Full-automatic environment-friendly collecting box high-pressure cleaning machine

A technology of high-pressure cleaners and collection boxes, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as easy to cause foul odor, difficult cleaning, and unrecyclable cleaning water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

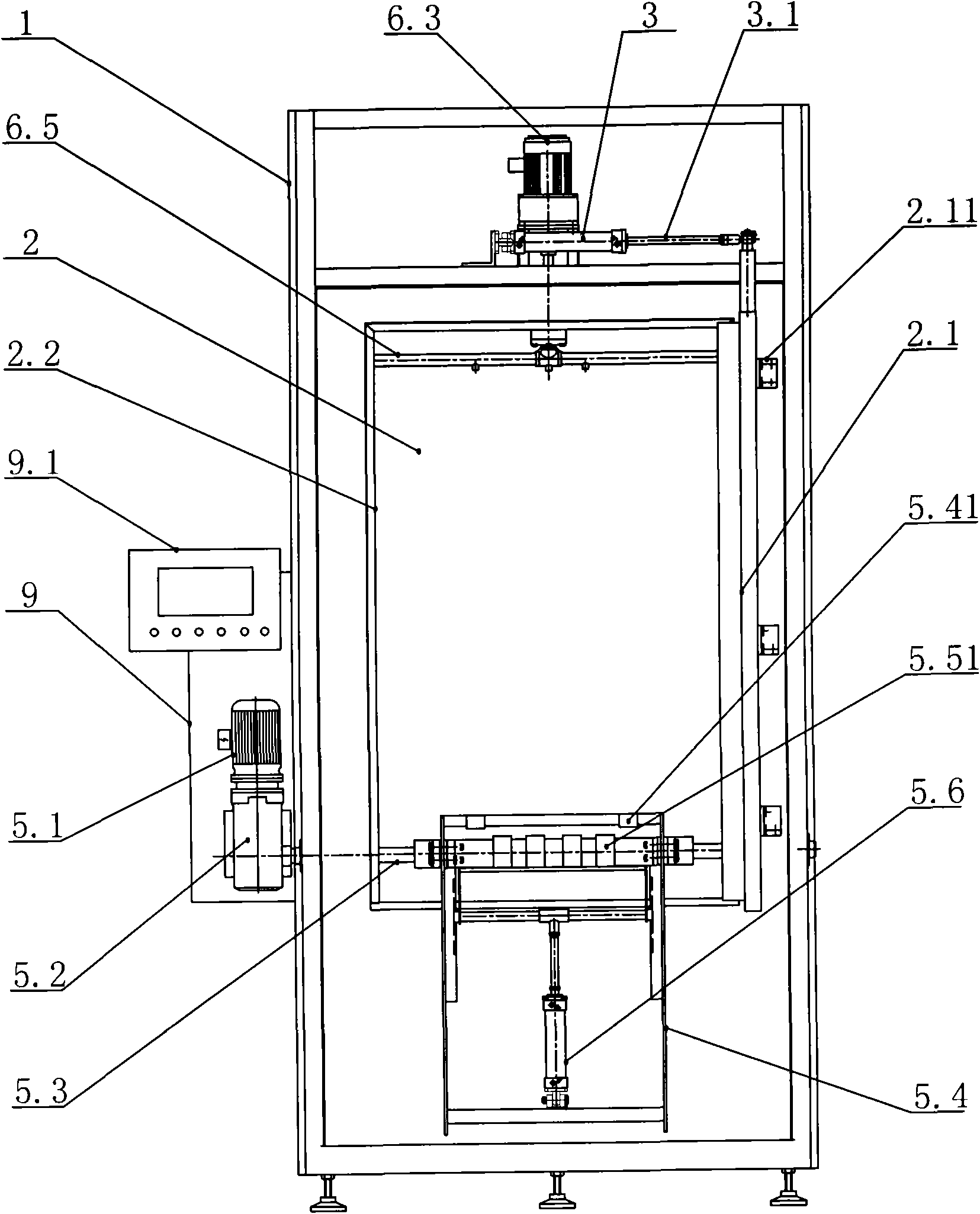

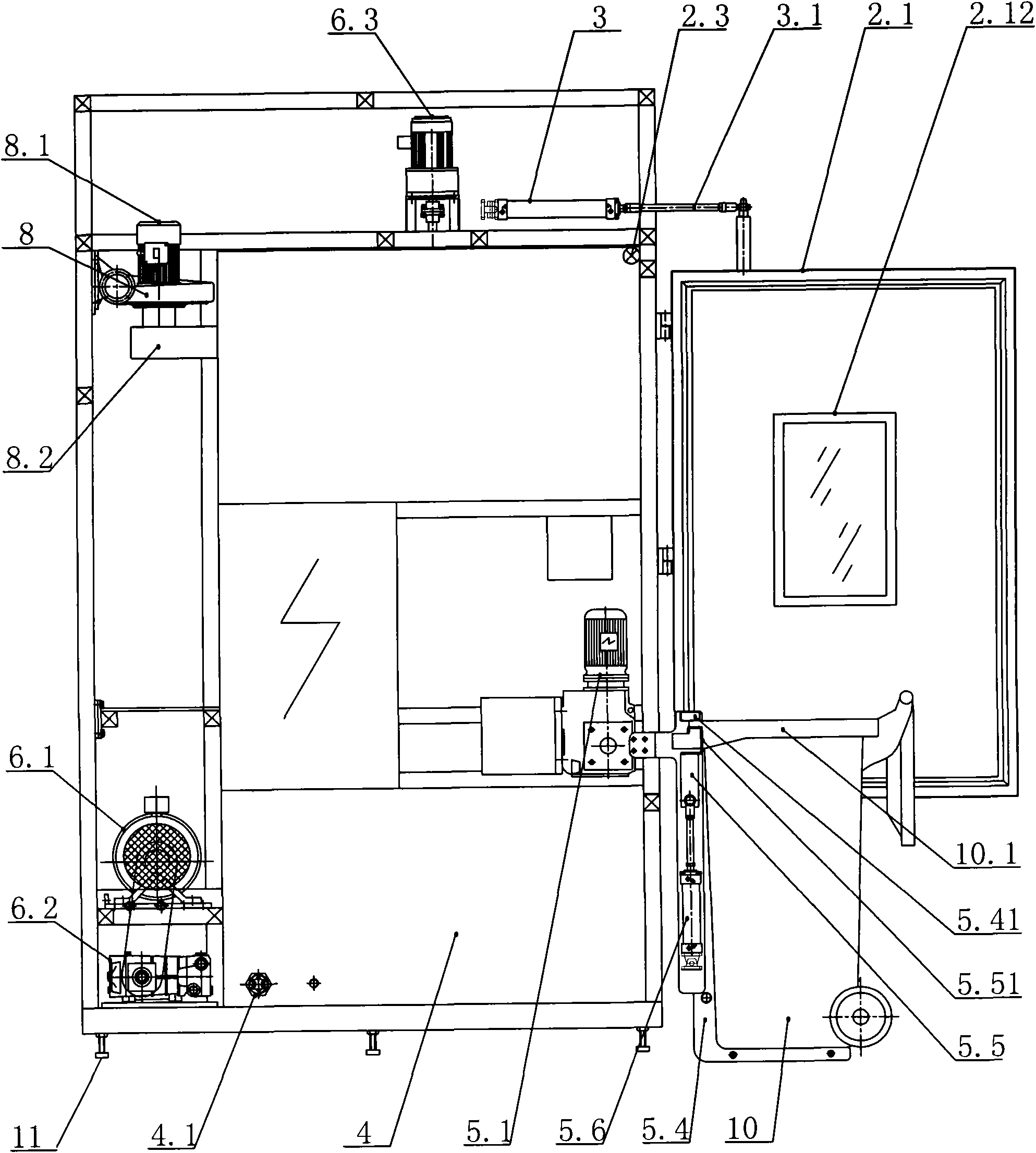

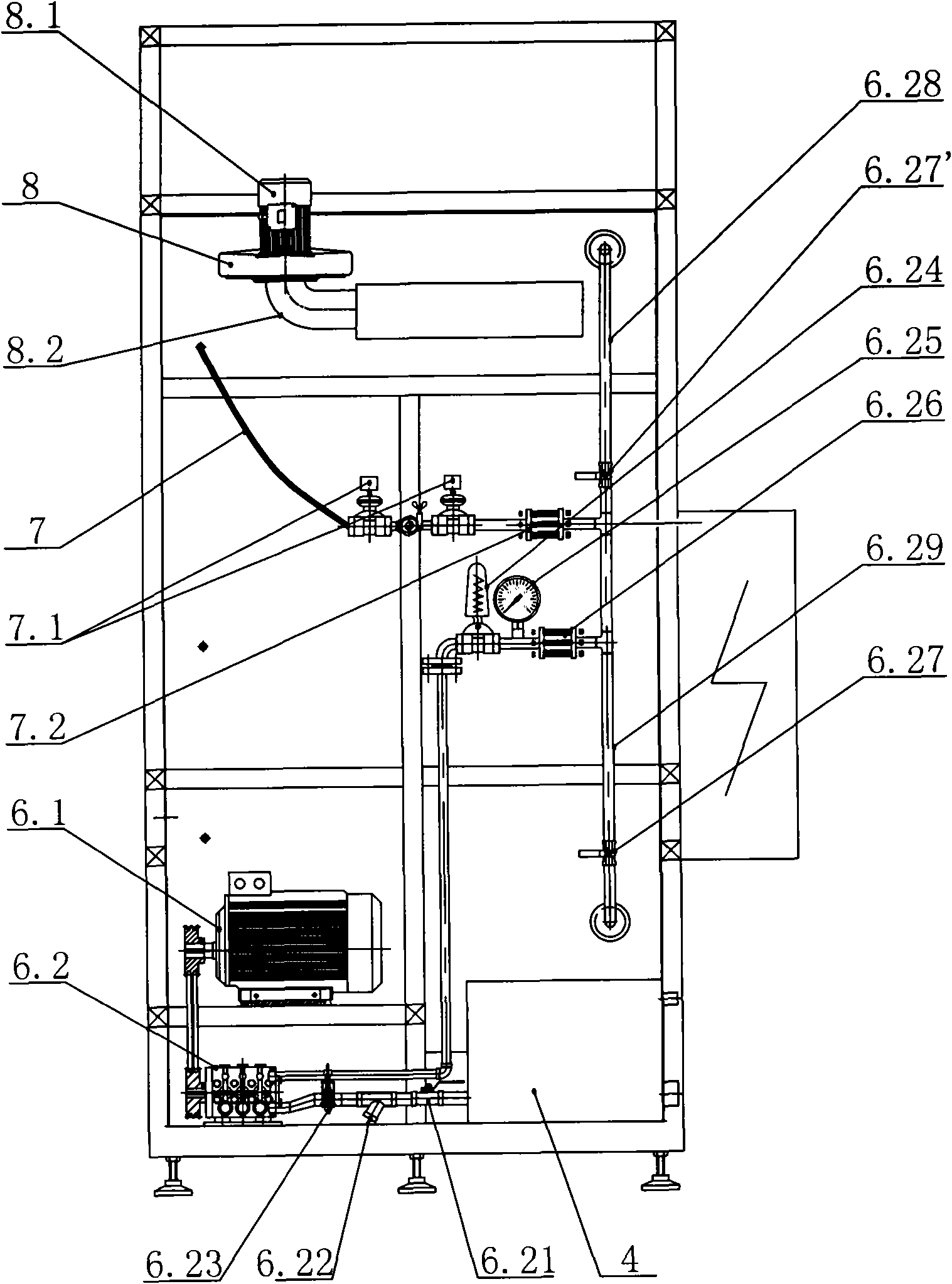

[0025] Such as figure 1 As shown, a kind of automatic environment-friendly collection box high-pressure cleaning machine provided by the present invention includes a box body composed of a frame 1 and a closed washing room 2 located in the box body, an environment-friendly collection box clamping and turning mechanism, and an environment-friendly collection box. The spray mechanism for cleaning the box; the front wall of the washing room 2 is equipped with a sealed door 2.1, and the sealed door 2.1 is hinged on the door frame 2.2 of the washing room through the door hinge 2.11. An electric control cabinet 9 and an operation panel 9.1 are hung on the side of the box body, and machine feet 11 are provided at the bottom of the box body.

[0026] Such as Figure 7As shown, the clamping and turning mechanism of the environmental protection collection box includes a turning motor 5.1, a turning motor reducer 5.2, a turning shaft 5.3, a turning frame 5.4, a moving frame 5.5 and a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com