Detection mechanism with side light source configured for annular light source and backlight source for AOI (Automated Optical Inspection) visual inspection

A ring light source and visual detection technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as insufficient lighting and uneven lighting, and achieve good lighting effects and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

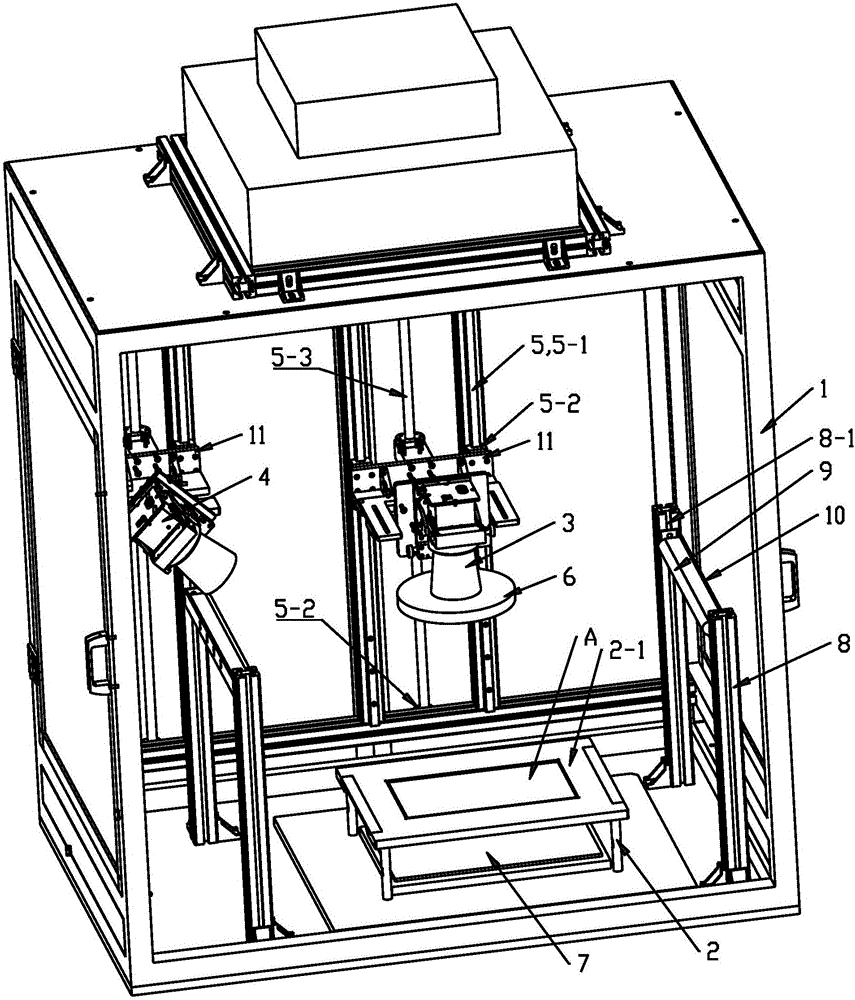

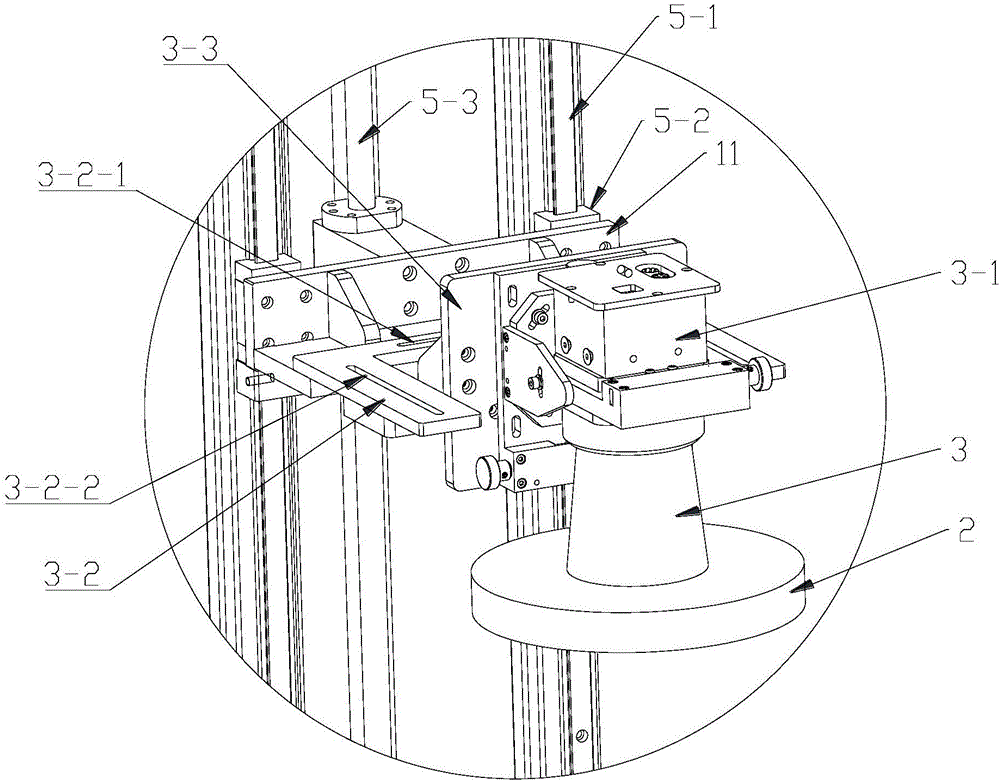

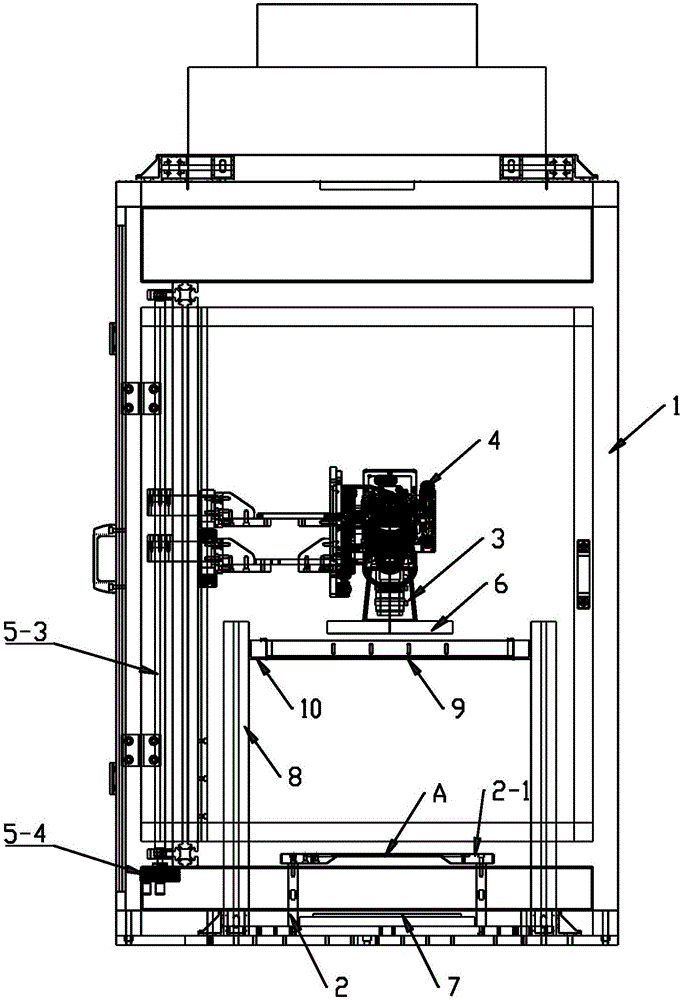

[0027] Example: such as Figure 1 to Figure 3 As shown, a ring light source for AOI visual inspection is equipped with a side light source and a backlight detection mechanism, including a bracket 1 and a CCD camera. The bracket 1 has a detection area, and the bracket 1 is provided with a support frame 2 in the detection area. 2 The top is provided with a mounting bracket 2-1 for fixing the product A to be inspected, and a backlight 7 is provided directly below the bracket 1 relative to the product A to be inspected. The CCD camera includes a front view CCD camera 3 located directly above the inspection area and The side viewing angle CCD camera 4 that is positioned at the detection area side, described positive viewing angle CCD camera 3 is installed and fixed with the annular light source 6 below its lens, and described support 1 is respectively provided with for facing toward the left and right side top of support frame 2. The high-angle strip light source 9 for lighting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com