Method for sintering vanadium-titanium magnetite concentrate at high negative pressure and high air quantity

A technology of vanadium-titanium magnetite concentrate and large air volume, which is applied in the field of metallurgy, can solve the problems of poor technical and economic indicators of smelting blast furnaces, and achieve the effects of increasing production and reducing air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

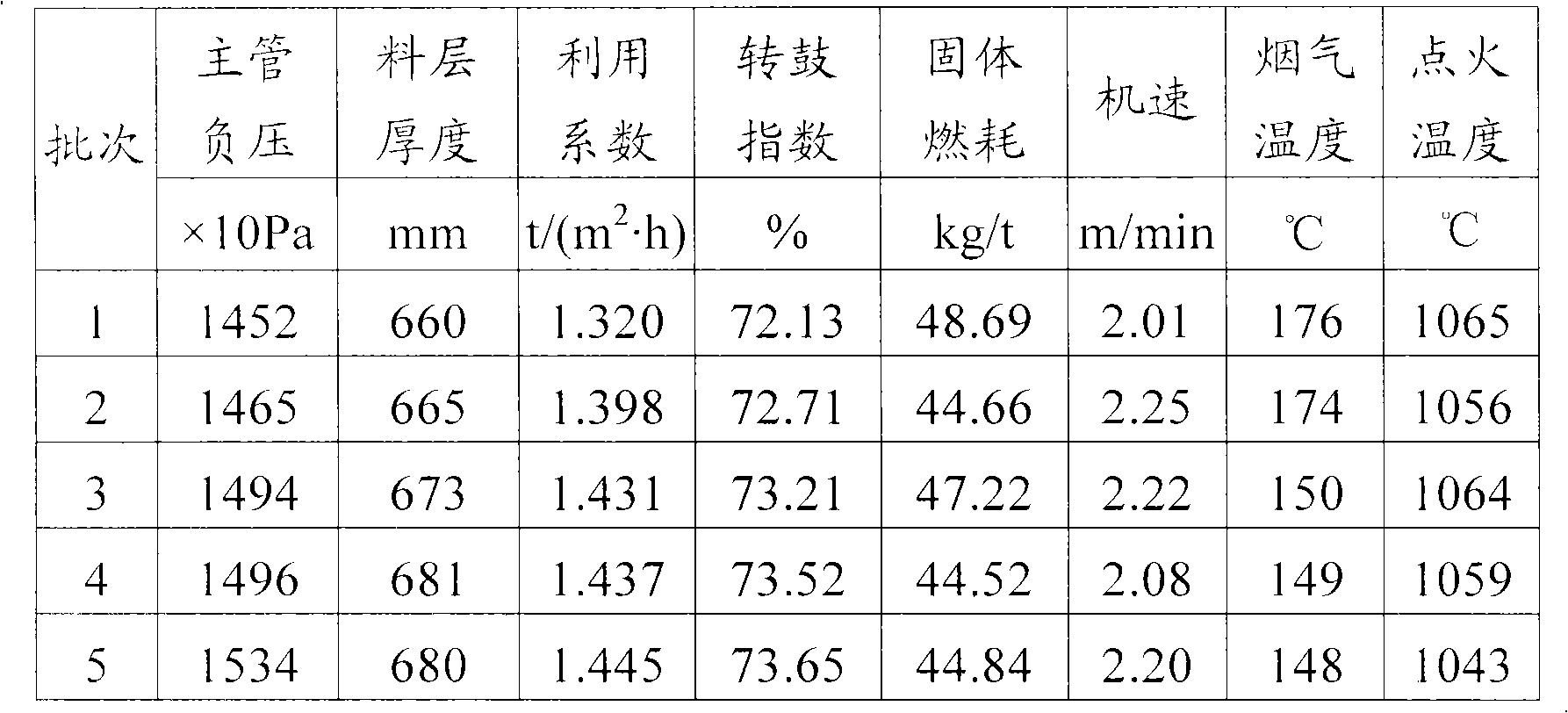

Examples

Embodiment 1

[0036] 1. Adopt high negative pressure fan and large air volume fan

[0037] (1) 2 main exhaust fans:

[0038] Air volume: 19800m 3 / min(working condition)

[0039] Fan inlet negative pressure: 16500Pa

[0040] Air volume per unit sintering area: Q=2×19800 / 360=110m 3 / (m 2 min)

[0041] (2) Head electrostatic precipitator

[0042] In view of the strict requirements of high negative pressure fans on dust concentration, two 330m 2 Horizontal three-electric field electrostatic precipitator, which can reduce the concentration of flue gas dust to 80mg / m 3 Next, protect the hood rotor.

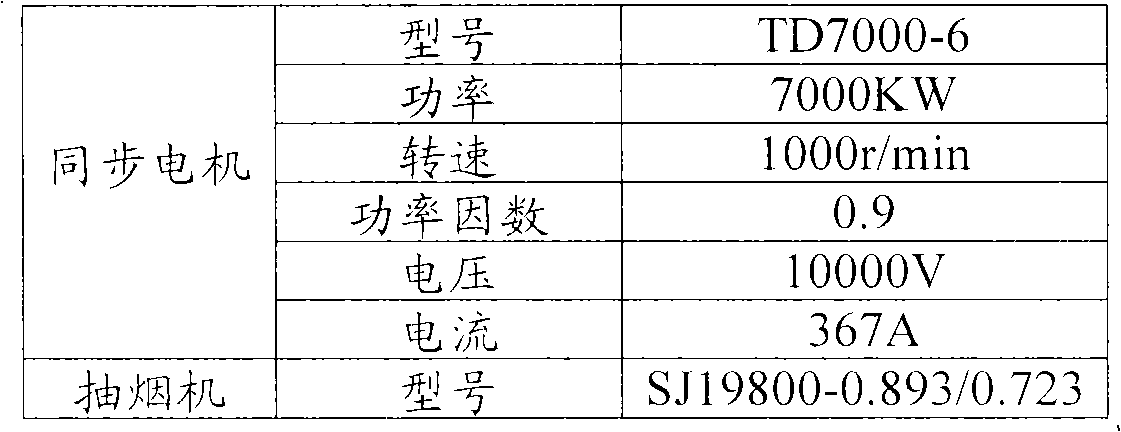

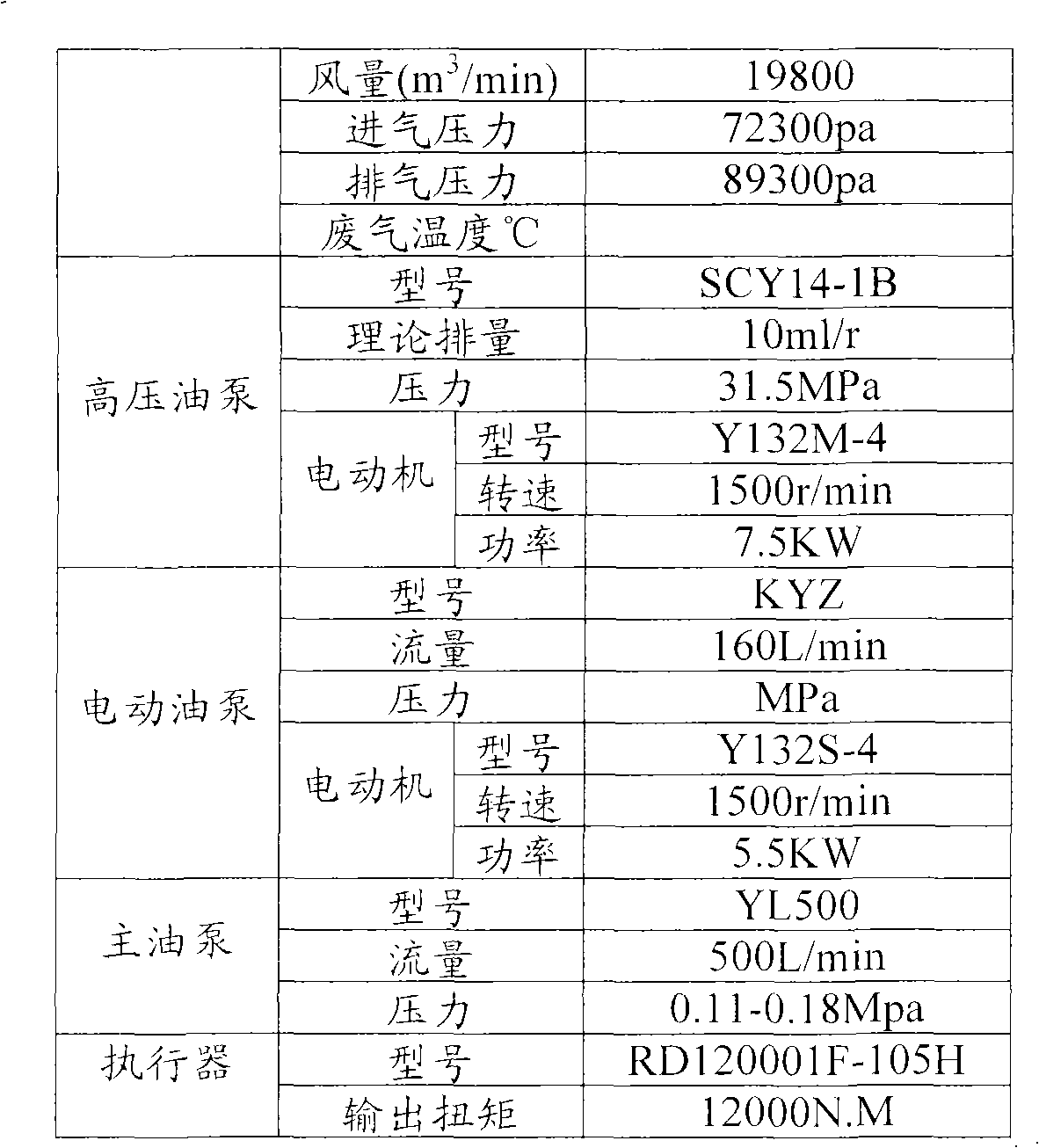

[0043] Table 1 below lists the technical performance indicators of the high negative pressure equipment used in Embodiment 1 of the present invention.

[0044] Table 1 Technical performance of high negative pressure fan equipment

[0045]

[0046]

[0047] 2. Main exhaust system

[0048] The main exhaust system is composed of the main exhaust fan bellows, air collecting pipe, head e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com