System and method for detecting defects of blind holes in PCB (Printed Circuit Board) bare board based on AOI (Automated Optical Inspection)

A detection system and detection method technology, applied in image data processing, instruments, calculations, etc., can solve the problem of low blind hole detection accuracy, and achieve the effects of reducing noise interference, reducing system cost, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

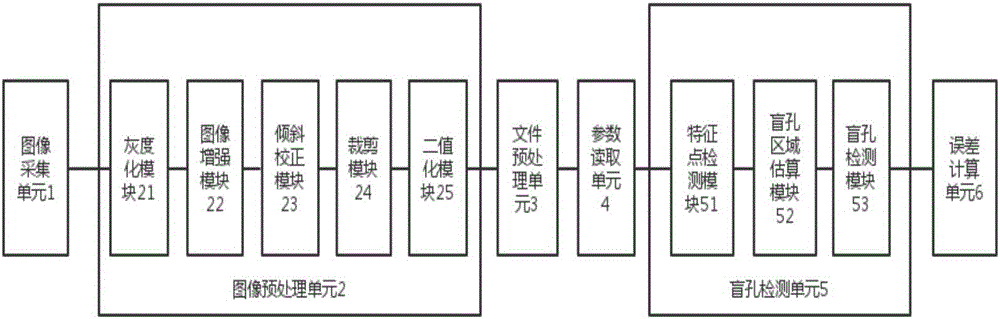

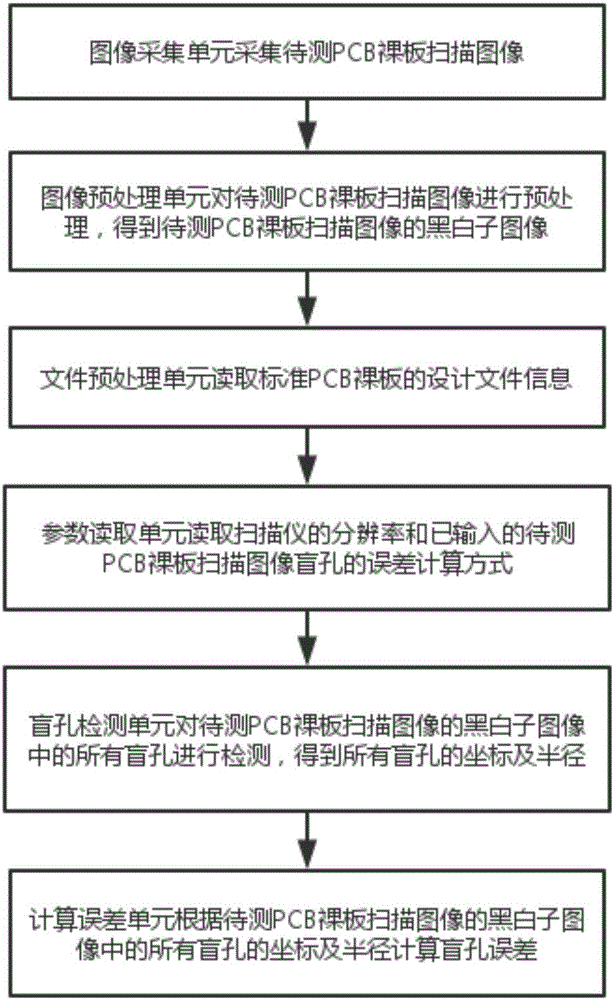

[0039] refer tofigure 1 , the detection system of the present invention includes an image acquisition unit, an image preprocessing unit, a file preprocessing unit, a parameter reading unit, a blind hole detection unit and an error calculation unit connected in sequence, wherein:

[0040] An image acquisition unit, configured to acquire a scanned image of a bare PCB to be tested;

[0041] An image preprocessing unit is used to preprocess the scanned image of the PCB bare board to be tested;

[0042] The file preprocessing unit is used to read the coordinate value representation form, mounting hole information and blind hole information in the standard PCB bare board design file;

[0043] The parameter reading unit is used to read the resolution of the scanner and the error calculation method of the blind hole of the scanned image of the PCB ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com