Method for detecting leakproofness of boiler

A detection method and tightness technology, applied in the field of boiler tightness detection, can solve the problems of lack of inspection means, low efficiency of tightness inspection, small inspection scope, etc. The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

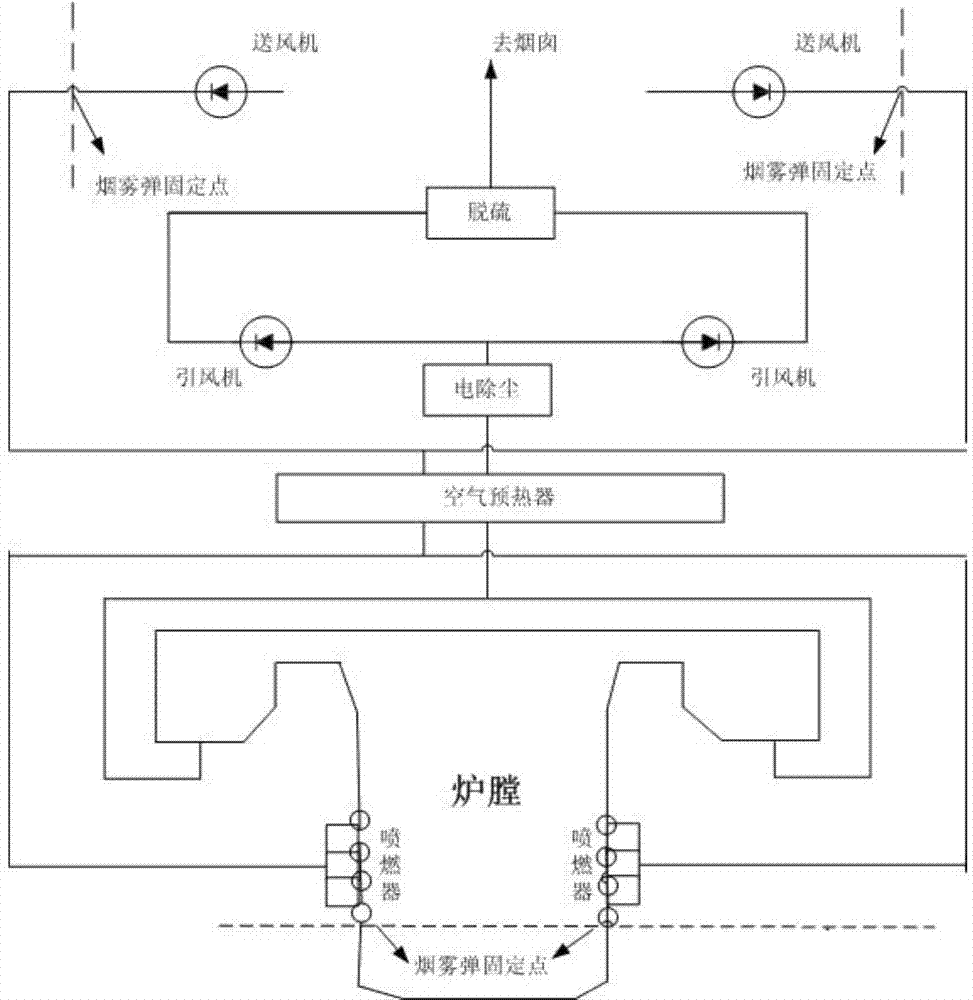

Embodiment 1

[0020] Install 8 and 60 colored smoke bombs at the outlet of the boiler blower and the outlet of the burner respectively, start the blower and the induced draft fan to increase the pressure of the boiler furnace, increase the gauge pressure in the boiler furnace to 300Pa, and ignite the outlet of the boiler blower Colored smoke bombs. Then the gauge pressure in the boiler furnace is raised to 600Pa, and 6 colored smoke bombs at the outlet of the burner are ignited every 2 minutes, and the points are finished in 10 times. Check and mark the discharge point of the colored smoke outside the boiler, which is the air leakage point of the boiler furnace and tail flue, and arrange maintenance forces to deal with the marked air leakage point.

[0021] After repairing the marked air leakage point, run the boiler equipment again, and set the pressure in the boiler furnace to 300Pa, and find that the gauge pressure in the boiler furnace is stable at 300Pa, indicating that the air leakage...

Embodiment 2

[0023] Install 30 colored smoke bombs and 40 colored smoke bombs at the outlet of the boiler blower and the outlet of the burner respectively, start the blower and the induced draft fan to increase the pressure of the boiler furnace, increase the gauge pressure in the boiler furnace to 250Pa, and ignite the outlet of the boiler blower Colored smoke bombs. Then the gauge pressure in the boiler furnace is raised to 520Pa, and the colored smoke bombs at the outlet of 5 burners are ignited every 2 minutes, and the points are finished in 8 times. Check and mark the discharge point of the colored smoke outside the boiler, which is the air leakage point of the boiler furnace and tail flue, and arrange maintenance forces to deal with the marked air leakage point.

[0024] After repairing the marked air leakage point, run the boiler equipment again, and set the pressure in the boiler furnace to 300Pa, and find that the gauge pressure in the boiler furnace is stable at 300Pa, indicating...

Embodiment 3

[0026] Set 15 colored smoke bombs and 20 colored smoke bombs at the outlet of the boiler blower and the outlet of the burner respectively, start the blower and the induced draft fan to increase the pressure of the boiler furnace, raise the gauge pressure in the boiler furnace to 200Pa, and ignite the outlet of the boiler blower Colored smoke bombs. Then the gauge pressure in the boiler furnace is raised to 500Pa, and 4 colored smoke bombs at the outlet of the burner are ignited every 2 minutes, and the points are finished in 5 times. Check and mark the discharge point of the colored smoke outside the boiler, which is the air leakage point of the boiler furnace and tail flue, and arrange maintenance forces to deal with the marked air leakage point.

[0027] After repairing the marked air leakage point, run the boiler equipment again, and set the pressure in the boiler furnace to 300Pa, and find that the gauge pressure in the boiler furnace is stable at 300Pa, indicating that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com