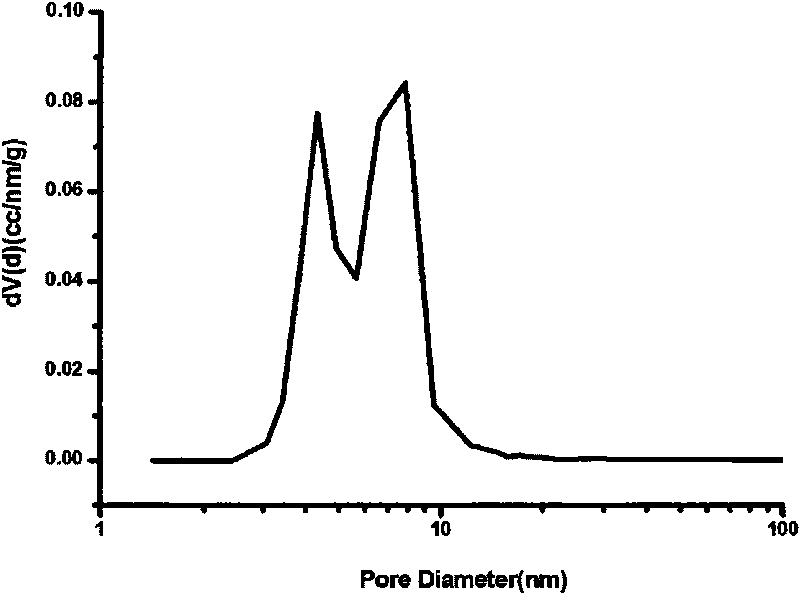

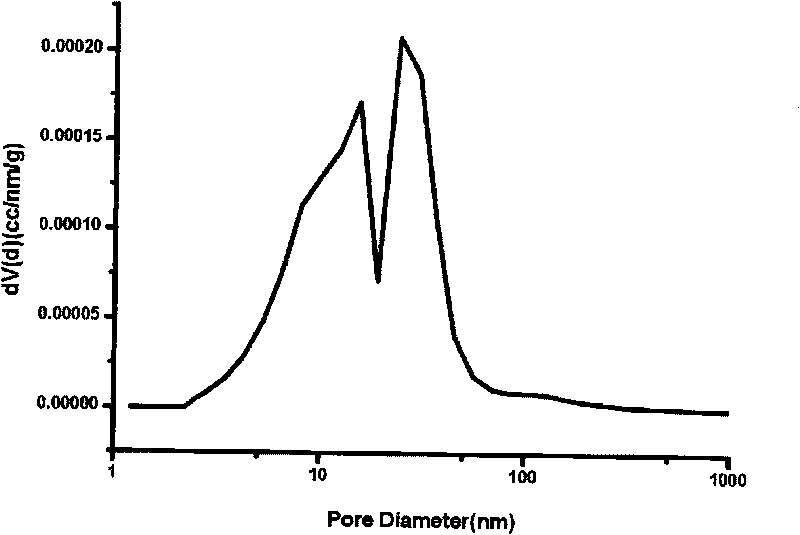

Image

Examples

Embodiment 1

[0028] Add 500 milliliters of water in the stirred kettle, make its temperature reach 55 ℃, then add concentration and be 0.3 liters of aluminum sulfate of 20%. Using the co-current feeding method, 1.5 liters of aluminum sulfate with a concentration of 20% and 1500 grams of sodium metaaluminate solution with a concentration of 200 grams of alumina / liter are neutralized, and the pH value is controlled at 7.5. During the reaction, cooling water was circulated through the jacket of the kettle to keep the solution temperature at 25°C. Aged for 4 hours, then washed 5 times with 20 liters of deionized water, and the obtained filter cake was dried at 150°C for 4 hours to obtain the raw material alumina hydrate A1

Embodiment 2

[0030] Add 500 milliliters of water into the stirred tank, control the reaction temperature to be 45°C, and control the pH value to be 6.5, adopt the co-current feeding method, 1 liter of nitric acid with a concentration of 20% and a sodium metaaluminate solution with a concentration of 150 grams of alumina / liter 2000g for neutralization, aged for 1 hour, and then washed 5 times with 20 liters of deionized water, and the obtained filter cake was dried at 120°C for 2 hours to obtain the raw material alumina hydrate A2

Embodiment 3

[0032] Control the reaction temperature to 75°C, control the pH value to 9.5, adopt the co-current feeding method, neutralize 1 liter of nitric acid with a concentration of 20% and 1000 grams of sodium metaaluminate solution with a concentration of 200 grams of alumina / liter, and age for 0.5 hours , and then washed 5 times with 20 liters of deionized water, and the obtained filter cake was dried at 120°C for 2 hours to obtain the raw material alumina hydrate B1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com