AOI (automated optical inspection) device with multiple area-array cameras and image shooting method thereof

An area array camera and equipment technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem that AOI equipment is difficult to meet the speed requirements, increase the complexity and cost of the system, and enlarge the field of view of the area array camera, etc. Problems, to achieve the effect of reducing the time of camera shooting, taking pictures and scanning quickly, and reducing the time of camera movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

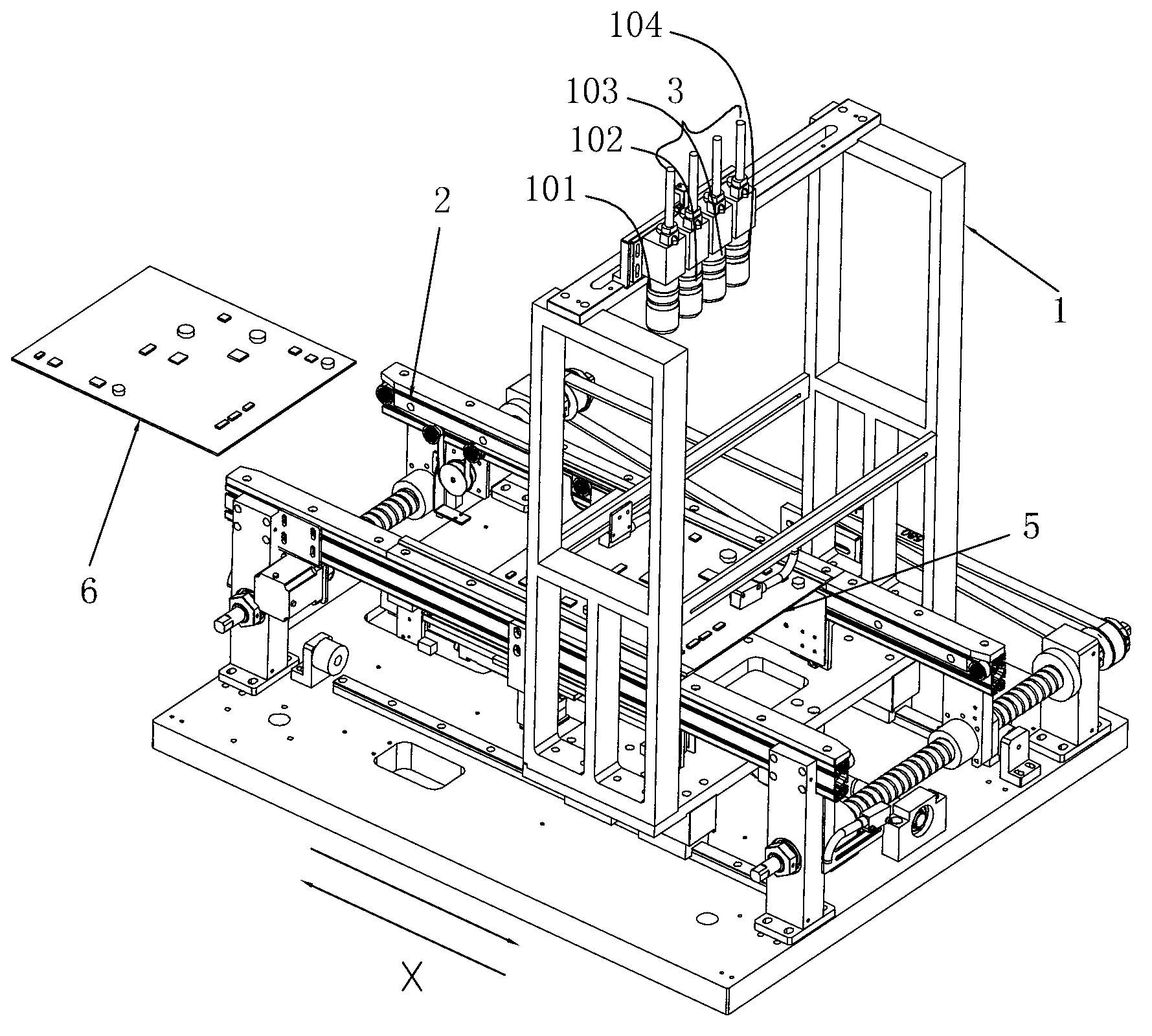

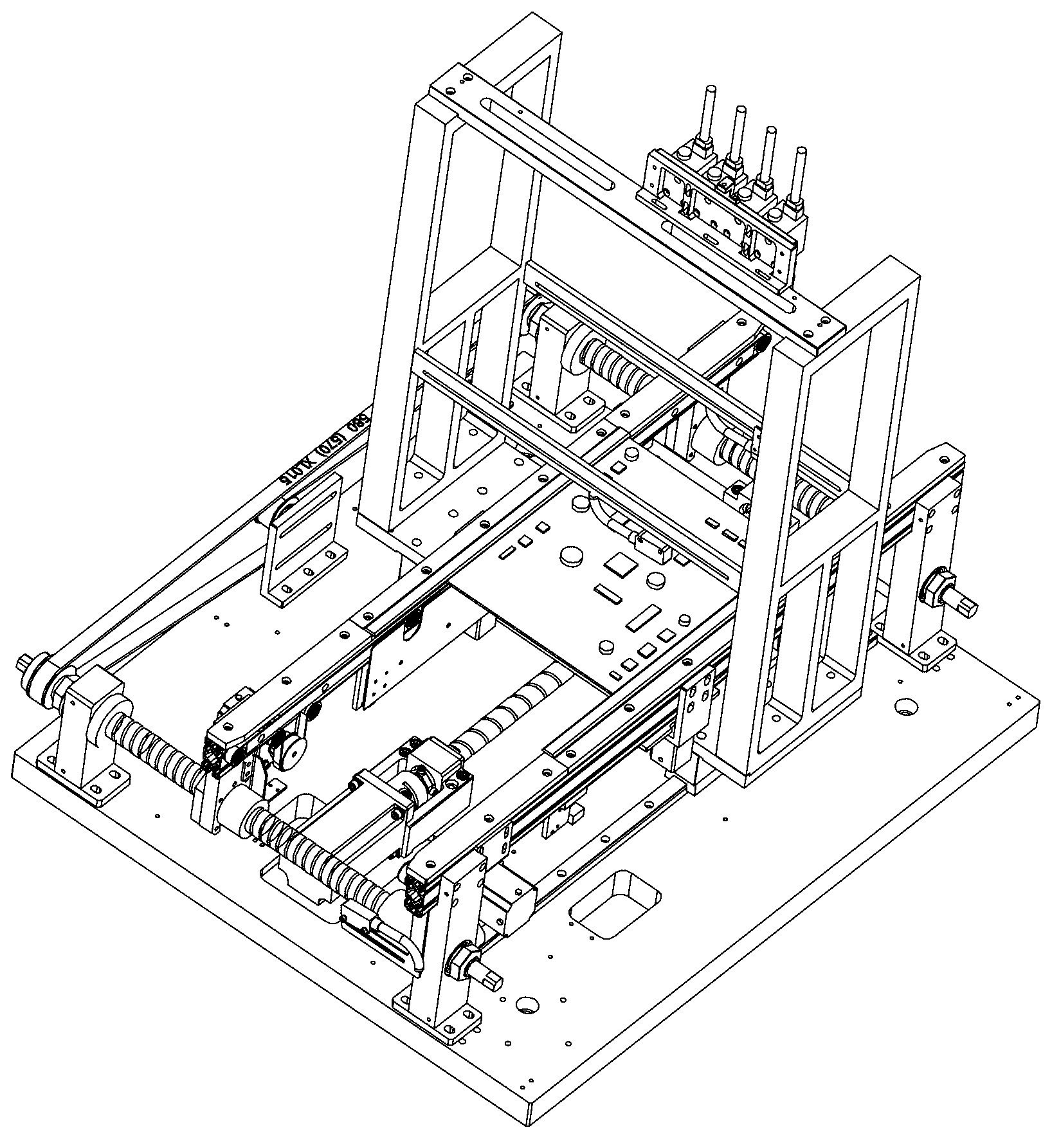

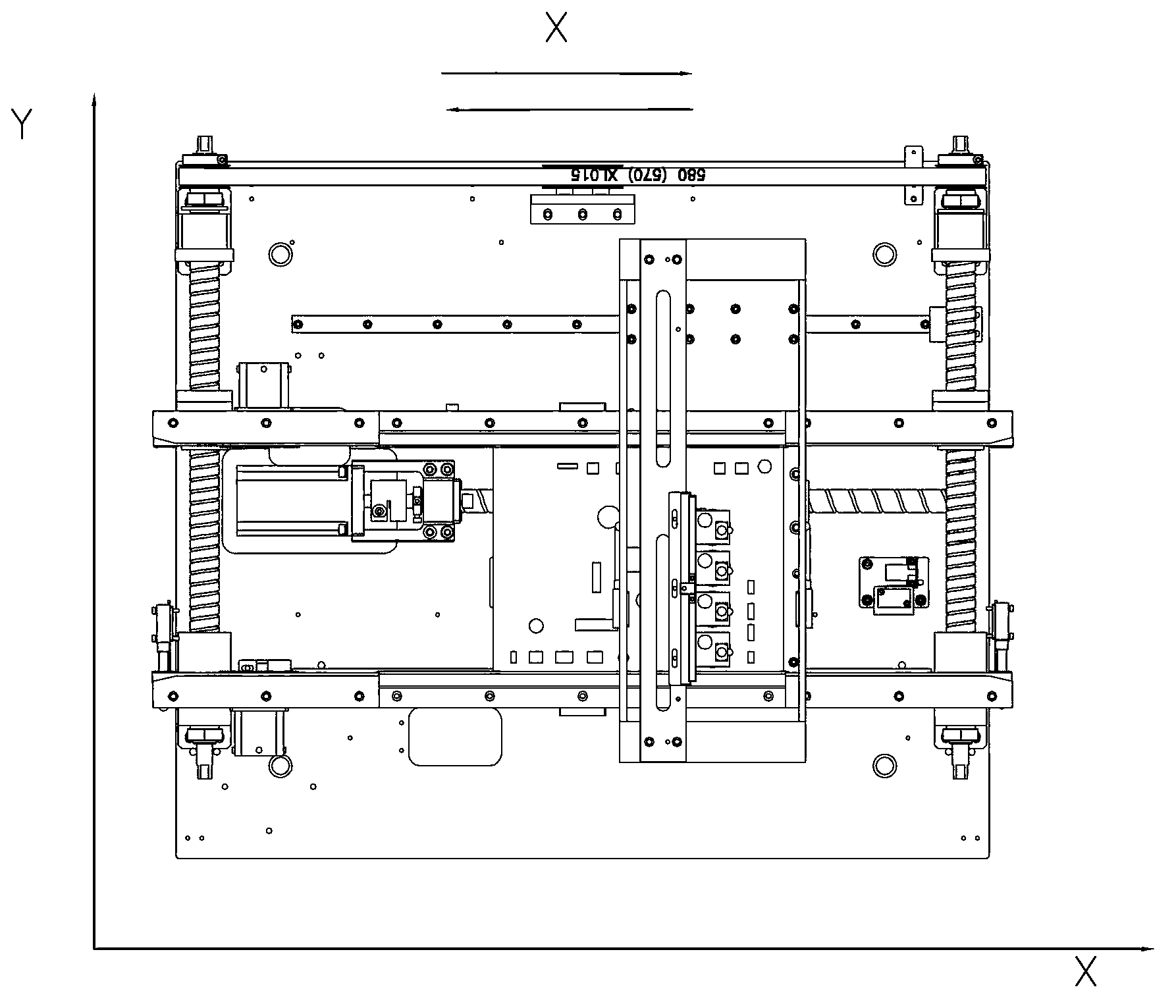

[0030] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the multi-array camera AOI equipment includes a camera frame 1 that can move in the X-axis direction of the equipment, and a transmission mechanism 2 that transmits PCB boards to the stage. The track direction of the transmission mechanism is taken as the X-axis direction of the equipment. Described camera frame 1 is provided with camera array, and camera array 3 is made of at least two area array cameras, and the shooting direction of each area array camera is in the same direction, and the FOV of adjacent two area array cameras has overlapping area 4 (as overlapping 1-5mm) , also includes a controller that controls each area array camera to take images of the PCB board at the same time, and a processor that stitches the images captured by each camera into one image. The processor can be a computer device or a single-chip microcomputer or other conventional image processing device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com