AOI (Automated Optical Inspection) station capable of conveying and automatically loading and unloading PCBs (Printed Circuit Board) in parallel by two lines

A PCB board and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of slow production efficiency, heavy labor, and defective products, and achieve the effect of convenient picking and placing of PCB boards and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

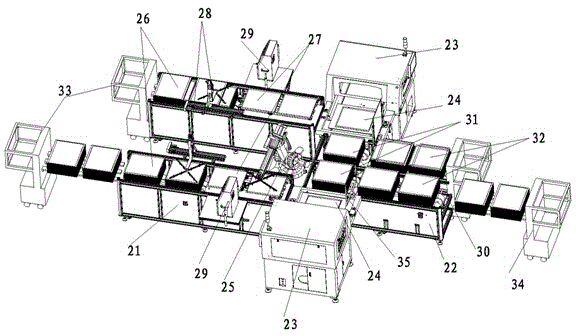

[0020] Such as figure 1 As shown, an AOI station for automatic upper and lower PCB boards is conveyed in parallel by two lines. An automatic optical inspection machine 23 is provided, and a water platform 24 is provided at the inlets of the two automatic optical inspection machines 23, and the outlet of one of the PCB board feeding conveying lines 21 is docked on one of the horizontal platforms 24, and the other The discharge port of one PCB board feeding conveying line 21 is docked on another horizontal platform 24 , and a multi-joint handling manipulator 25 is arranged between the two PCB board feeding conveying lines 21 .

[0021] Preferably, the PCB board feeding conveyor line 21 is provided with an incoming material waiting area 26 and an outgoing material waiting area 27, and a PCB board taking manipulator 28 is provided between the incoming material waiting area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com