Method for determining performance of automatic optical detection equipment and standard film

A technology for automatic optical detection and equipment performance, which is applied in the direction of material analysis, measuring devices, scientific instruments, etc. by optical means, which can solve the problems of high scrap rate of PCB boards and reduced accuracy of PCB boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

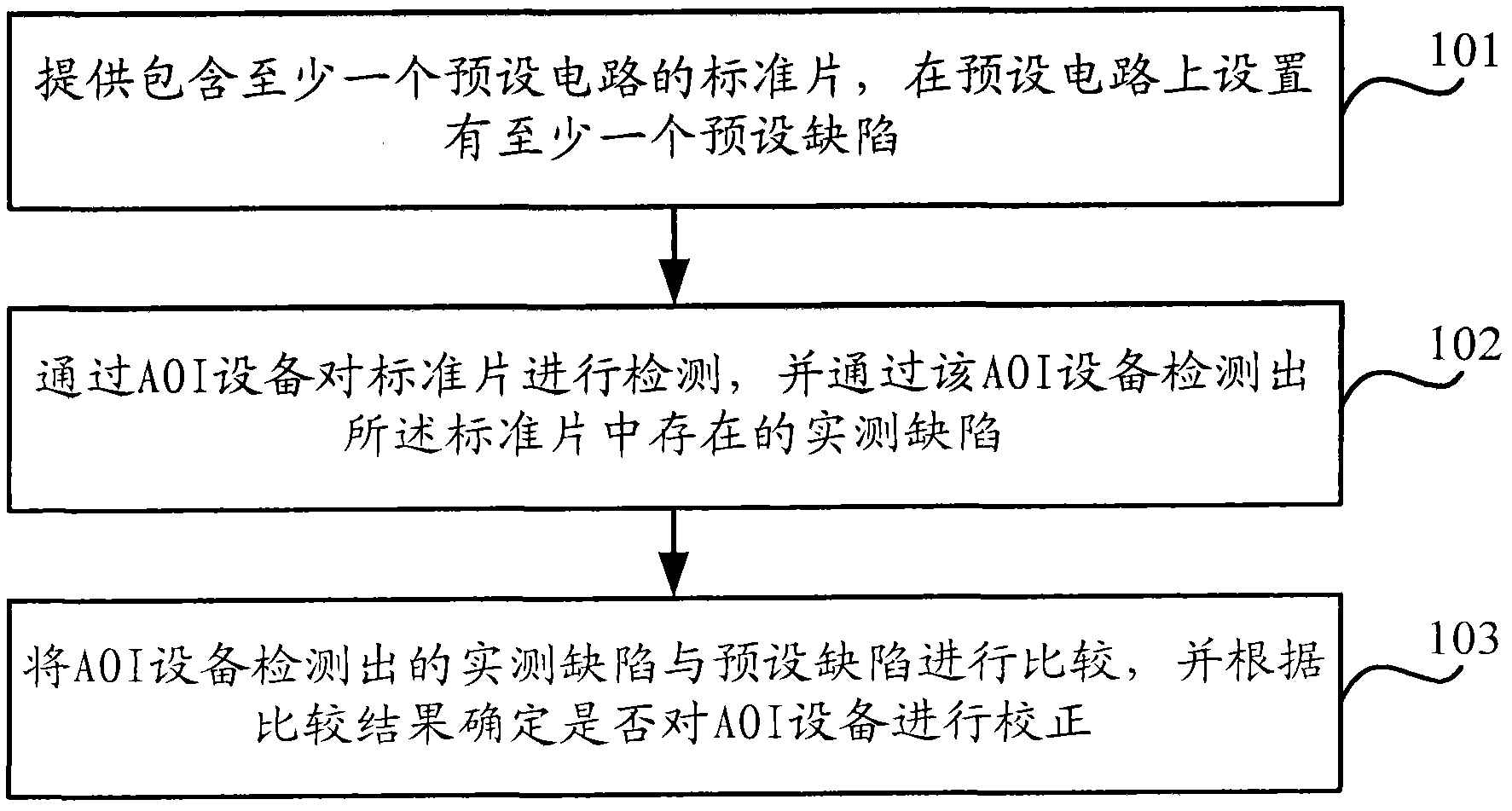

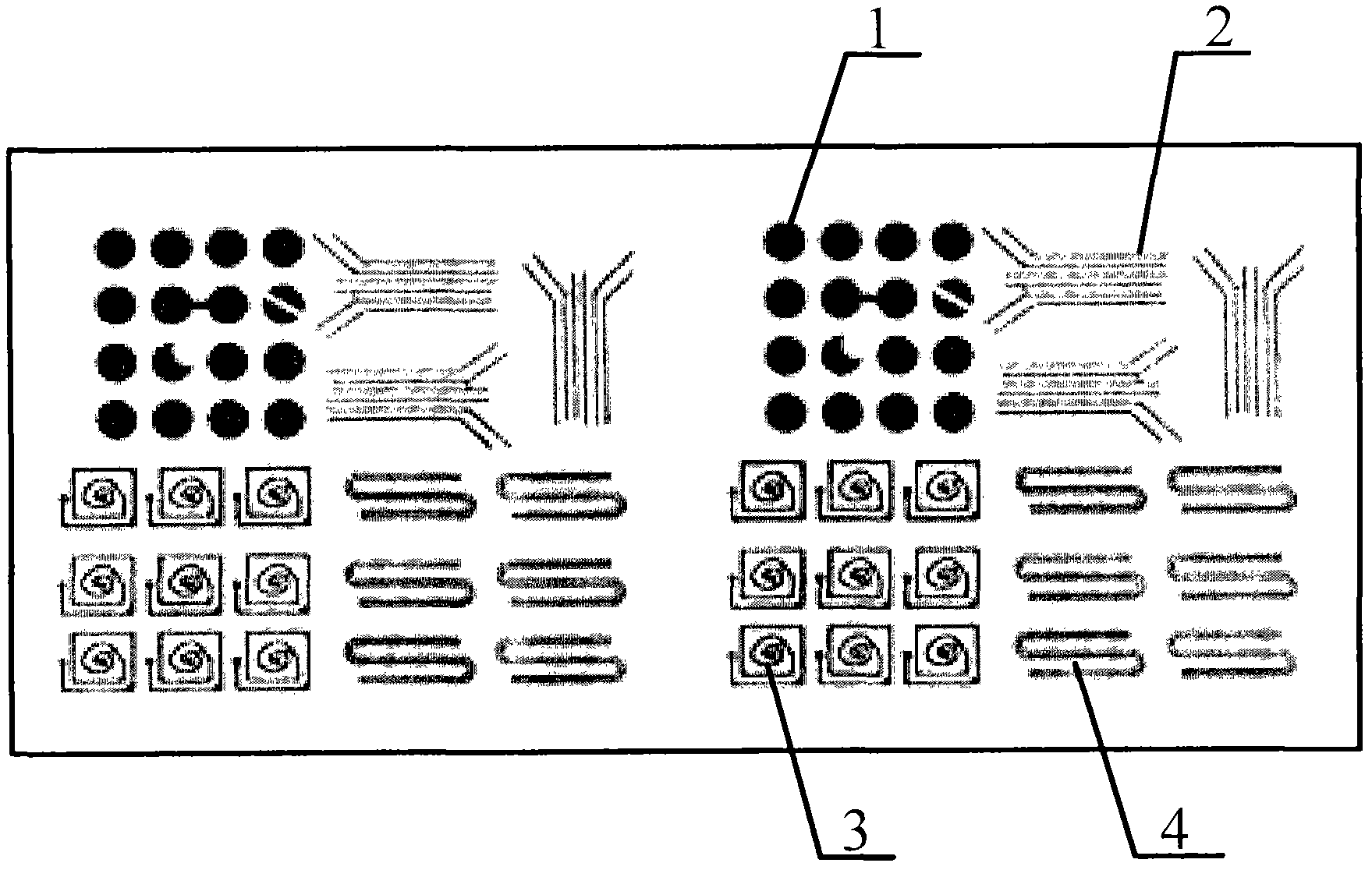

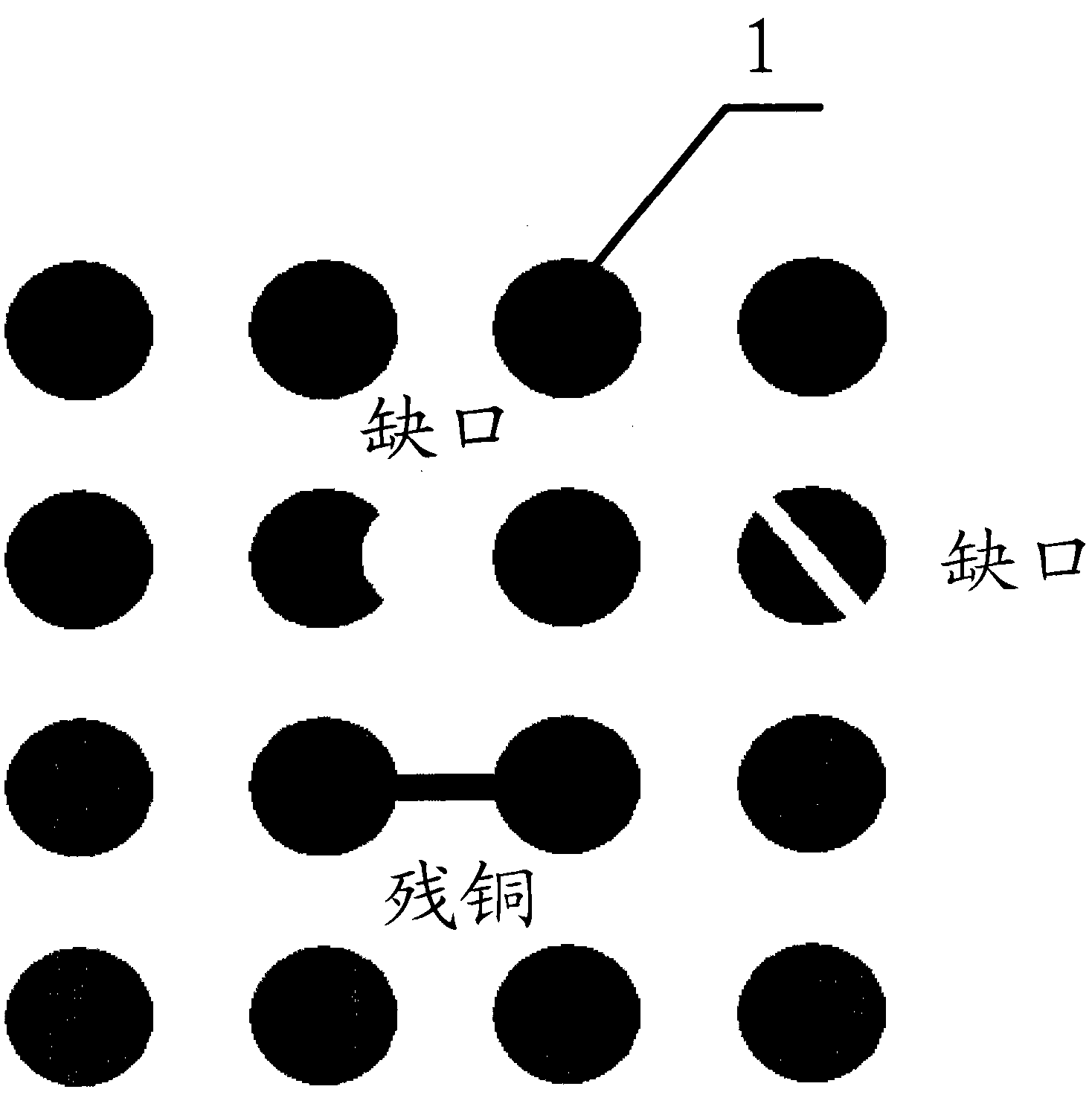

[0019] In view of the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a method for determining the performance of AOI equipment, the method comprising: providing a standard sheet containing at least one preset circuit, and at least one preset circuit is provided on the preset circuit Defects: the standard sheet is detected by the AOI equipment, and the measured defects in the standard sheet are detected by the AOI equipment; the measured defects are compared with the preset defects, and the comparison results are used to Determine whether to calibrate the AOI equipment. By adopting the technical scheme of the present invention, the performance of the AOI equipment is detected, and it is determined whether to correct the AOI equipment according to the detection results, so as to ensure the detection performance and stability of the AOI equipment, thereby improving the ability of the AOI equipment to detect the PCB boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com